A kind of high-yield compound organic fertilizer and its production process

An organic fertilizer and production process technology, which is applied in the field of high-yield compound organic fertilizer and its production process, can solve the problems of poor fermentation efficiency, high-temperature-resistant bacteria, and insect eggs that cannot be removed, so as to reduce crop diseases, improve efficacy, and improve fermentation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A kind of production technology of high-yield compound organic fertilizer, it comprises the following steps:

[0052] Step 1: Select animal manure or straw as the raw material of organic fertilizer;

[0053] Step 2: pretreating the organic fertilizer raw materials selected in step 1 through a pretreatment device;

[0054] Step 3: Fermenting the pretreated organic fertilizer raw materials to obtain fermented and decomposed materials;

[0055] Step 4: Dry the fermented and decomposed material through a drying device;

[0056] Step 5: crushing the dried organic fertilizer through a crushing device;

[0057] Step 6: Granulate the crushed organic fertilizer through a granulator, and then pack it into bags;

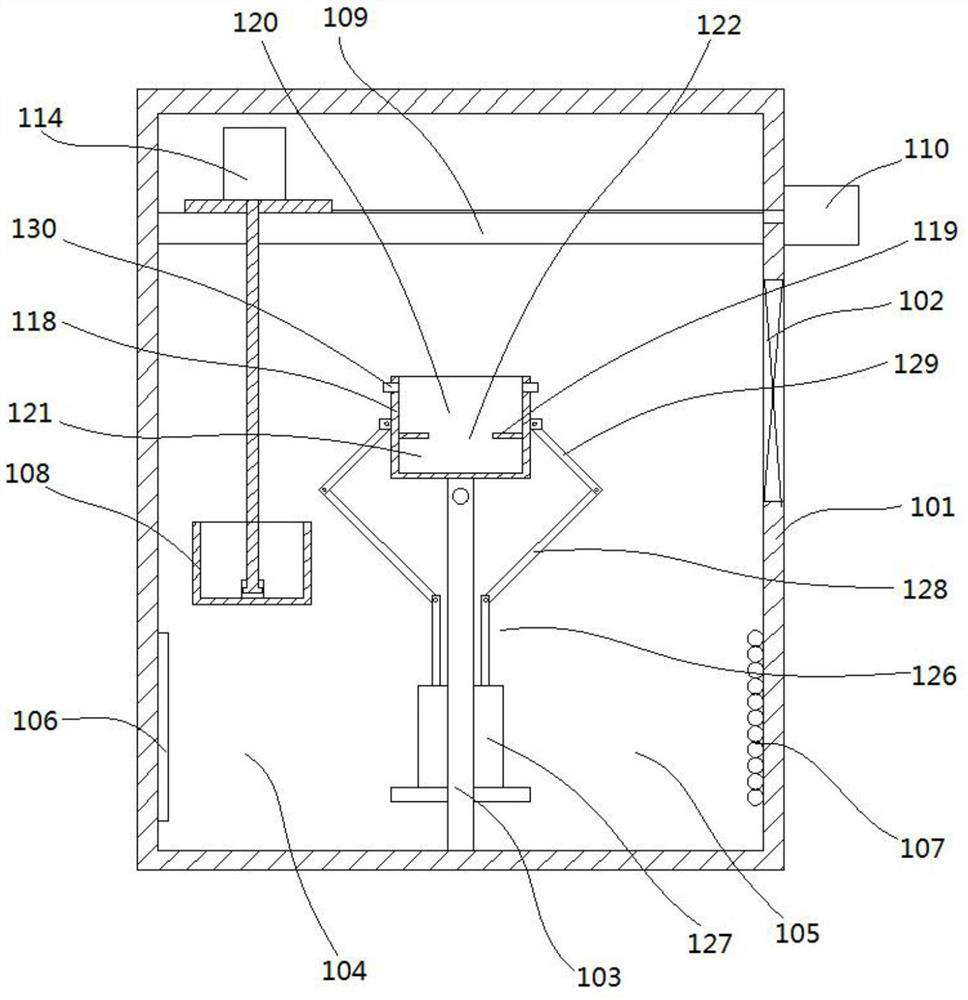

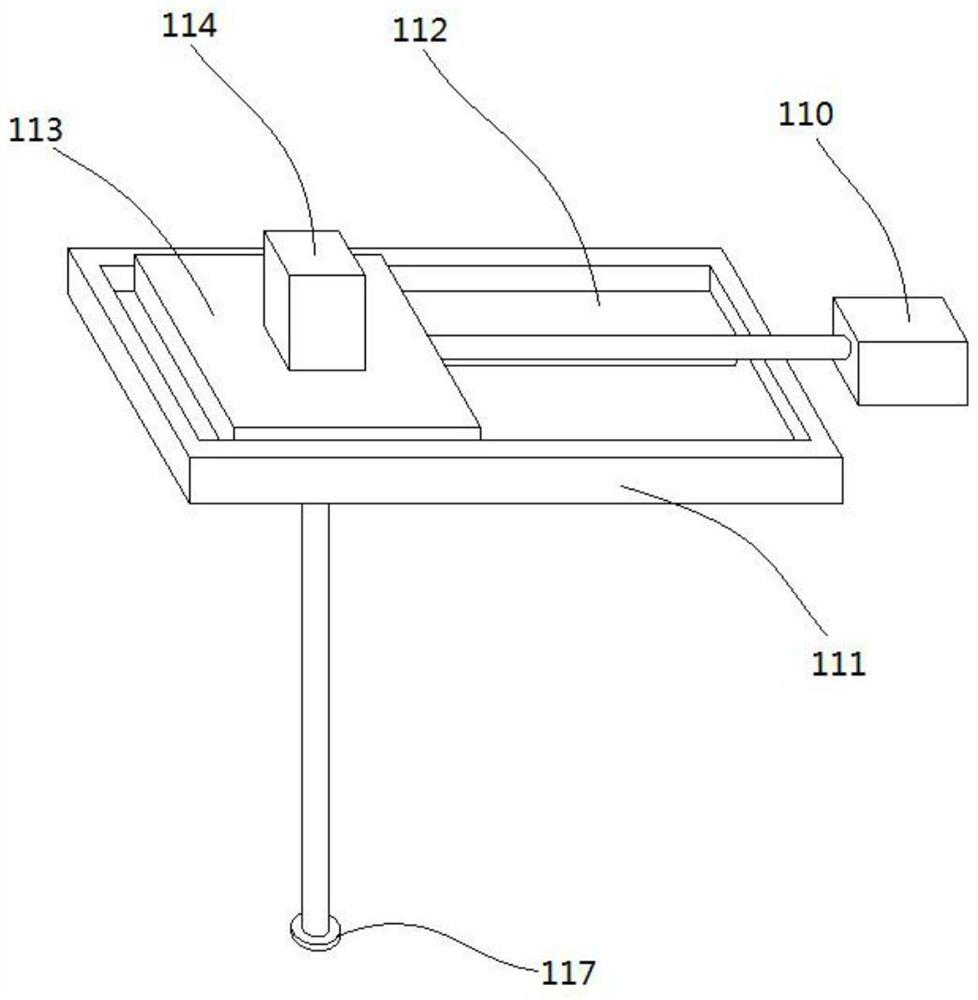

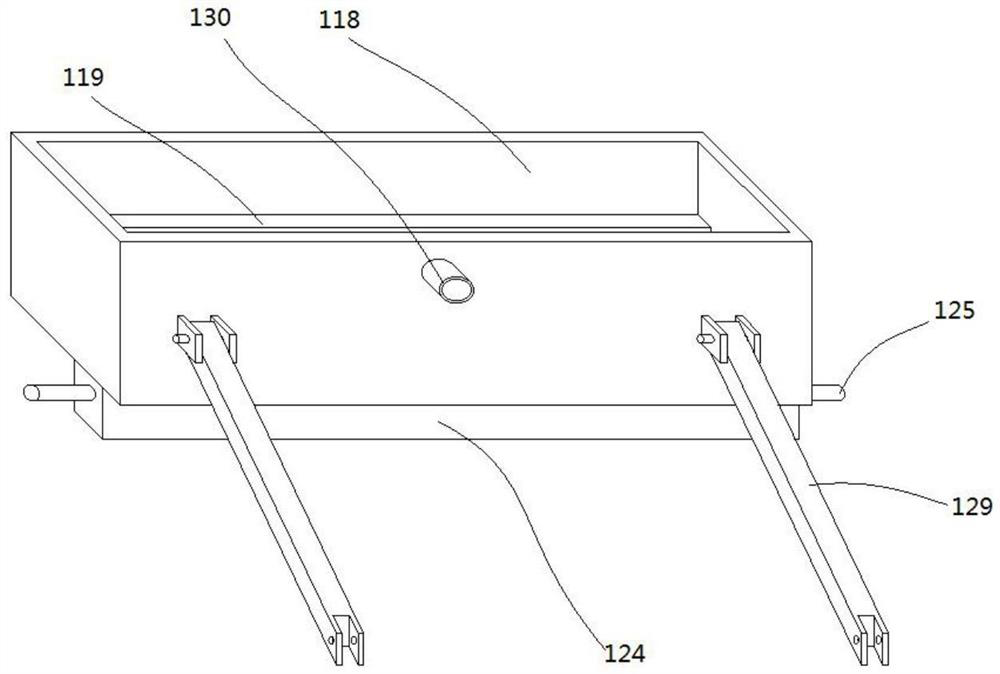

[0058] Such as Figure 1-Figure 7 As shown, wherein the pretreatment device in step 2 includes a cuboid pretreatment housing 101, the right side wall of the pretreatment housing 101 is provided with a feed door 102, and a vertical The partition plate 103 on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com