Method for manufacturing single layered body or laminated body

A manufacturing method and laminated body technology, applied to chemical instruments and methods, lamination, layered products, etc., can solve the problems of equipment cost, installation space, and unsuitable production, so as to achieve high operating efficiency and high-speed manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0193] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, although the manufacturing example of a laminated body is demonstrated below, it can demonstrate similarly about a single-layer body.

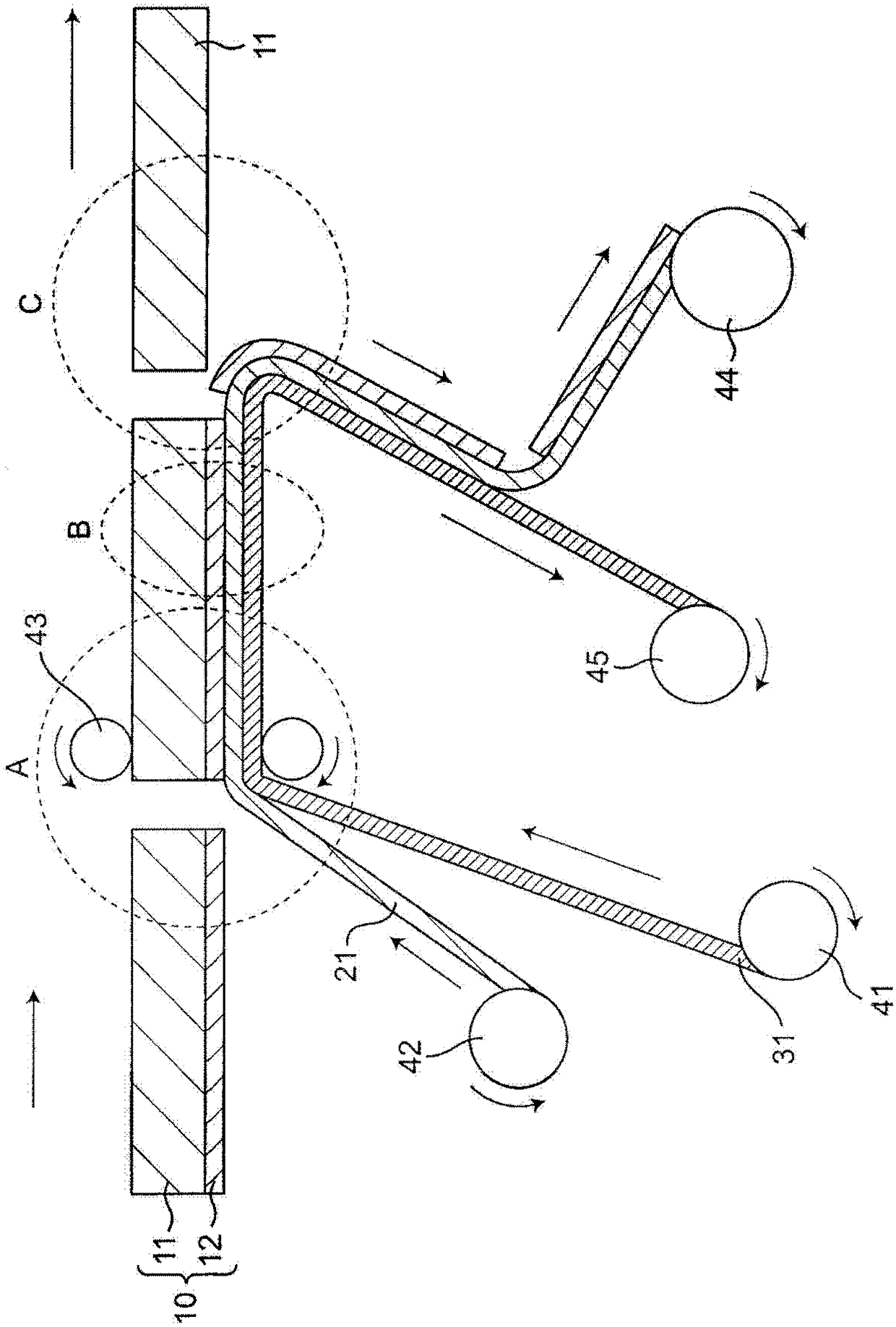

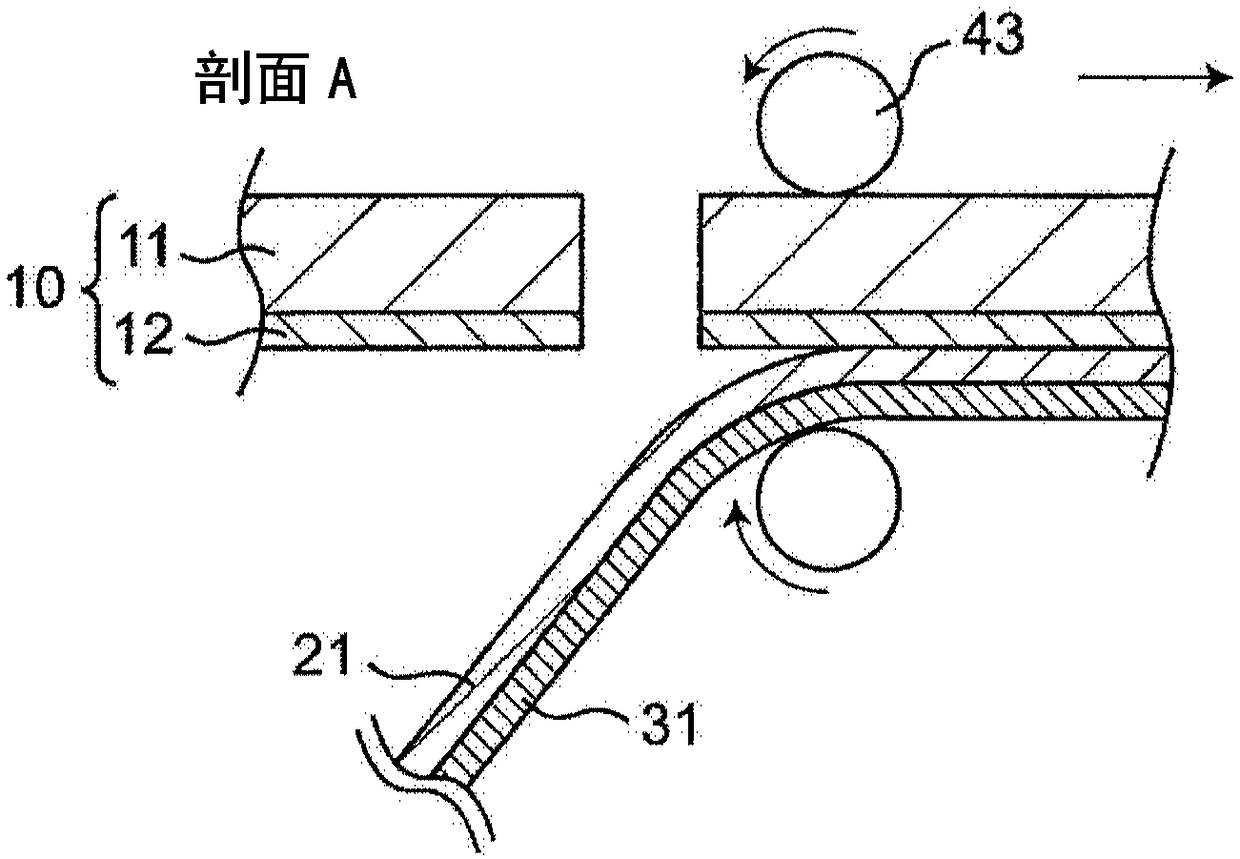

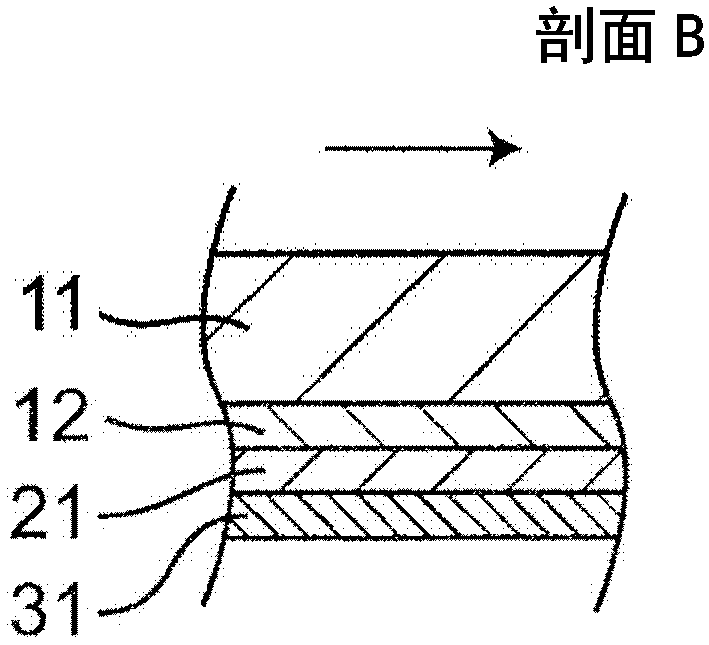

[0194] For example, figure 1 It is an overall side view showing the outline of the manufacturing method of the present invention. In more detail, figure 1 A method for producing a laminate using a laminate cut to a predetermined size is exemplified.

[0195] exist figure 1 Among them, the laminated body 10 with a separator includes a laminated body 11 and a separator 12 cut to a predetermined size. The laminated body 10 with the diaphragm is from figure 1 From the left, for example, it is conveyed on a conveyor belt (not shown). The elongated adhesive member 21 sent out from the unwinding roller 42 of the adhesive member and the elongated peeling member 31 sent out from the unwinding roller 41 of the peeling member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com