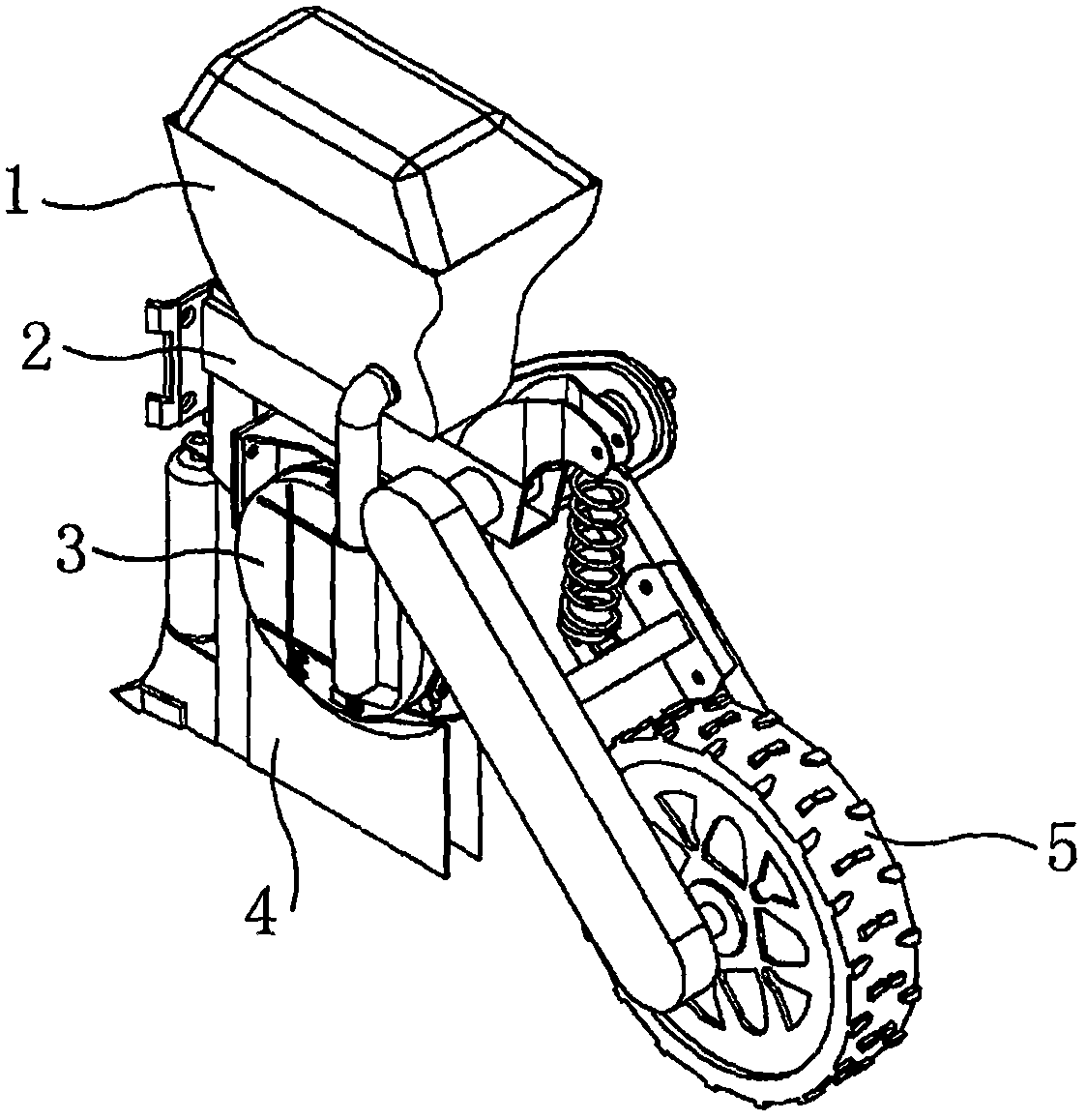

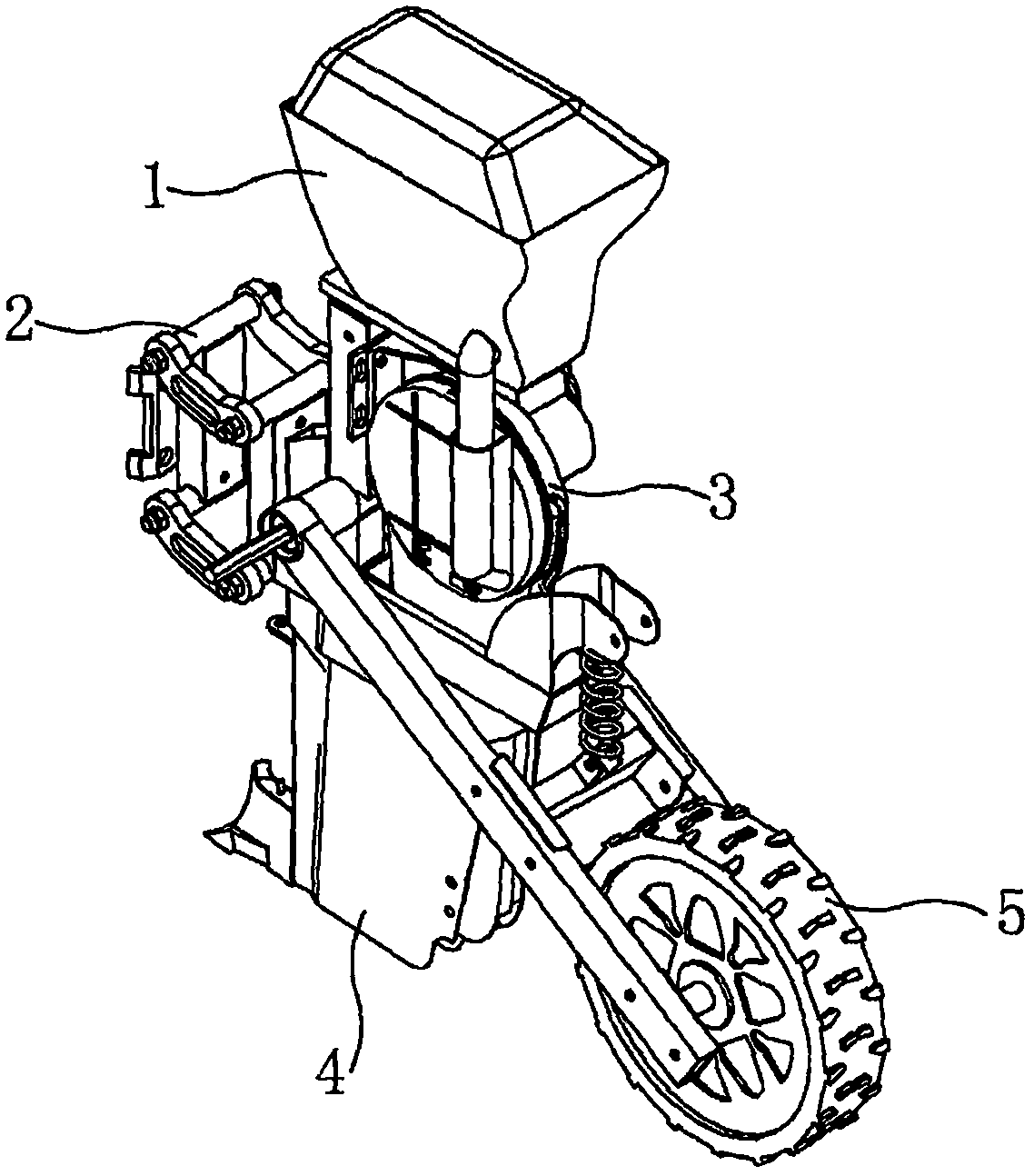

Seed metering device capable of conveying seeds forward

A seed metering and forward feeding technology, which is applied to the parts of the seeder and the machinery of interval-type quantitative seeding, etc., can solve the problems of increasing the probability of damage to the seed metering device, the low installation position of the seed metering device, and the low work efficiency. The effect of reducing seed breakage rate, accurate seed placement, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

