Novel motor having waterproof performance

A high-performance, new technology, applied in the field of new waterproof motors, can solve the problems of land occupation, time-consuming, human and environmental factors, etc., to achieve the effect of ensuring reliability, improving sealing, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

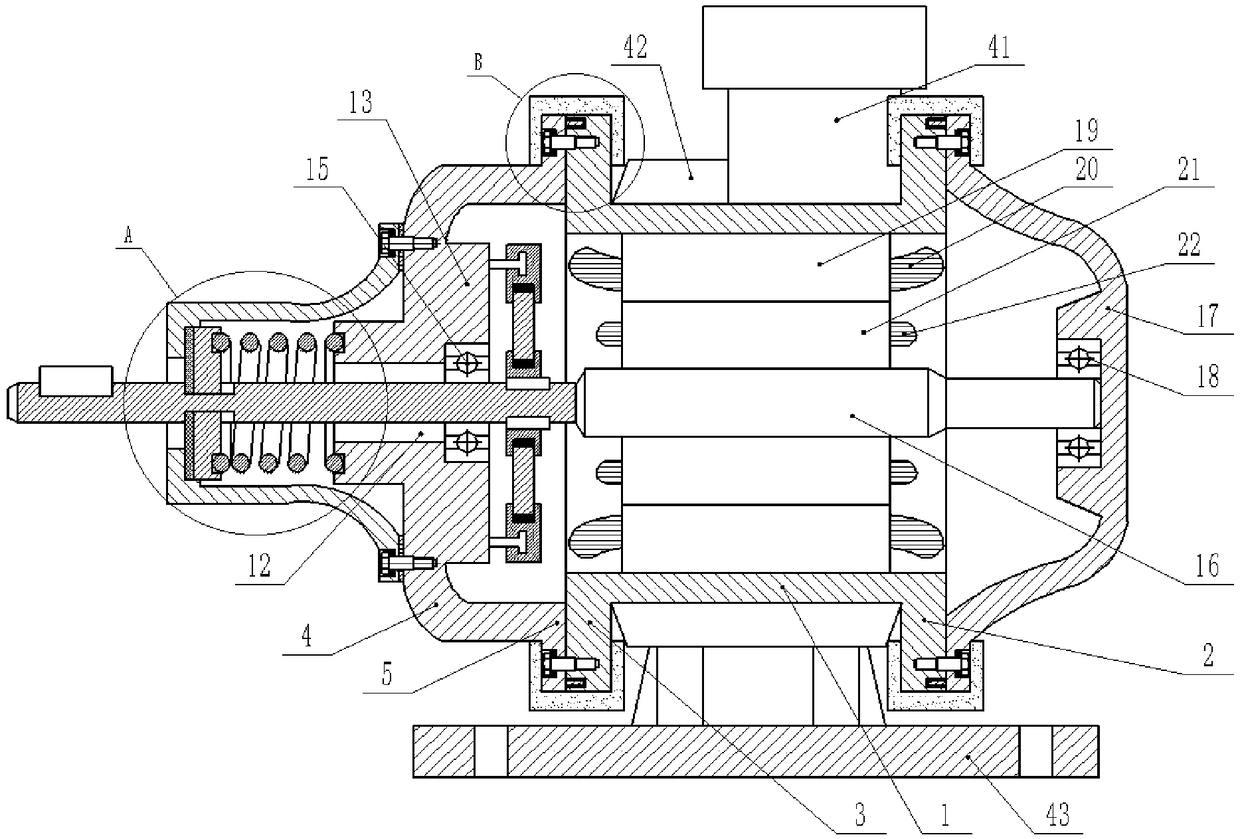

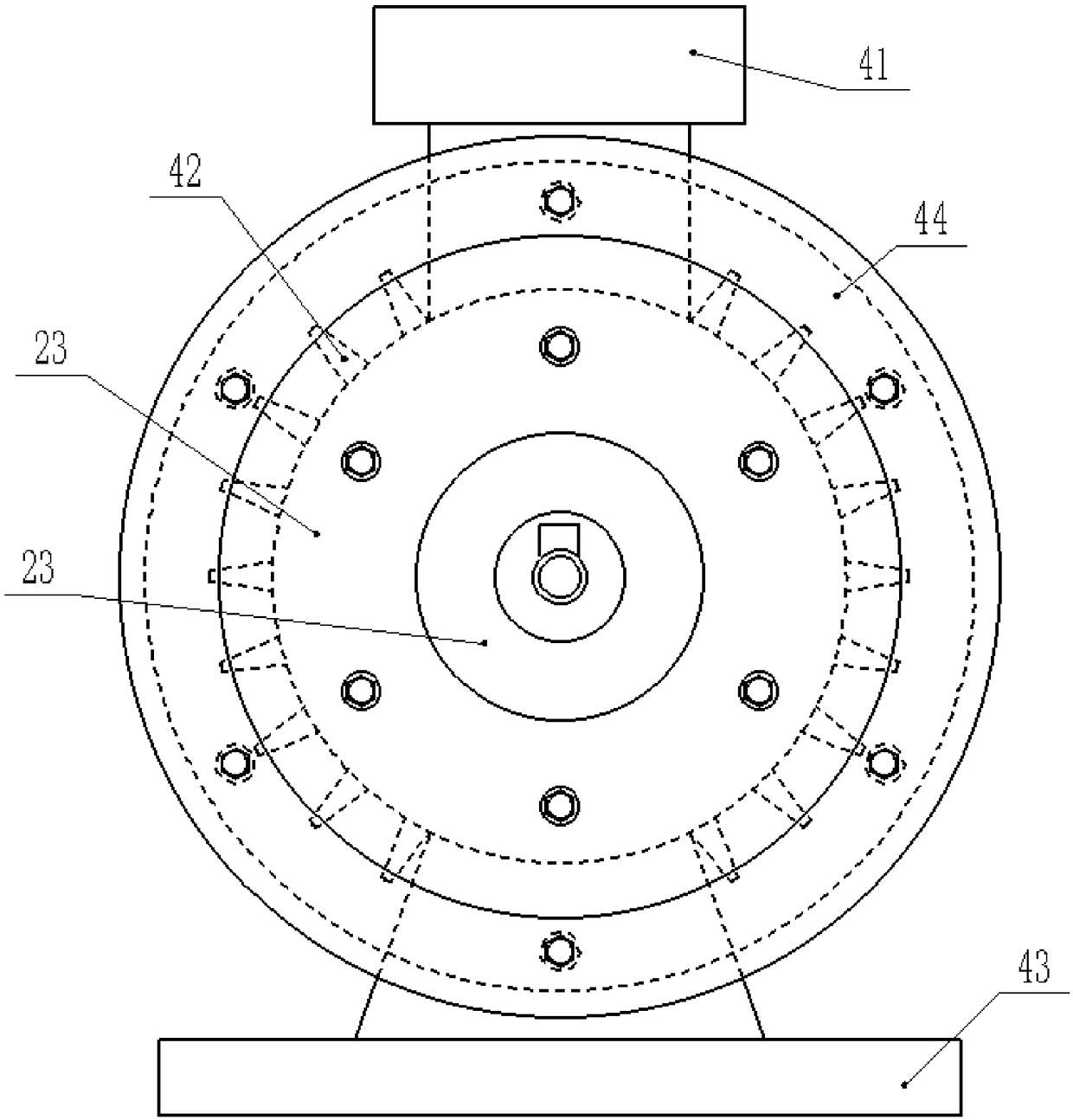

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a new type of motor with waterproof performance includes a casing 1, a front end cover 4, a rear end cover 17 and several bolts 7, and it is characterized in that: the two ends of the casing 1 are respectively provided with right Protruding ring 2 and left protruding ring 3, one end of the front end cover 4 is provided with a front end cover protruding ring 5 integrally formed with it, the other end of the front end cover 4 is provided with a cover body 23, and the front end cover protruding ring 5 passes through a plurality of The bolt 7 is fixed with the left convex ring 3, and the rear end cover 17 is fixed with the right convex ring 2 by the bolt 7. The front end cover 4 is provided with an end cover through hole 12 on an end next to the cover body 23, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com