Self-rotating spraying device and washing machine

A spray device and self-rotating technology, applied in the field of washing machines, can solve the problems of unsatisfactory spray effect, weakened spray direction, weak spray water flow, etc., to achieve wide spray coverage, improve spray efficiency and effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

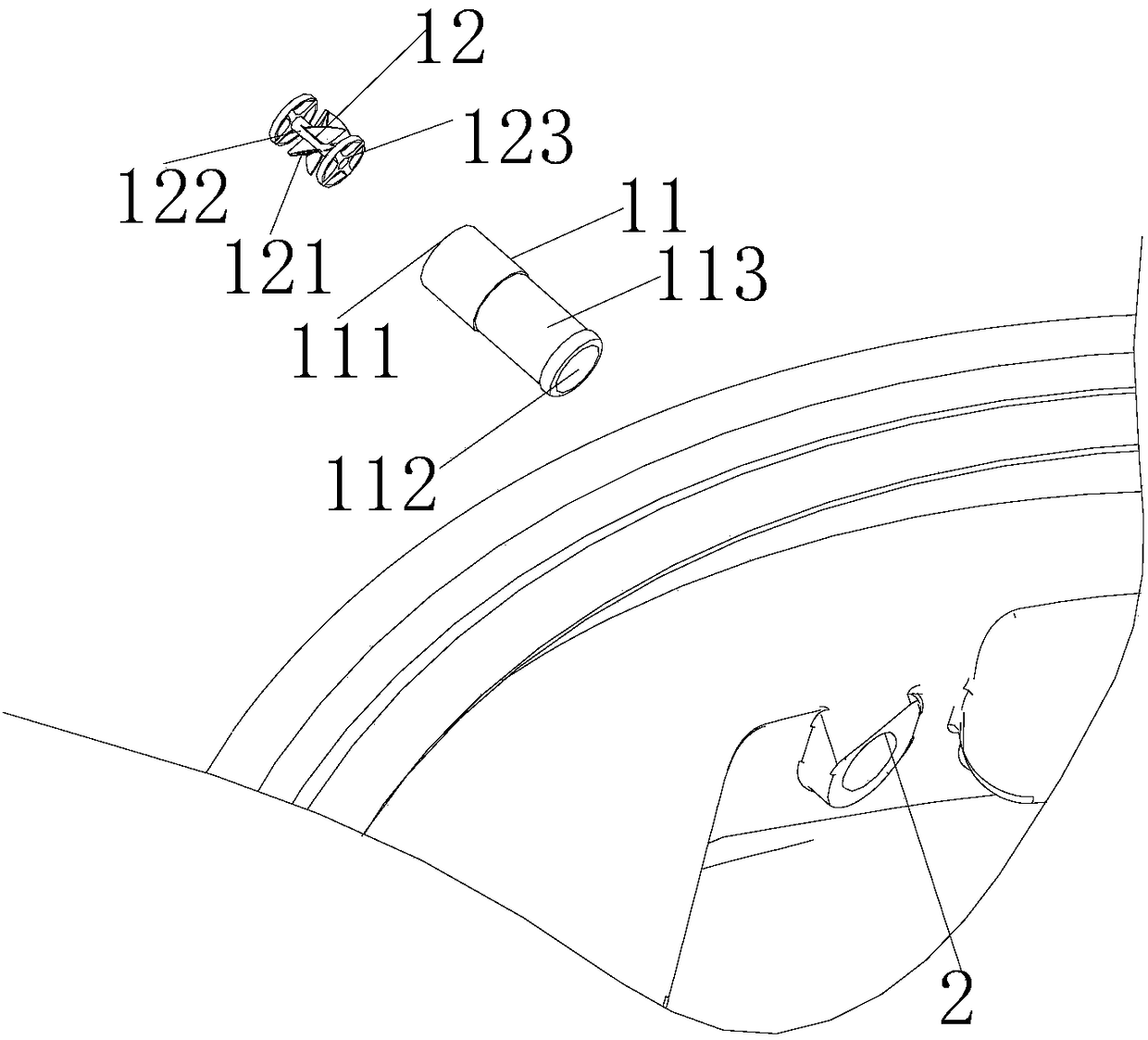

[0061] Such as Figure 1-7 As shown, in this embodiment, the self-rotating spray device 1 is arranged on the drum washing machine. In this embodiment, it is installed on the sealing window gasket 3 of the drum washing machine, and the sealing window gasket 3 has an air inlet 4. It is convenient for the air supply of the drying system. Of course, there is no such structure on the sealing window gasket 3 of the non-drying type drum washing machine. At least one installation hole 2 is provided on the sealing window gasket 3 , and the self-rotating spray device 1 is detachably arranged in the installation hole 2 .

