Solar loop heat pipe system with highly changed heat pipe pipe-diameter for microbial soil purifying

A solar energy loop and soil purification technology, applied in the field of solar energy and heat pipes, can solve problems such as failure to save energy, and achieve the effects of improving heat transfer effect, heat transfer coefficient, and soil remediation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0049] In this article, if there are no special instructions, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

[0050] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

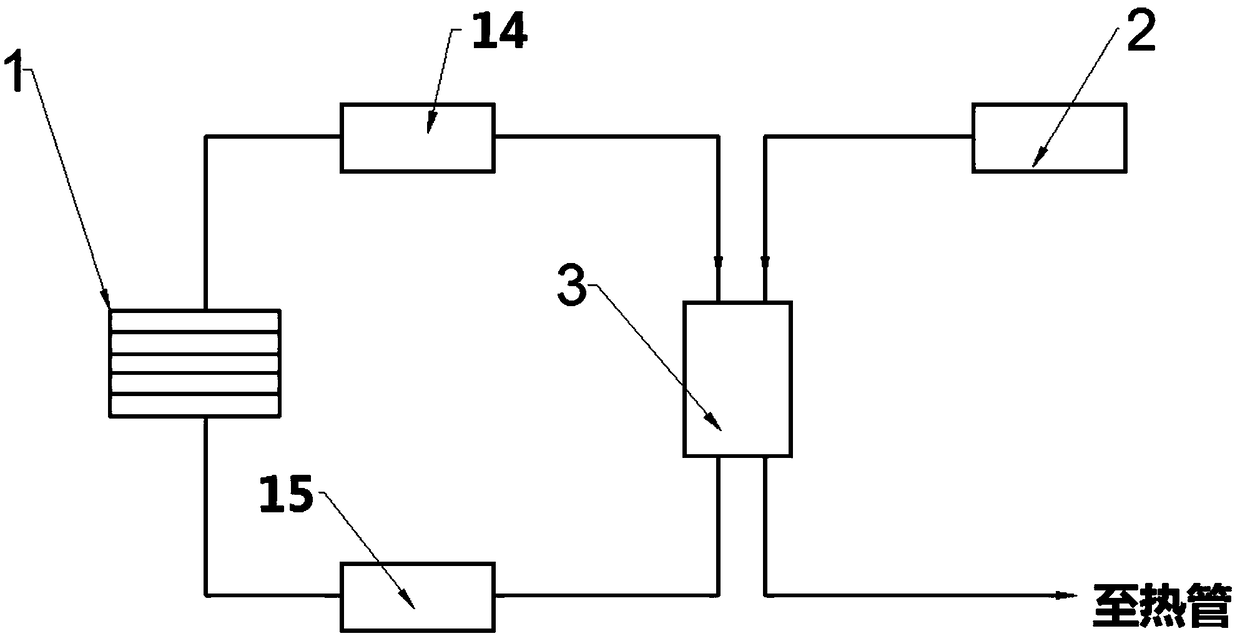

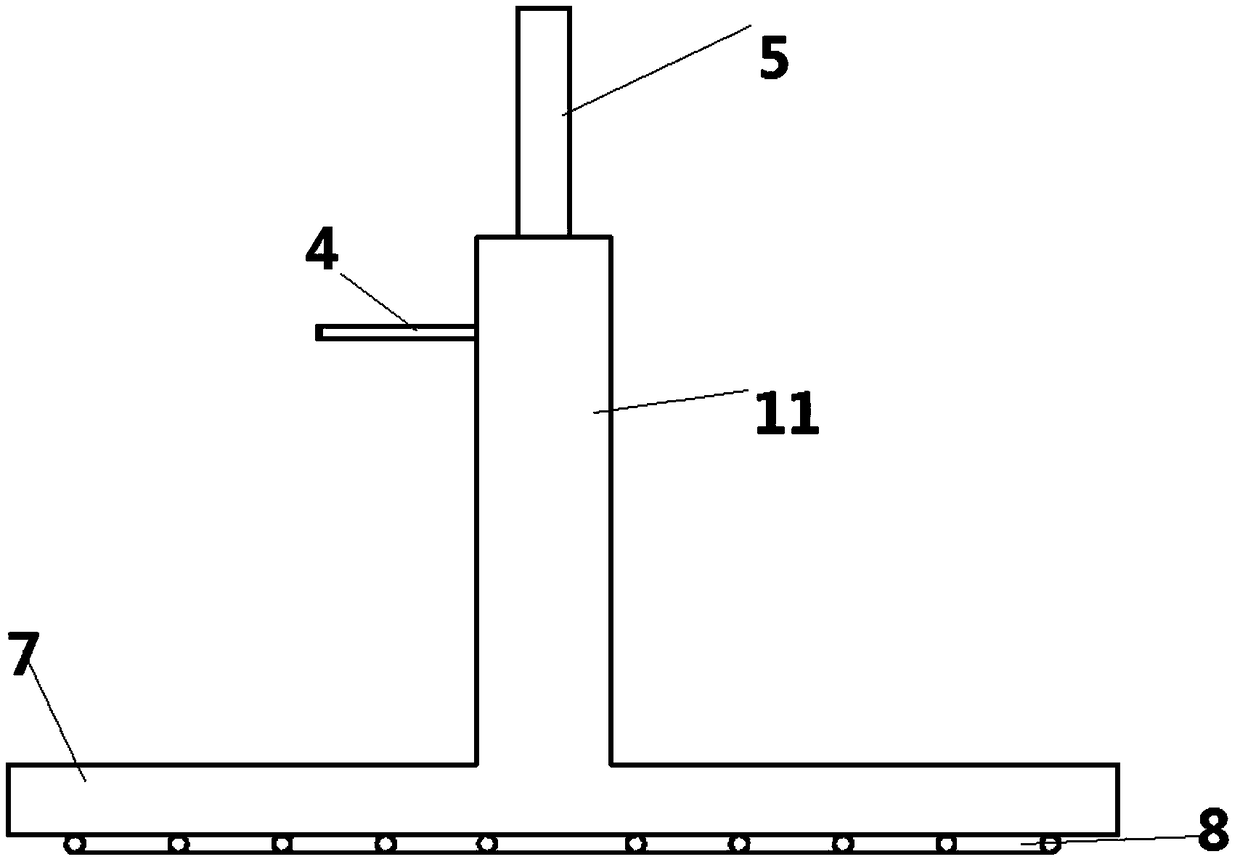

