System for evaluating removing transferring and recycling material which is not dried completely

A completely dry and incomplete technology, applied in the field of material systems, can solve problems such as inability to apply in situ, difficulty in detecting and removing dried materials, uneven transmission speed of transmission devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

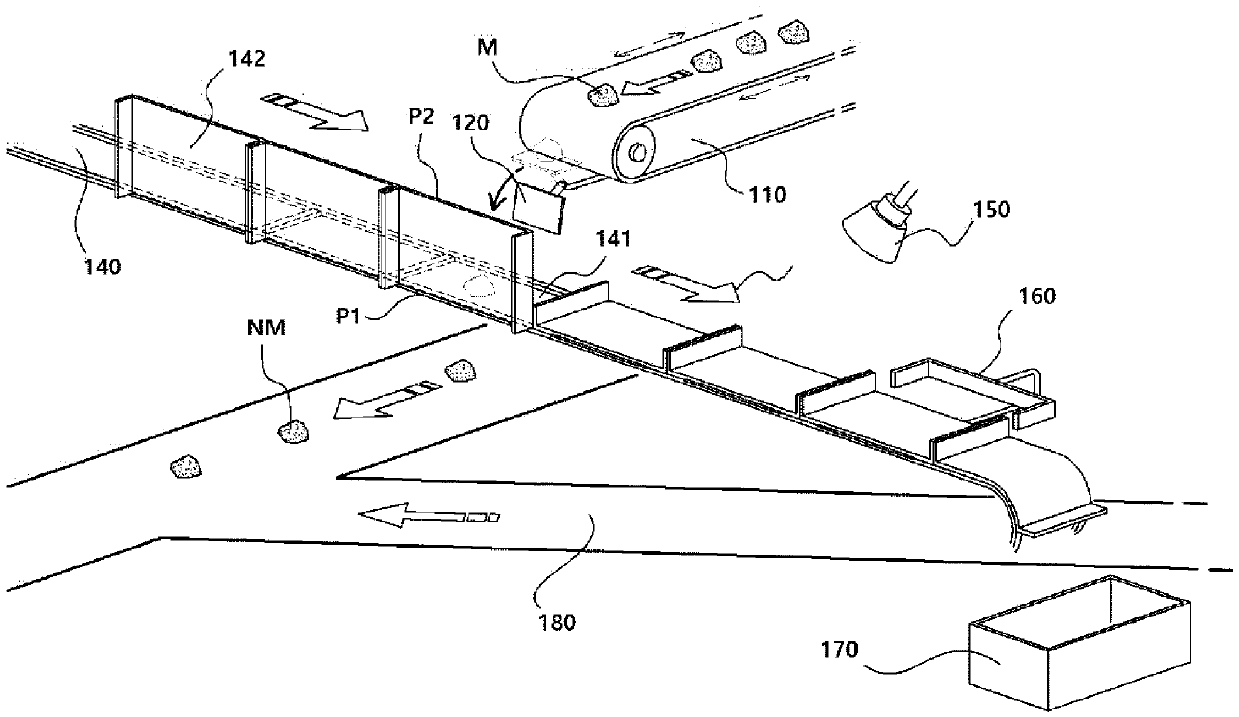

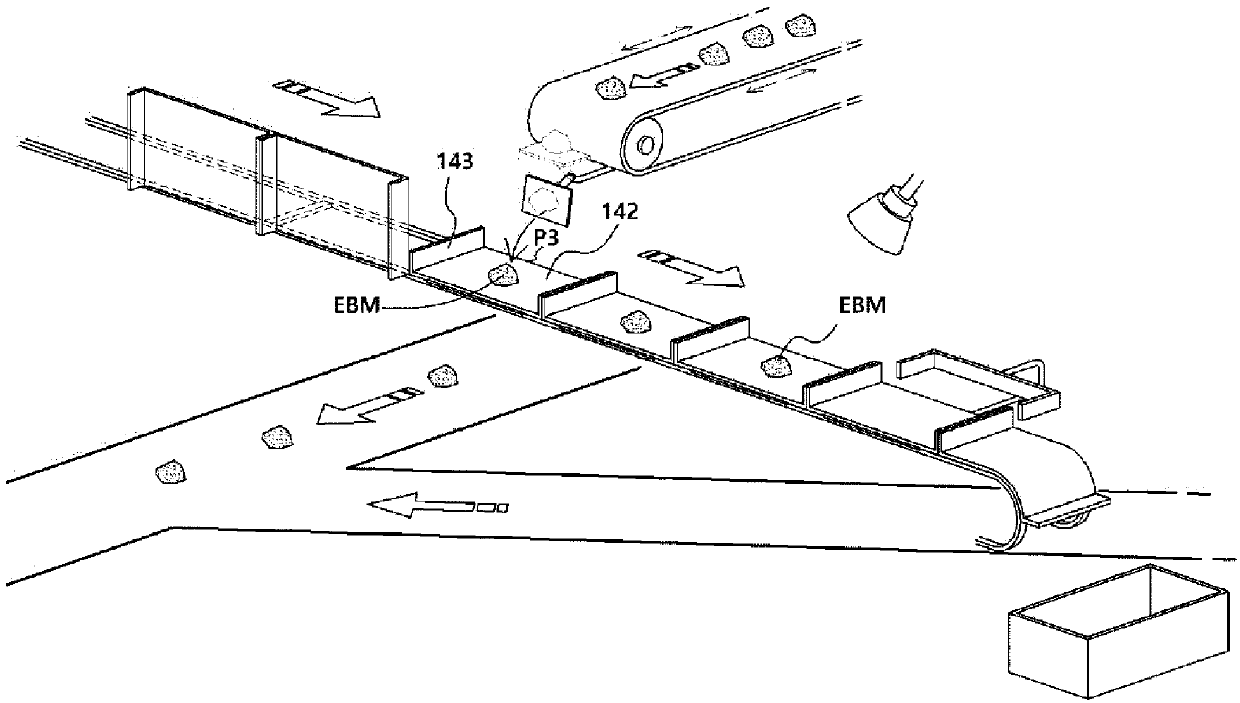

[0031] Exemplary embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. However, the present invention can be changed in various forms without being limited to these embodiments.

