a sewing machine

A sewing machine and backstitching technology, applied to sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of high processing cost, complex structure, redundant transmission chain of the overall structure, etc., to reduce processing cost, simplify the transmission chain, Effects of simplified part design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

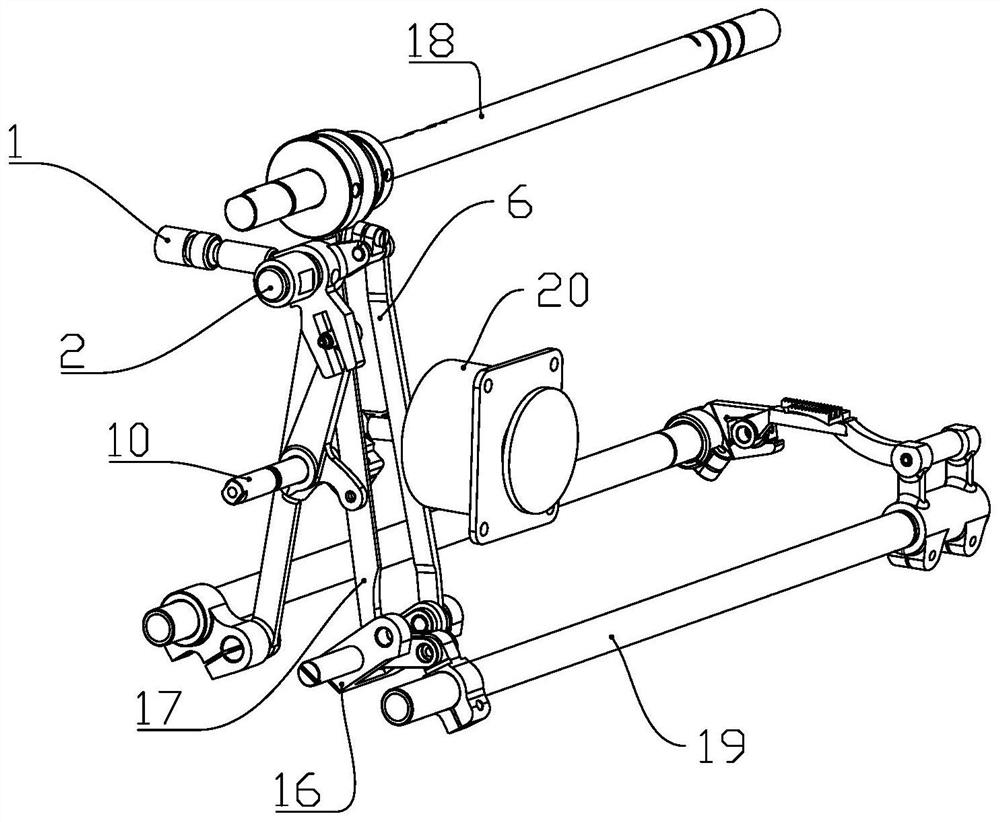

[0035] The present invention will be further described below with specific embodiment, see Figure 5-15 :

[0036] A sewing machine, comprising a stitch length adjusting stud 21, an adjuster shaft 22, and a stitch length adjuster 23 fixed on the adjuster shaft 22, which is swingably arranged on the bottom plate (in the figure) by a first positioning pin 24 and a second positioning pin 25 Not shown) on the swing seat 26. The adjusting stud 21 is installed in the casing (not shown in the figure) through threaded rotation, and is used for limiting the needle length adjuster 23 . The adjuster shaft 22 is rotatably arranged in the casing, and the stitch length adjuster 23 is fixedly connected with the adjuster shaft 22 and can rotate synchronously with the adjuster shaft 22 . The upper end of the reverse feeding connecting rod 27 is connected on the stitch regulator 23, and the lower end of the reverse feeding connecting rod 27 is connected on the swing seat 26, and the swing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com