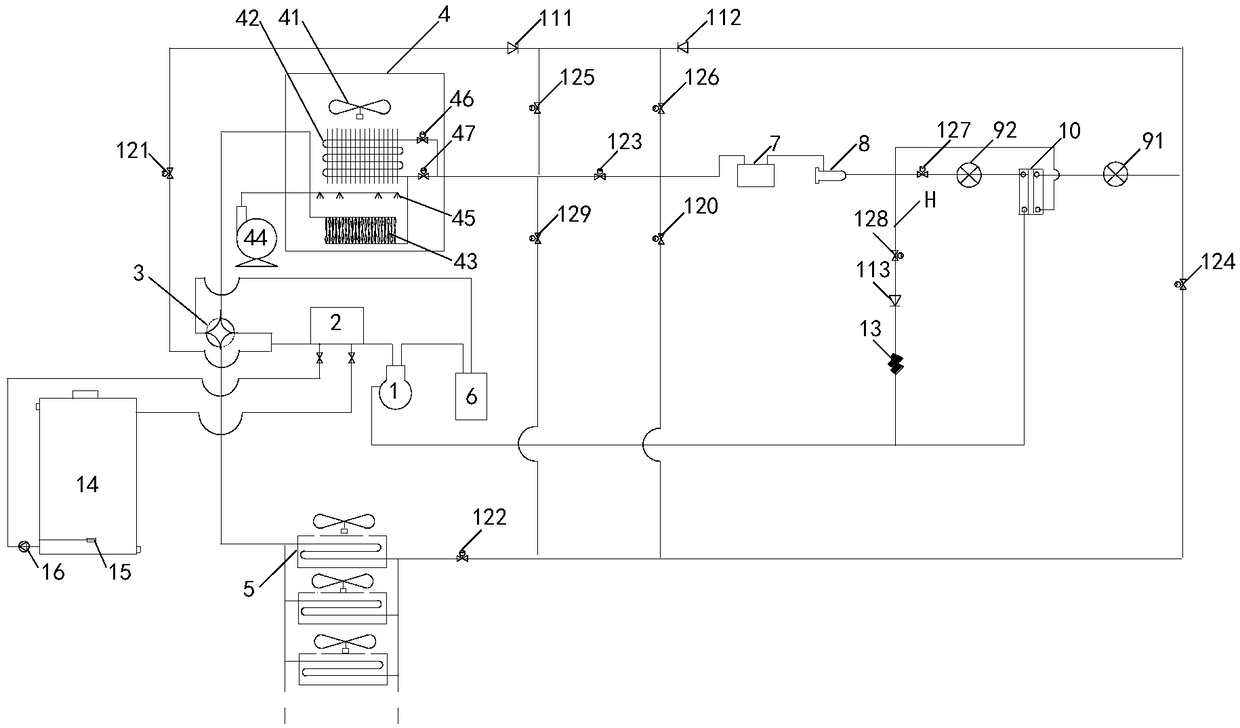

Evaporative cooling heat pump assembly

A heat pump unit, evaporative cooling technology, applied in the direction of refrigerators, refrigeration components, compressors, etc., can solve the problems of cumbersome control system, high frequency conversion of unit functions, complicated pipelines, etc., so as to reduce the use cost and improve the heat recovery efficiency. , Improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