[0032] Here, the term "perfectly dried material (DM)" refers to a material having little or no solvent in it after the material containing the solvent has been dried, and the term "not completely dried material" refers to a material in which some or all of the solvent remains. The material of the solvent, and the term "estimated not completely dried material (ENDM)" refers to material in which it is estimated that some or all of the solvent will remain. The solvent refers to a solvent including but not limited to water, oil or acetone.

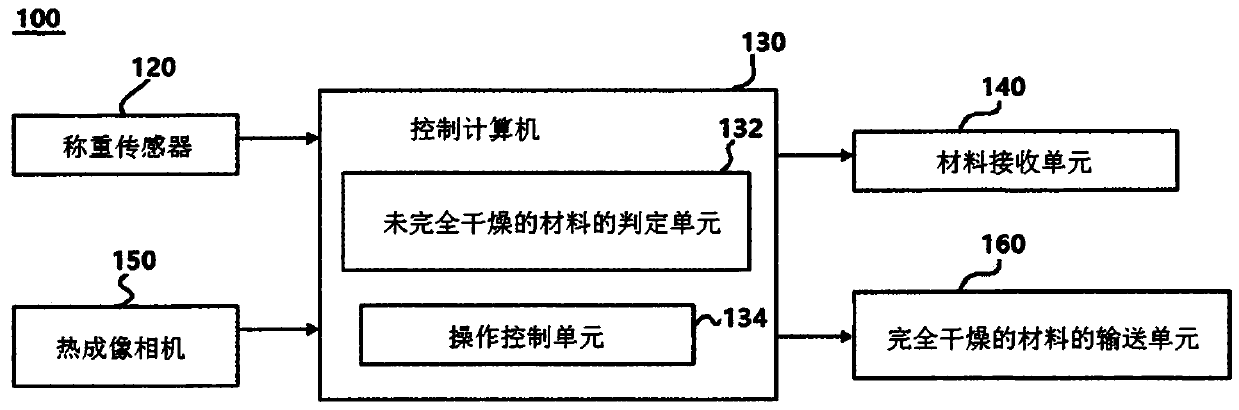

[0033] The present invention provides a system for detecting, removing, conveying and recovering incompletely dried material from material undergoing a drying process, said system comprising:

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com