Plate shearing sliding groove type robot griper

A robot hand and chute technology, applied in the directions of manipulators, accessories of shearing machines, shearing devices, etc., can solve the problems of parallel clamping, easy clamping of thin plates, strong clamping pressure, etc., and achieve the cylinder action direction and The effect of vertical clamping, flat gripper structure, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

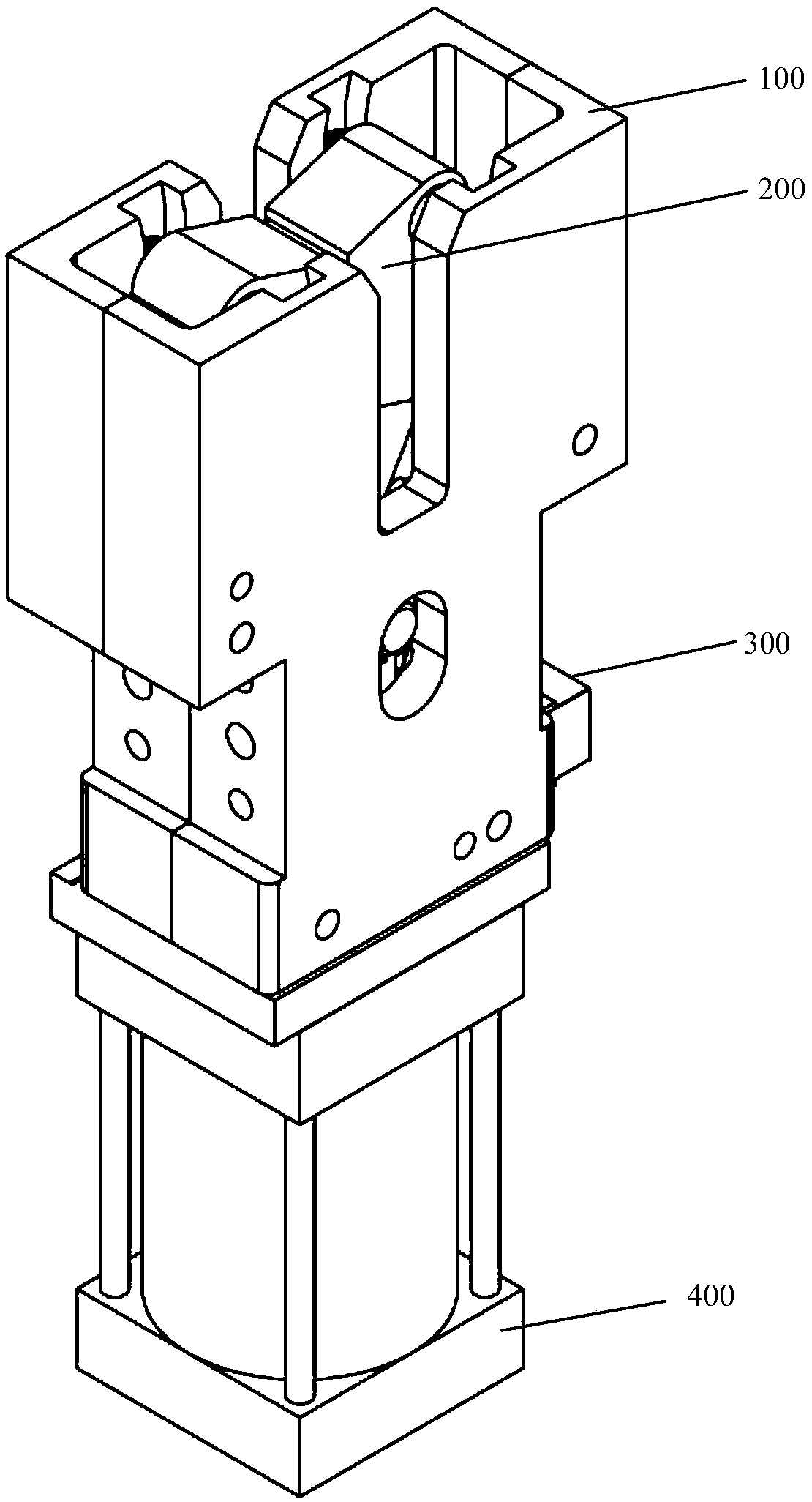

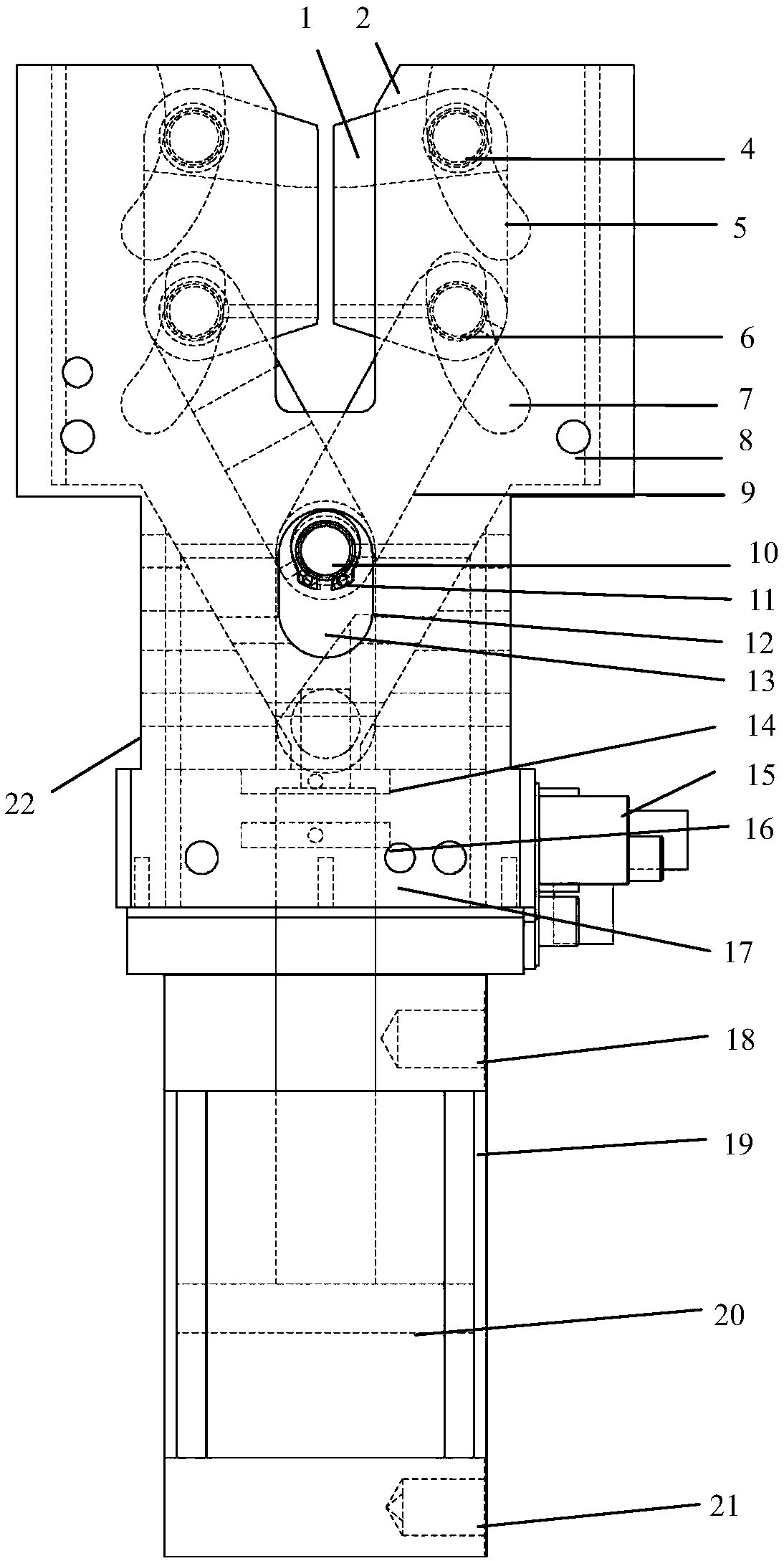

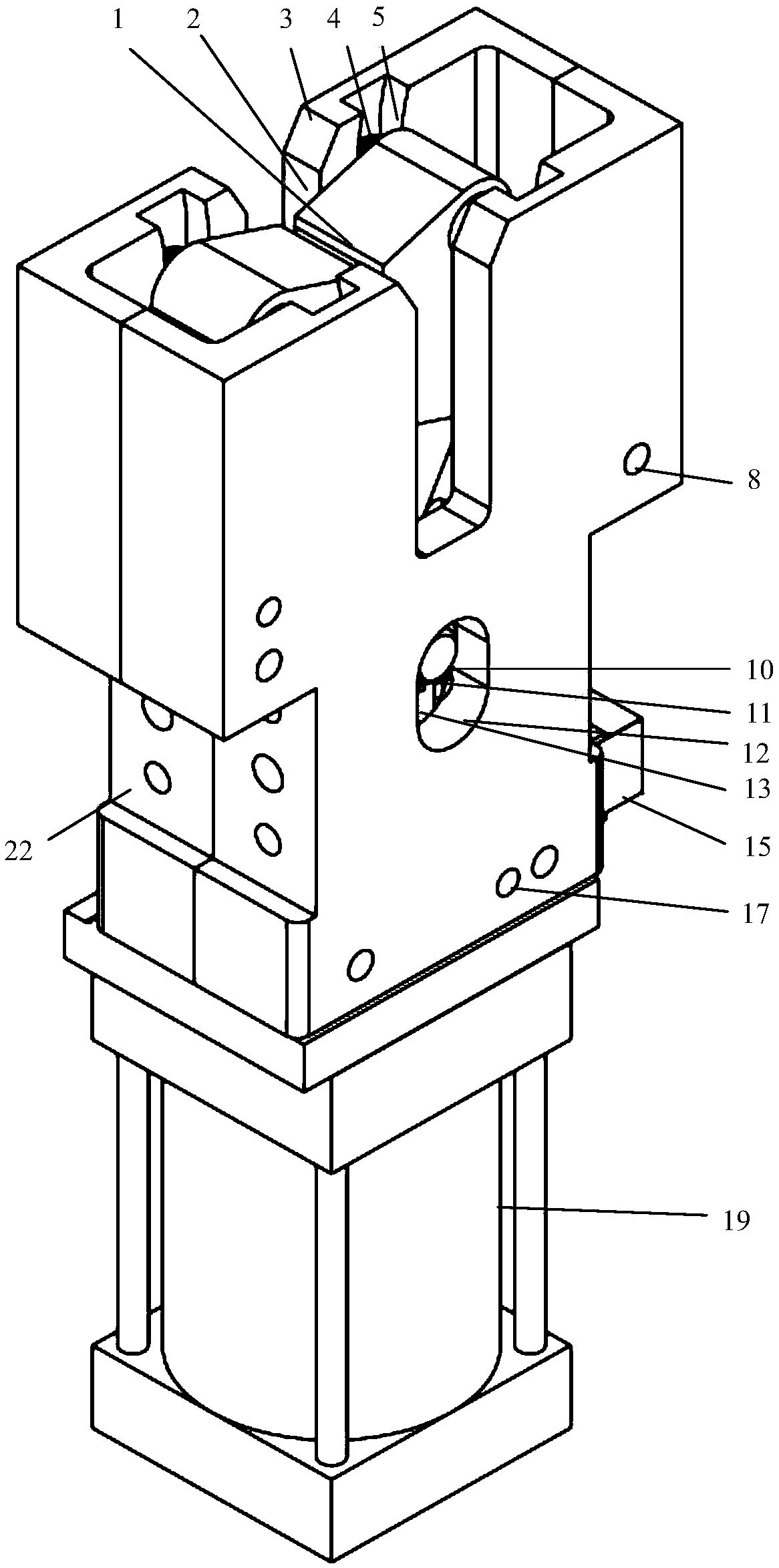

[0025] Such as Figure 1 ~ Figure 3 As shown, this embodiment provides a chute-type robotic gripper for shearing plates, including a housing 100, a chute-type clamping module 200, a position sensing module 300 and a driving module 400, and the housing 100 is provided with interconnected The chute-type clamping module 200 and the position sensing module 300 are connected to the driving module 400 at the lower end of the casing 100 .

[0026] The upper end of the housing 100 is a symmetrical clamping structure, and is provided with an arc-shaped chute and a middle chute 12. The arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com