Underbody Structures for Dual Track Vehicles

A technology of bottom structure and double-track vehicles, which is applied to vehicle components, superstructures, superstructure subassemblies, etc., and can solve problems such as tool channel obstruction and coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

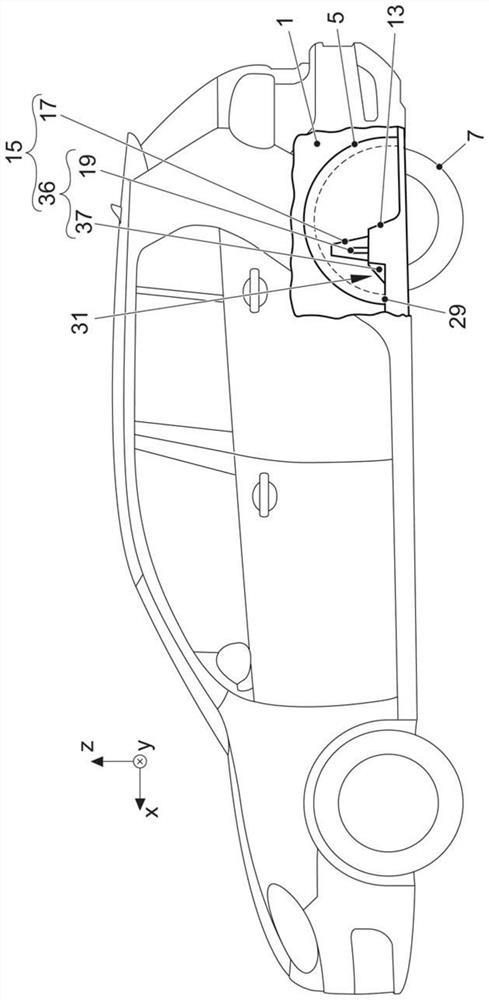

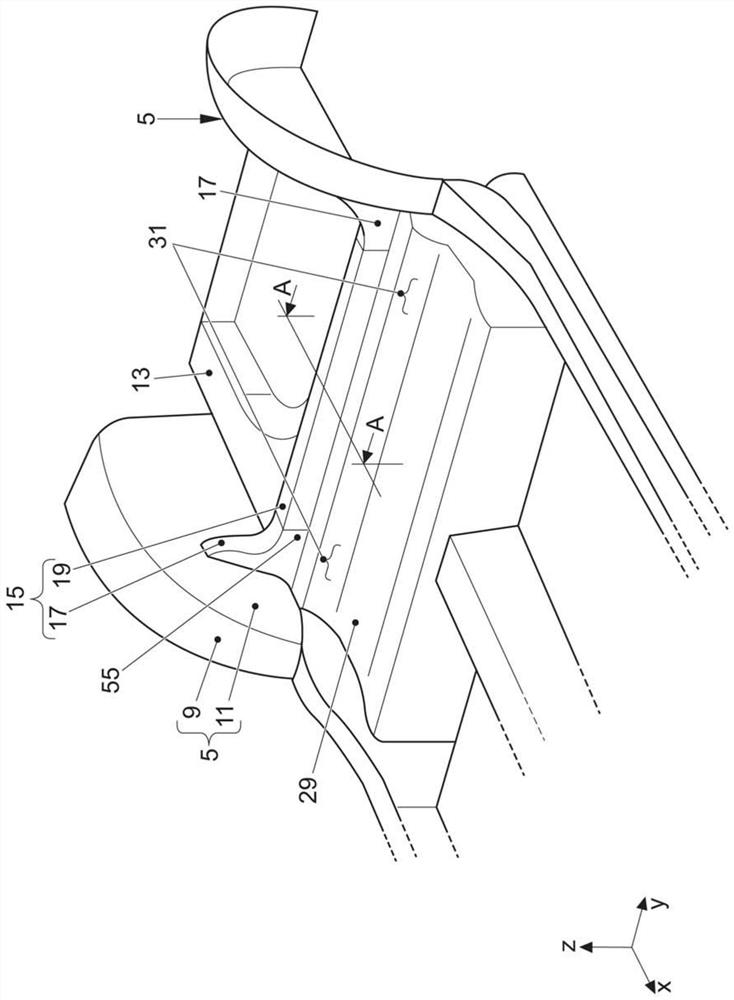

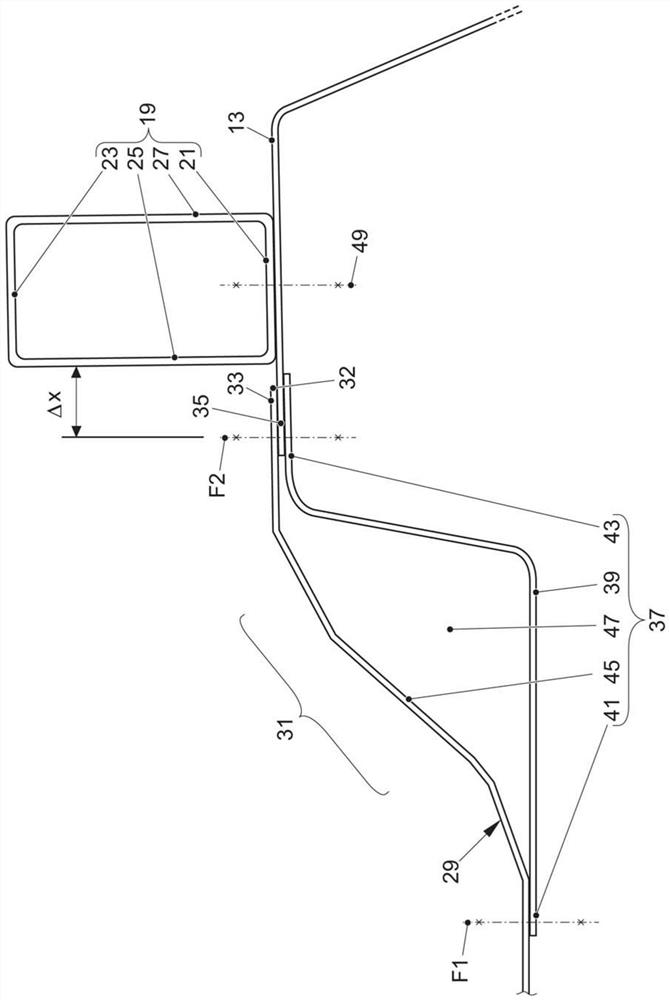

[0026] exist figure 1 Figure 2 shows an underbody structure for the rear side of a vehicle, wherein the storage space 1 on the rear side is delimited by a rear floor part 13 and outwards in the vehicle transverse direction y by a rear wheel housing 7 in each case, wherein, exist figure 1 Only the wheel house panel 5 is shown. exist figure 2 Here, the wheel house panel 5 has a peripheral wall 9 extending at intervals around the rear wheel 7 and transitioning inwards in the vehicle transverse direction y to a vertical side wall 11 of the vehicle interior. The side wall 11 is connected on the bottom side to the rear floor part 13 , for example by solder joints. like figure 2 It is further shown that the inner corner region between the side walls 11 of the wheel house panel 5 and the rear floor part 13 is reinforced with wheel house cross member reinforcements 15 .

[0027] exist figure 2 The wheel house cross member reinforcement 15 has, on the wheel house side, a shell-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com