Low-chromatic aberration concrete

A technology of concrete and concrete synergist, which is applied in the field of construction concrete, which can solve the problems of aesthetics reduction, concrete color difference, etc., and achieve the effects of easy decontamination, reduced ripples, and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

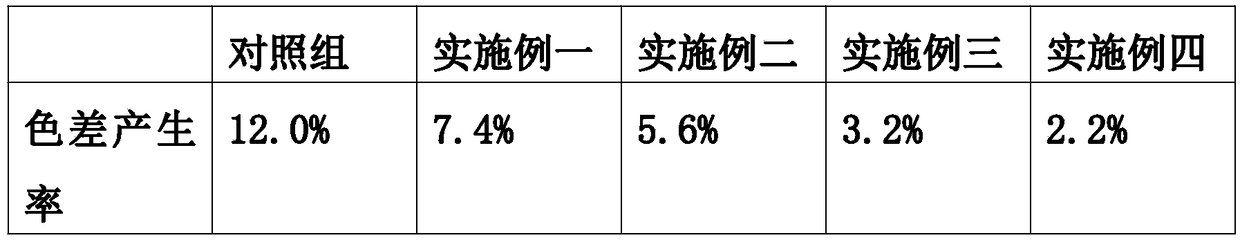

Examples

Embodiment 1

[0016] Embodiment 1: a kind of low chromatic aberration concrete, by weight, comprises the following components:

[0017] 160 parts of cement, 50 parts of mineral powder, 70 parts of fly ash, 1000 parts of stone, 90 parts of sand, 300 parts of water, 20 parts of film former, 8 parts of water reducing agent, and 2 parts of CTF concrete synergist.

[0018] Cement grades can be selected as strength grades of 32.5, 32.5R, 42.5 or 42.5R, and 32.5R cement should be selected in consideration of cost; It is 17-19μm; the particle size of the stone is 15-25mm, the fineness modulus of the sand is 2.2-1.6, and the average particle size is 0.35-0.25mm, that is, fine sand.

[0019] The film-forming agent is water-based polyurethane, and the water-reducing agent is a water-soluble resin sulfonate water-reducing agent. The CTF concrete synergist adopts the CTF concrete synergist of Guangzhou Sanjun Building Materials Technology Co., Ltd.

[0020] The parameters of the above-mentioned compon...

Embodiment 2

[0021] Embodiment 2: a kind of low chromatic aberration concrete, by weight, comprises the following components:

[0022] 240 parts of cement, 80 parts of mineral powder, 120 parts of fly ash, 1100 parts of stone, 180 parts of sand, 400 parts of water, 30 parts of film former, 14 parts of water reducer, and 4 parts of CTF concrete synergist.

Embodiment 3

[0023] Embodiment 3: a kind of low chromatic aberration concrete, by weight, comprises the following components:

[0024] 200 parts of cement, 65 parts of mineral powder, 95 parts of fly ash, 1050 parts of stone, 135 parts of sand, 350 parts of water, 25 parts of film former, 11 parts of water reducing agent, and 3 parts of CTF concrete synergist.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com