[0062] The self-rotating shower device 1 includes

[0063] Spray head 11, in which a through hole for water flow is set, one end of the through hole is a water inlet 111, and the other end is a water outlet 112, and the water inlet 111 is connected to a water inlet pipeline;

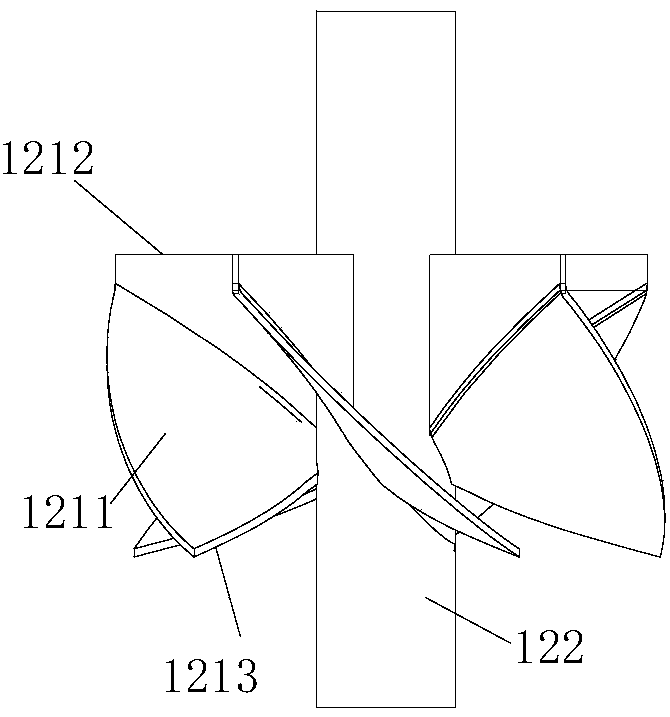

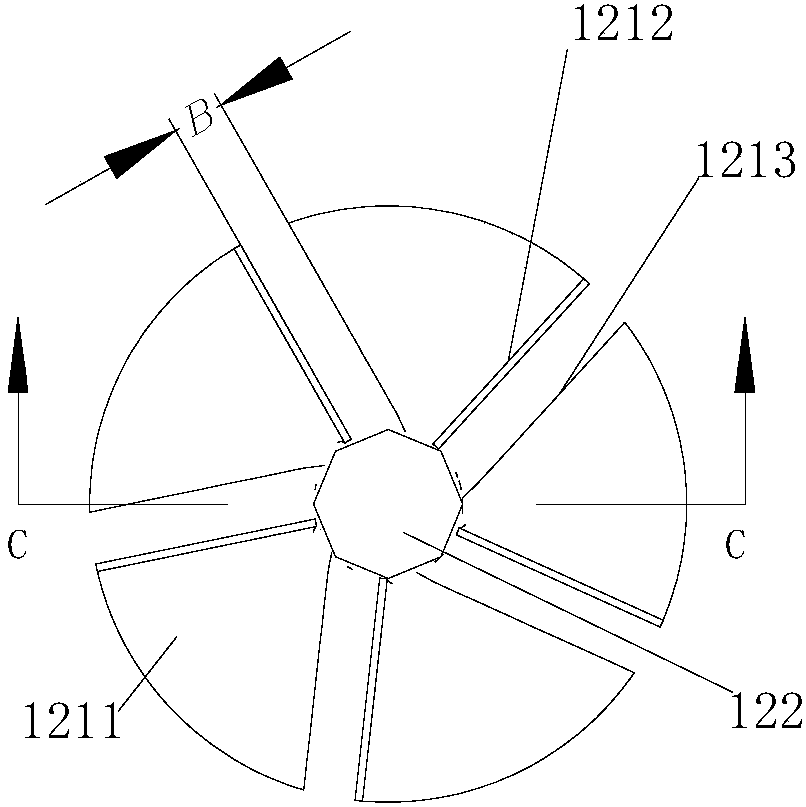

[0064] The self-rotating assembly 12, the self-rotating assembly 12 is arranged in the thro...

Embodiment 2

[0075] Such as Figure 1-Figure 7 As shown, in this embodiment, the self-rotating spray device 1 is arranged on the drum washing machine. In this embodiment, it is installed on the sealing window gasket 3 of the drum washing machine, and the sealing window gasket 3 has an air inlet 4. It is convenient for the air supply of the drying system. Of course, the sealing window gasket 3 of the non-drying type drum washing machine does not have this structure. At least one installation hole 2 is provided on the sealing window gasket 3 , and the self-rotating spray device 1 is detachably arranged in the installation hole 2 .

[0076] The self-rotating shower device 1 includes

[0077] Spray head 11, in which a through hole for water flow is set, one end of the through hole is a water inlet 111, and the other end is a water outlet 112, and the water inlet 111 is connected to a water inlet pipeline;

[0078]The self-rotating assembly 12, the self-rotating assembly 12 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com