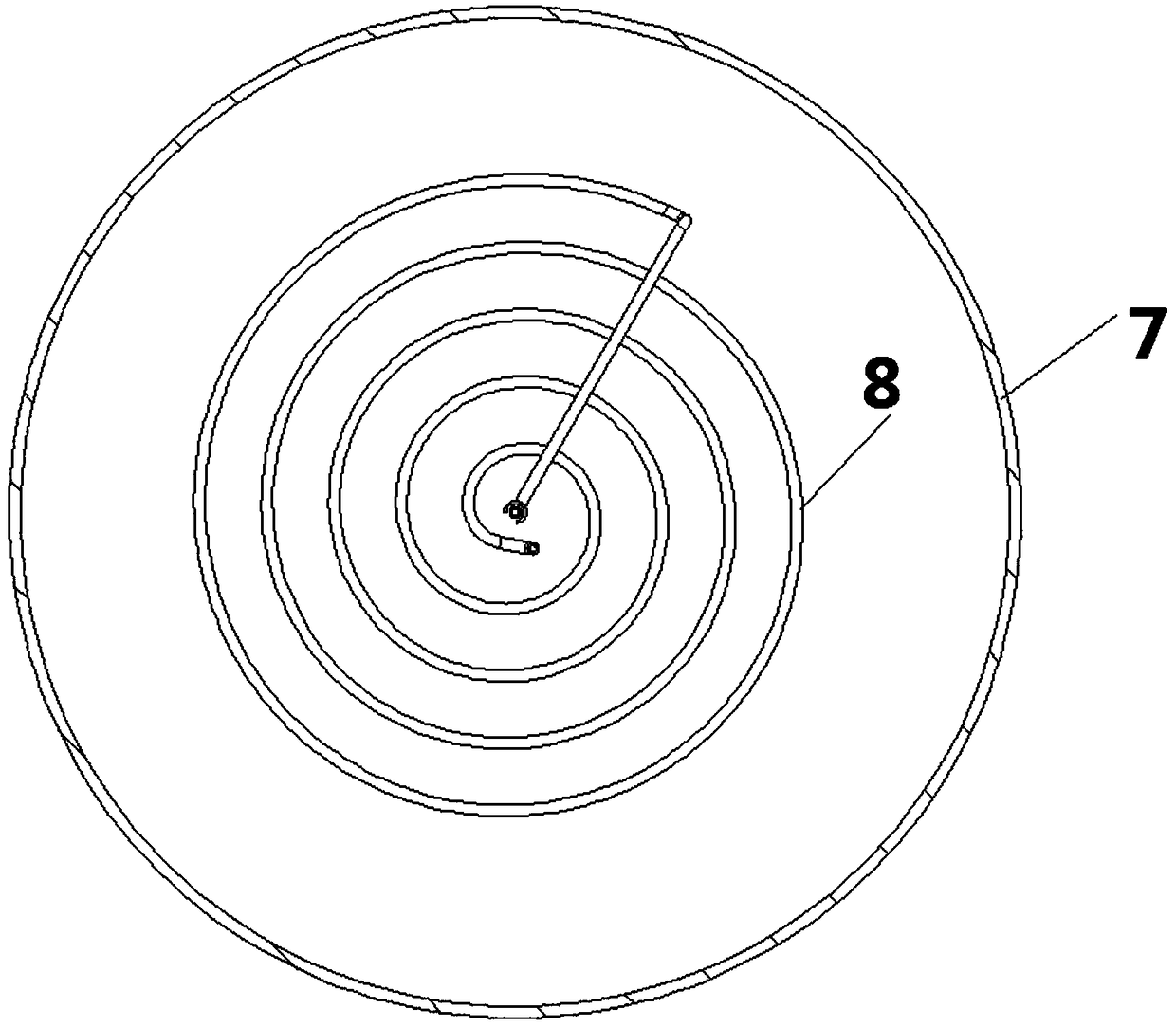

[0051] Such as figure 1 As shown, a solar loop heat pipe system for microbial soil purification includes a solar collector 1, a heat exchanger 3, and a fan 2. The heat exchanger 3 is connected to the solar collector 1, and the fan 2 inputs air To the heat exchanger 3, after being heated into hot gas in the heat exchanger 3, it enters the gas inlet channel 5 of the loop heat pipe device. The heat pipe is arranged in the soil for repairing the soil.

[0052] The invention uses solar energy to heat the original heat source, applies solar energy to the soil restoration fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com