Drawer-type double-sided electromagnetic heating system

A drawer-type, electromagnetic technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of small heating area, low utilization rate, and high electromagnetic radiation, so as to improve energy density and utilization rate. , the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be described in further detail below in conjunction with the drawings:

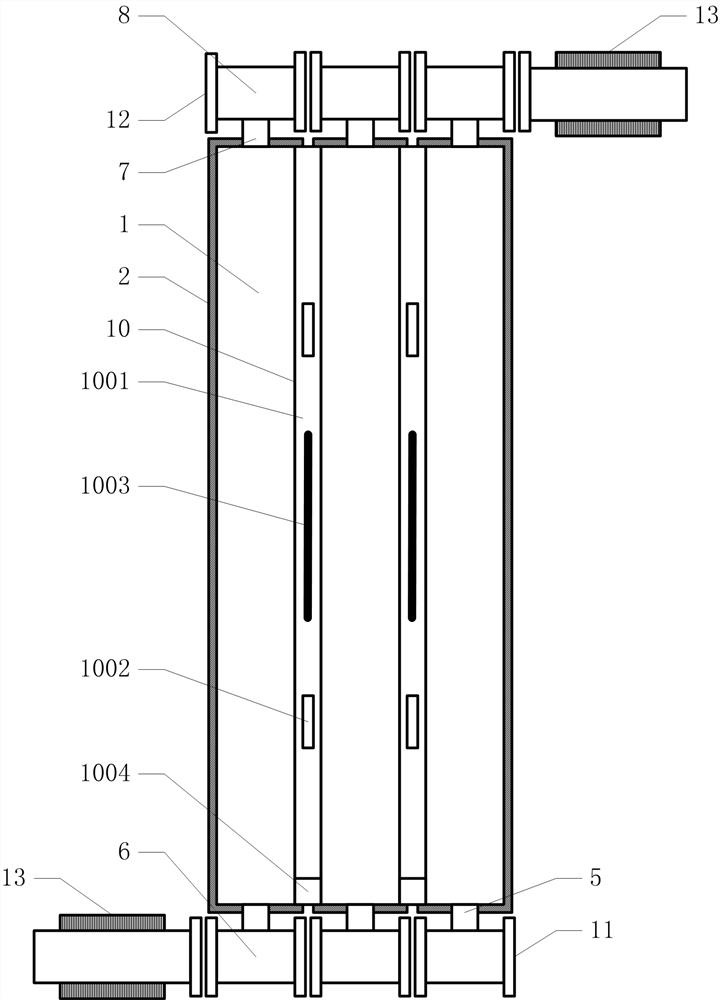

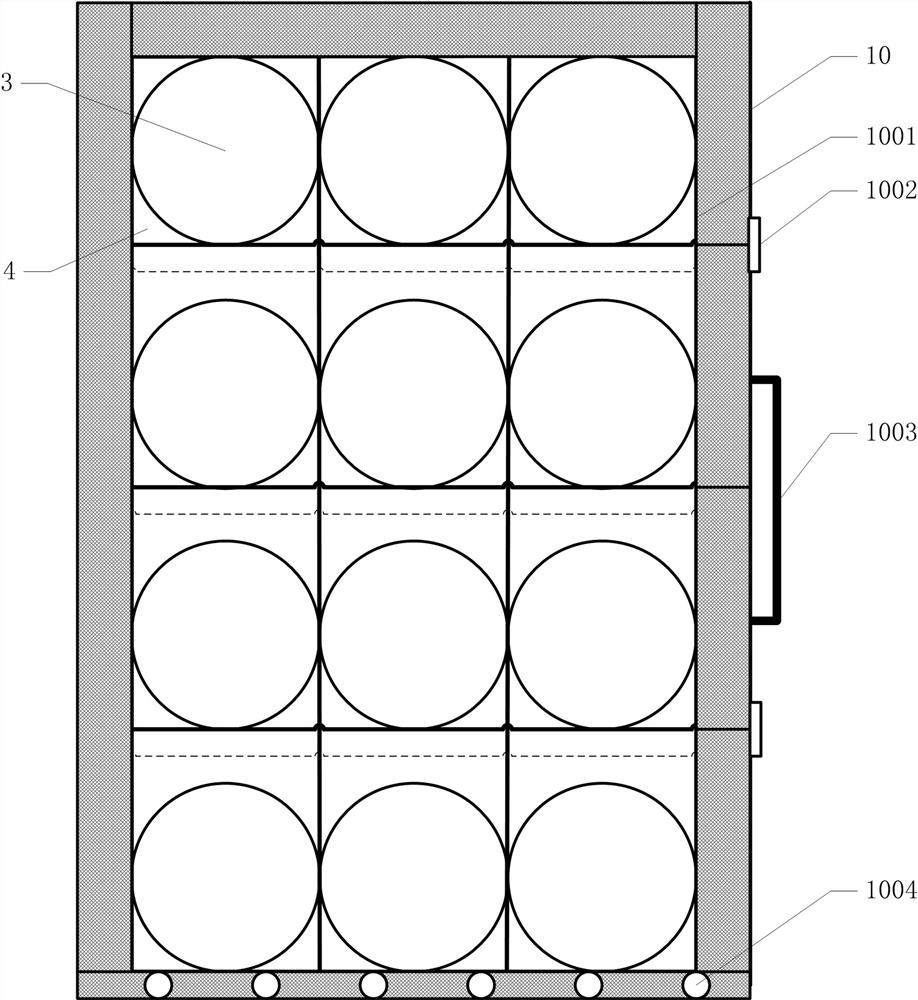

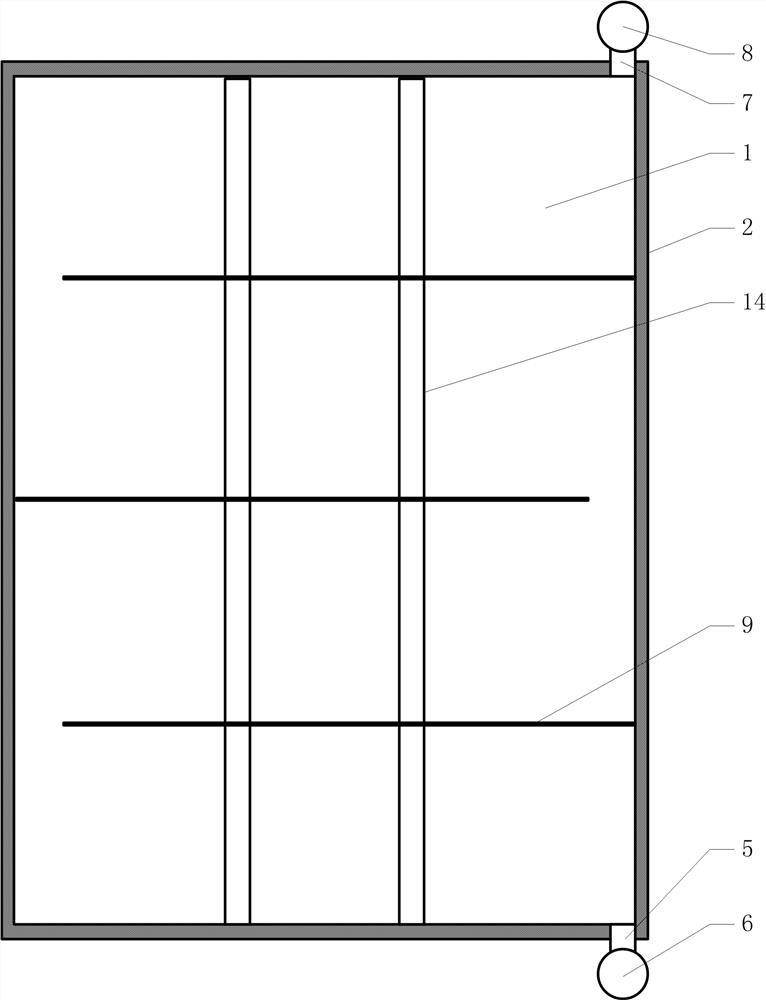

[0030]Such asfigure 1 Shown is the system front view of the drawer type double-sided electromagnetic heating system,figure 2 Shown is the side view of the drawer assembly. The drawer type double-sided electromagnetic heating system includes a heating water tank (1), an insulating layer (2), an electromagnetic coil (3), a coil seat (4), a water inlet (5), a water inlet pipe (6), Outlet (7), outlet pipe (8), partition (9), drawer type assembly (10), frame (1001), wiring socket (1002), handle (1003), guide rail (1004), inlet pipe method Lan (11), the flange (12) of the outlet pipe, the magnetizing coil (13) and the fixing column (14).

[0031]figure 1 There are three heating water tanks (1), and the exterior is covered with an insulation layer (2) to prevent internal heat loss; two adjacent heating water tanks (1) connect the water inlet pipe (6) through the water inlet pipe flange (11) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com