Plate conveying platform and plate conveying system

A conveying platform and conveying system technology, applied in the field of conveying platform, can solve the problems of increasing the degree of deformation, the skew of the circuit board, the falling of the circuit board, etc., and achieve the effect of reducing the deformation amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

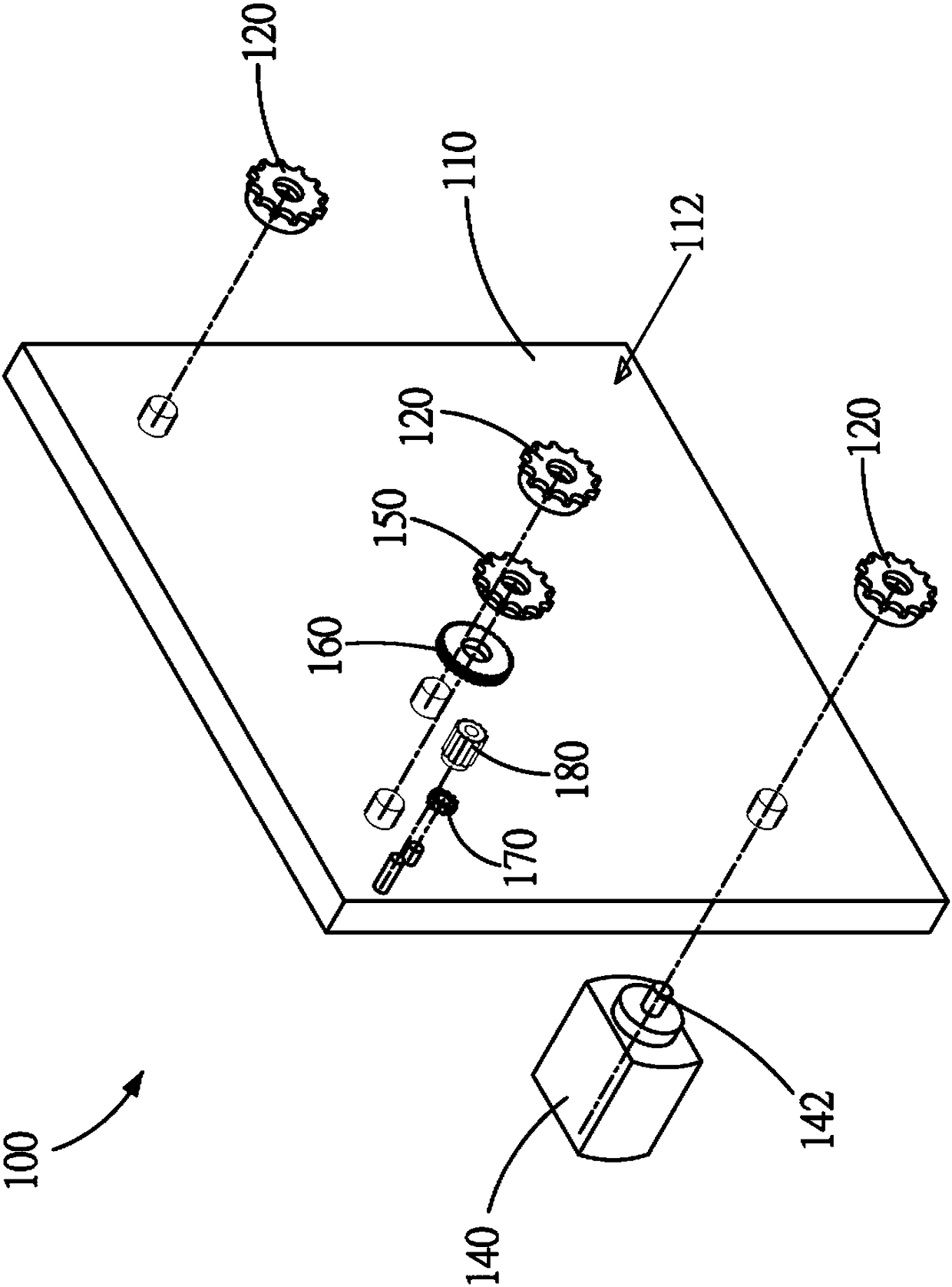

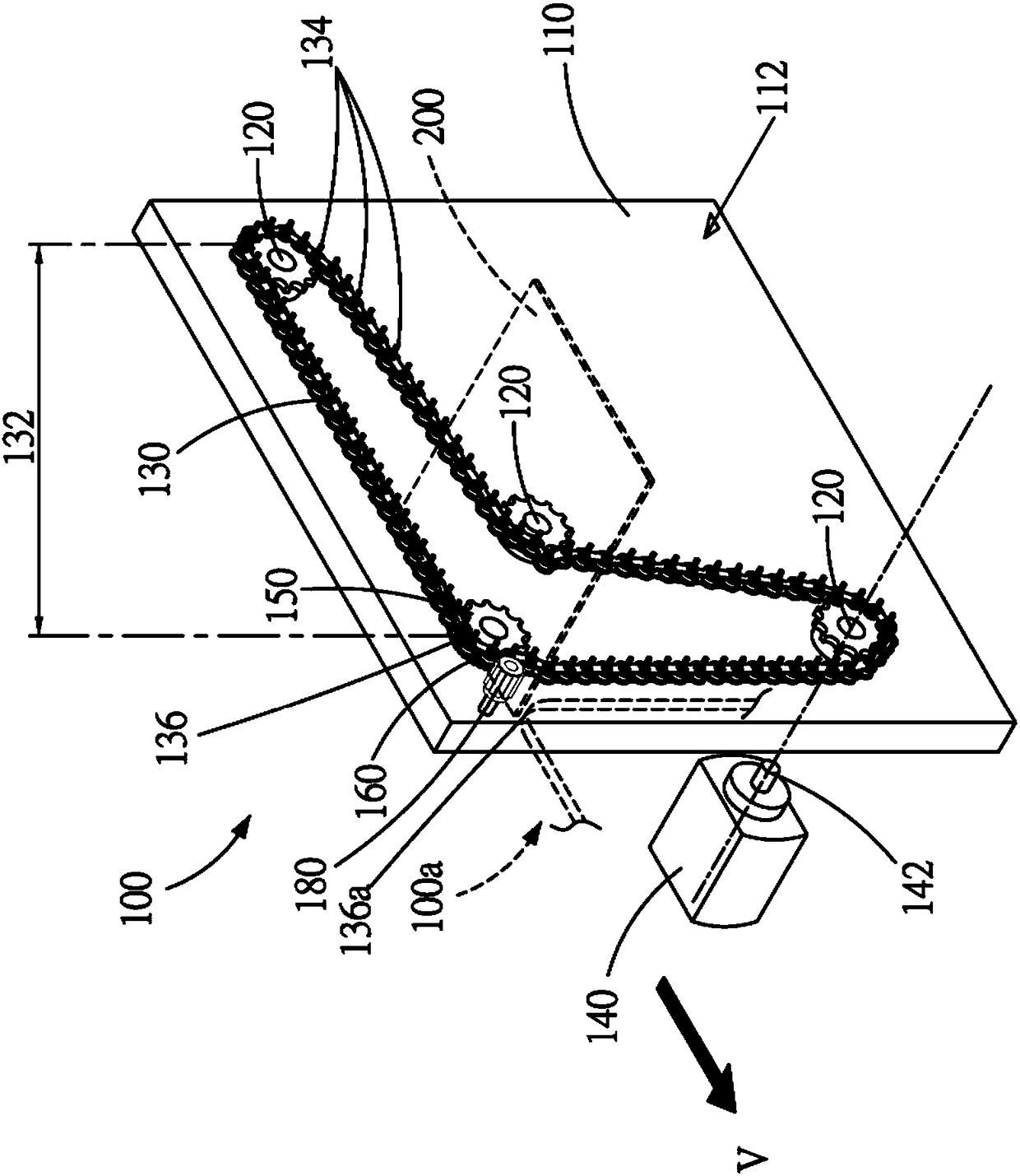

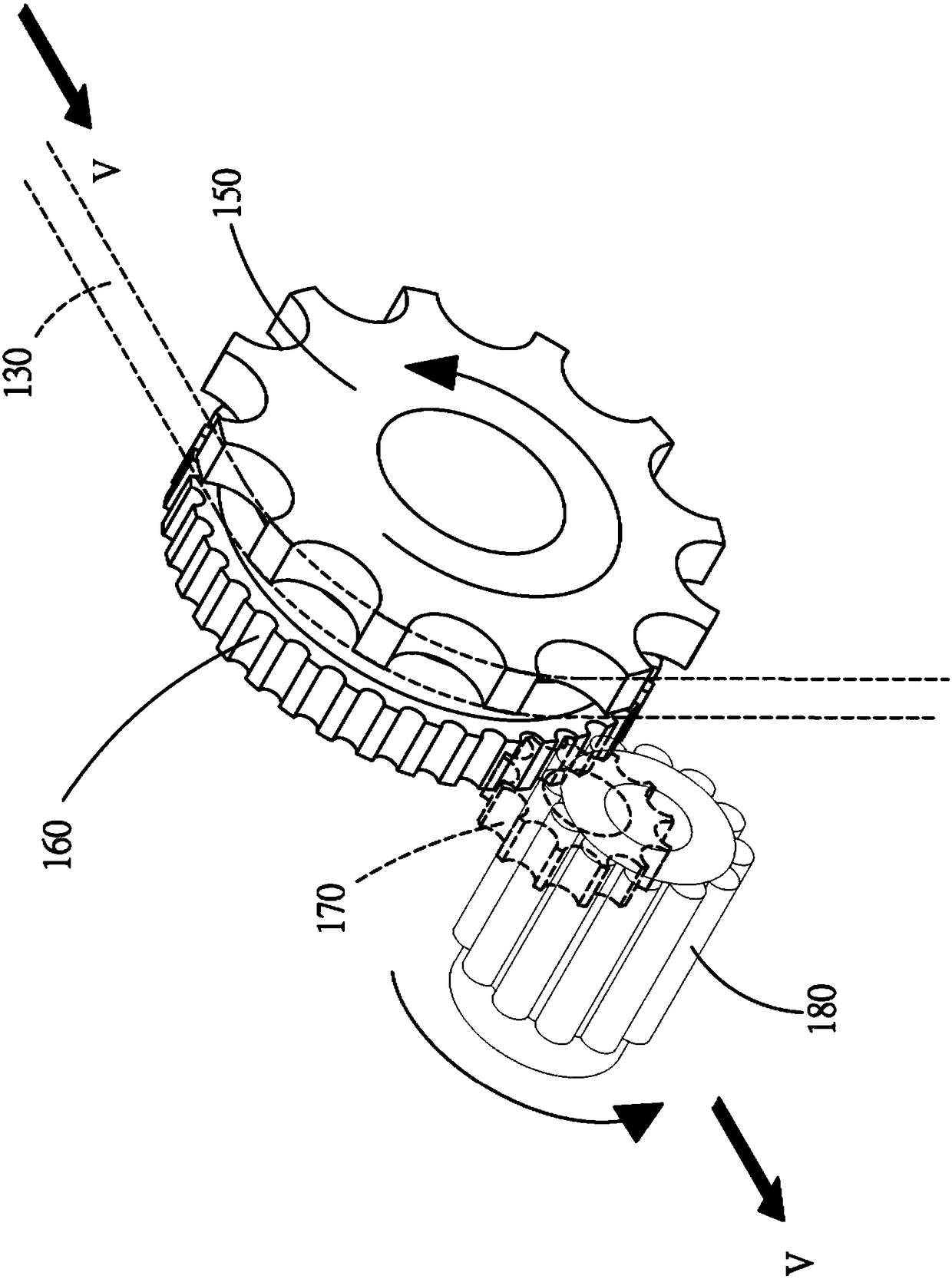

[0062] see figure 1 , figure 2 as well as image 3 As shown, it is a plate conveying platform 100 provided by the first embodiment of the present invention, which is used to carry the plate 200, and move the plate 200 toward a conveying direction V, and convey the plate 200 to another conveying platform 100a.

[0063] The plate conveying platform 100 includes a base 110, several transmission coupling wheels 120, a flexible closed-loop transmission member 130, a motor 140, a driven coupling wheel 150, a driven gear 160, and a relay gear 170 and a driving gear 180 .

[0064] The base 110 is used to provide an installation surface 112 upright on the ground for other components to be installed on the installation surface 112 , and make the rotation axis of each component perpendicular to the installation surface 112 and parallel to the ground. The base 110 can be a flat plate erected on the ground, or a frame erected upright. In the first embodiment, an upright flat plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com