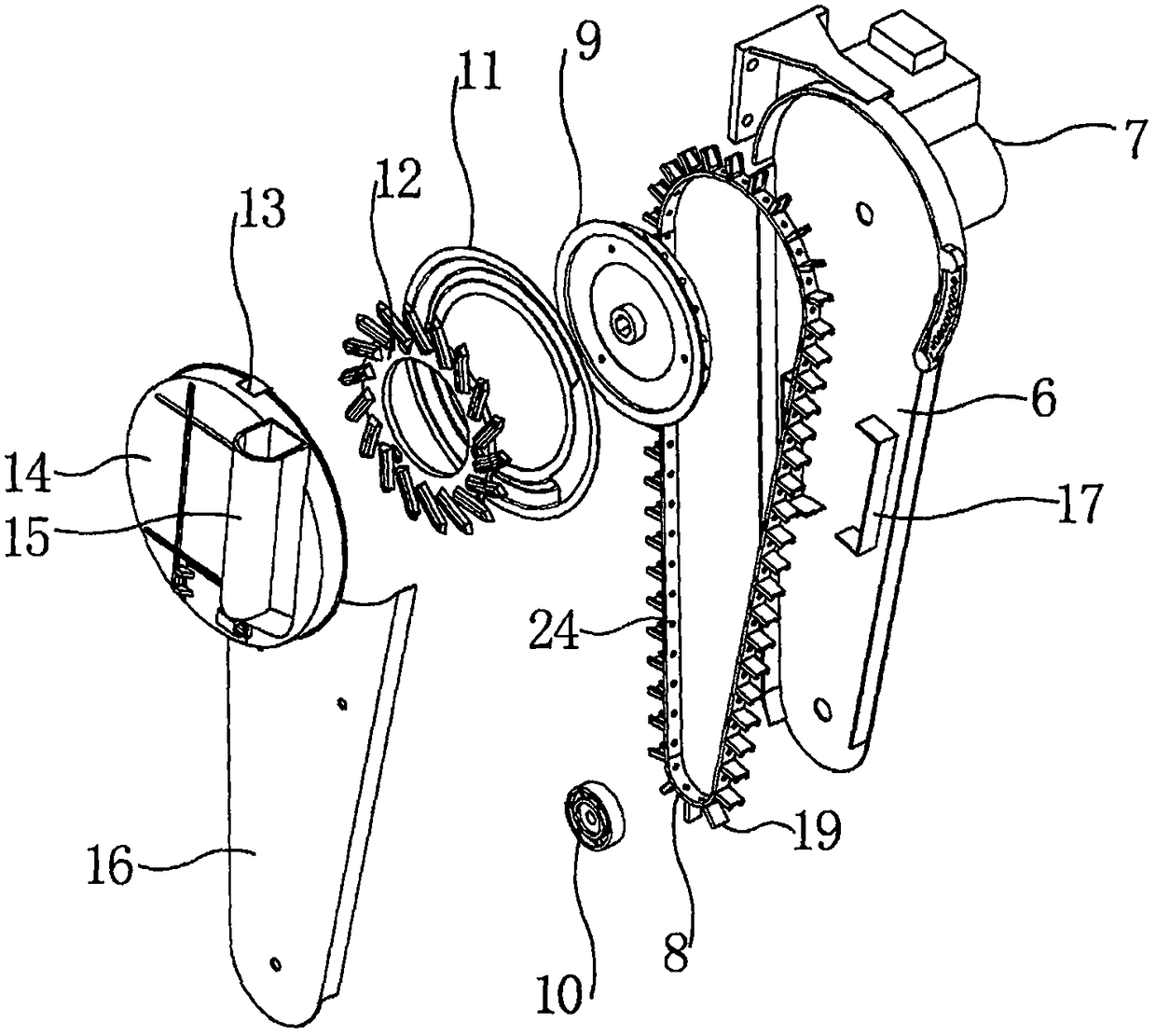

[0032] Such as image 3 , Figure 4 , Figure 11As shown, the gearbox 7 includes a gearbox housing 25, a bracket 26, a driving gear 27, an intermediate gear 28, a driving gear shaft 29, a driven gear shaft 30, a driven gear 31 and a shift handle 32, and the casing 6 and the gearbox housing 25 Connect to form a cavity for placing the conveyor belt 8, the driving gear shaft 29 and the driven gear shaft 30 pass through the casing 6 and the gearbox housing 25, the shaft end of the driving gear shaft 29 is equipped with a driving sprocket, and the driven gear shaft 30 Drive gear 9 is installed at the shaft end, drive gear 27 is installed on the drive pinion shaft 29, passive gear 31 is installed on the driven pinion shaft 30, shift handle 32 is connected with drive gear 27 and intermediate gear 28 by support 26, drive gear 27 and The passive gear 31 transmits power through the intermediate gear 28, and the power is transmitted from the driving gear 27 to the intermediate gear 28,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com