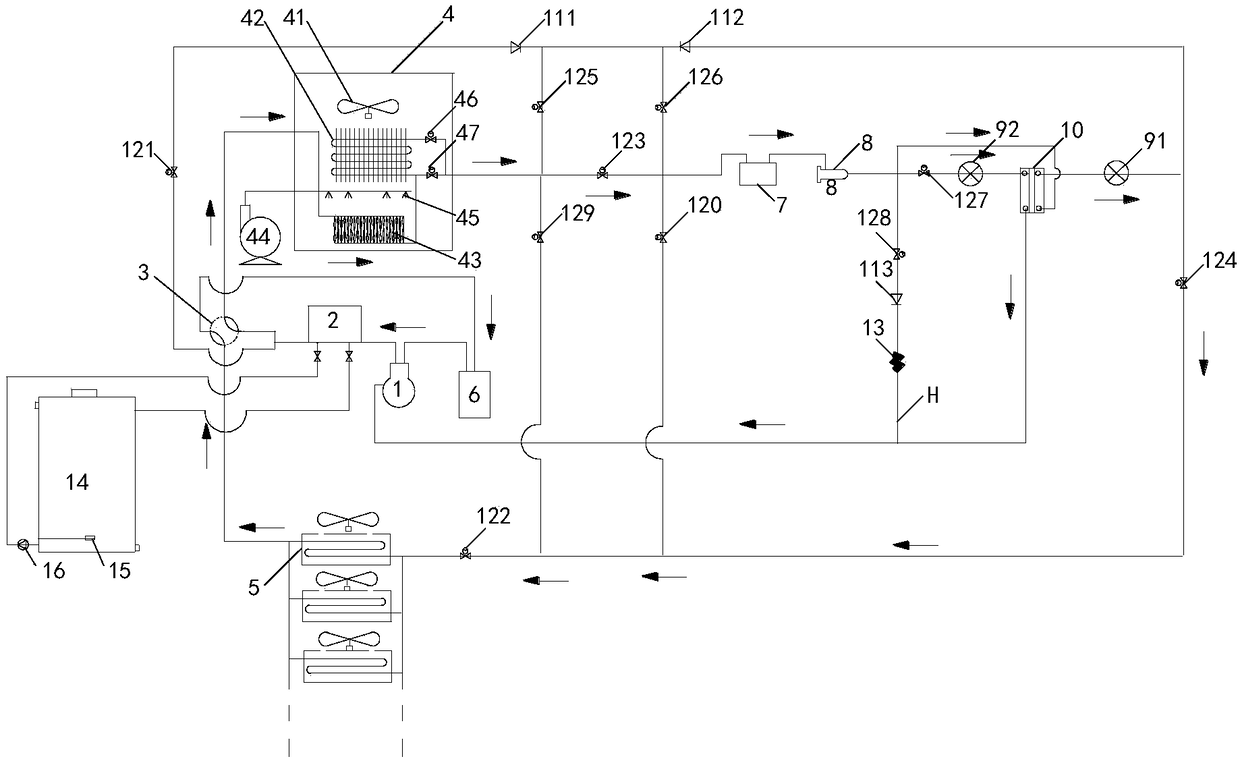

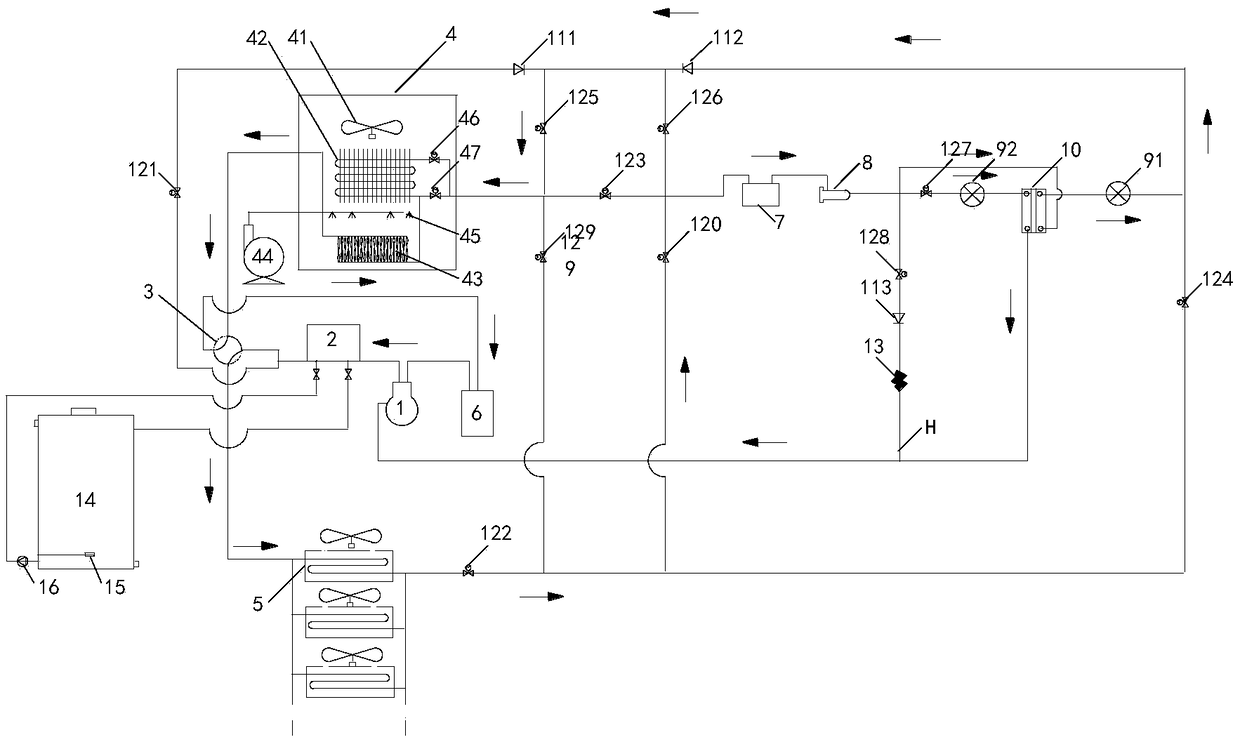

[0117] The evaporative cooling and heat pump unit in this embodiment also includes a domestic water tank 14 connected to the heat recovery device 2, a temperature sensing probe 15 arranged in the domestic water tank 14, and a water outlet connected to the heat recovery device 2 and the inlet of the domestic water tank 14. Hot water circulation pump 16 between water ports. The above components are activated in all hot water modes.

[0118] At this time, the first electromagnetic valve 121 is closed, and the heat recovery device 2 is connected in series with the evaporative cooling heat exchange unit 4 and the indoor heat exchanger 5. At this time, the temperature sensing probe 15 detects that the temperature of the domestic water tank 14 is lower than the set value T1 (eg: 45°C), the first solenoid valve 121 is closed, the hot water circulation pump 16 is turned on until the hot water reaches the set temperature, the circulation pump 16 is closed, and the unit enters the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com