Surface treatment method of glass products and glass products

A technology for glass products and surface treatment, applied in coatings and other directions, can solve the problems of products lacking texture and three-dimensional sense, no color changes and layers, and inability to meet consumers, achieving good safety and environmental performance, practicability and adaptability Strong, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

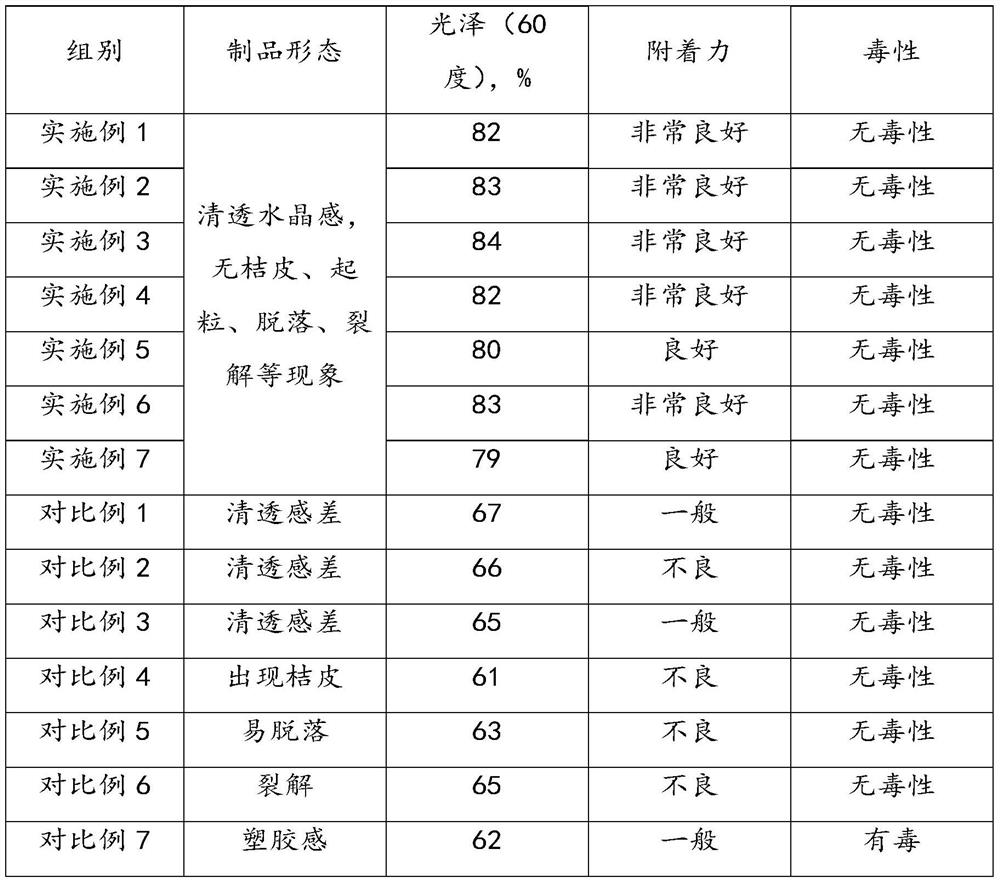

Examples

preparation example Construction

[0044] The preparation method of the texture slurry described in the present invention can adopt a conventional mixing and compounding process, conventional technical means in the field, specifically as follows:

[0045] Weigh the isopropanol, propylene glycol methyl ether acetate and nano silicon dioxide according to the formula ratio, mix and stir evenly.

[0046] In a preferred embodiment, the glass product after surface cleaning is painted by means of spray coating, roller coating or flow coating, preferably by means of spray coating.

[0047] Preferably, spraying is carried out at normal temperature and pressure, and the air pressure and flow rate of spraying can be adjusted according to demand;

[0048] Preferably, the air pressure for spraying is 100-300kPa;

[0049] And / or, the flow rate of spraying is 20-60CC / min, preferably 30-50CC / min; the flow rate is generally small flow rate or medium flow rate, and the flow rate can generally be adjusted according to the size o...

Embodiment 1

[0068] A surface treatment method for glass products, comprising the following steps: surface cleaning, coloring and drying;

[0069] Among them, the raw materials used in the coloring process include color paste and texture paste, and the texture paste includes the following components by weight percentage:

[0070] Isopropyl Alcohol 24%, Propylene Glycol Methyl Ether Acetate 58% and Nano Silica 18%.

Embodiment 2

[0072] A surface treatment method for glass products, comprising the following steps: surface cleaning, coloring and drying;

[0073] Among them, the raw materials used in the coloring process include color paste and texture paste, and the texture paste includes the following components by weight percentage:

[0074] Isopropyl Alcohol 24%, Propylene Glycol Methyl Ether Acetate 64% and Nano Silica 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com