Pressure-casting die

A technology of die-casting molds and beams, which is applied in the field of aluminum alloy die-casting mold structures, can solve problems such as product bending deformation, bending deformation, and difficulty in simultaneously forming lateral forming holes and radial blind holes on the inner wall of the lateral forming holes, etc., to achieve Avoid the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

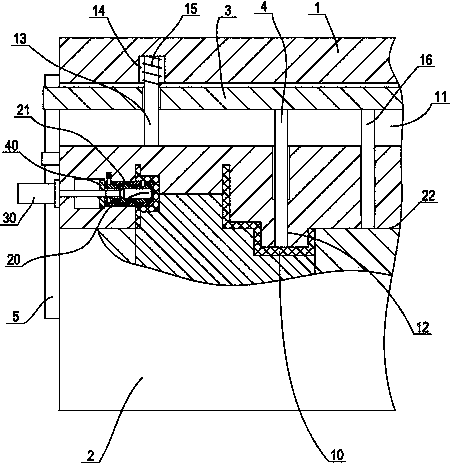

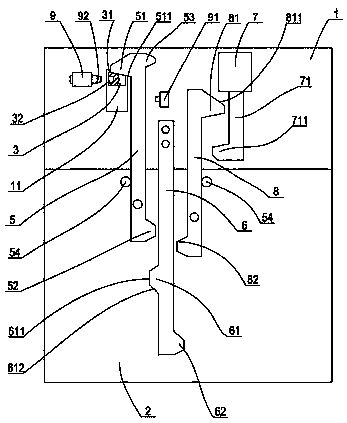

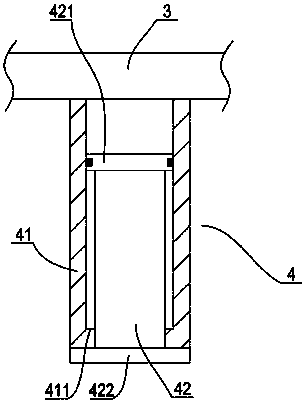

[0020] Such as figure 1 , figure 2 As shown, a die-casting mold is suitable for products with openings or cavities facing the upper and lower sides at the same time, or products with relatively close molding forces on the upper and lower sides of the parting surface, specifically including products with a pouring system Upper die 1, lower die 2 with ejection mechanism. For the sake of explanation, we refer to the mold splitting and mold closing directions of the upper and lower molds as the longitudinal direction of the die-casting mold, and correspondingly, the direction perpendicular to the longitudinal direction is called the transverse direction of the die-casting mold. Firstly, a long groove 11 arranged horizontally through the left and right sides is set in the upper mold. The cross section of the long groove is rectangular. The guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com