Reinforced sealing flat cap intensity checking method

A strength check, flat cover technology, applied in gas/liquid distribution and storage, instrumentation, electrical digital data processing, etc. Problems such as checking the strength of the reinforced sealing flat cover, etc., have achieved the effect of obvious economic benefits and ensuring safe service.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific implementation mode one: the method for checking the strength of the reinforced sealed flat cover of the present implementation mode includes the following steps:

[0037] Step 1: Calculate the thickness of the unreinforced flat cover according to the flange design method of the pressure vessel design standard;

[0038] Step 2: Determine the thickness of the reinforced flat cover and take 0.55 times the thickness of the non-reinforced flat cover;

[0039] Step 3: Check the structural strength of the dangerous section of the flat cover;

[0040] Further, in step 1, according to the flange design method of the pressure vessel design standard specification, the specific method for calculating the thickness of the unreinforced flat cover is:

[0041] 1 Find the width of the contact surface between the rib flat cover and the pressure vessel installation gasket

[0042] N=(D1-D2) / 2

[0043] In the formula, N is the width of the gasket contact surface, D1 is the ou...

specific Embodiment approach 2

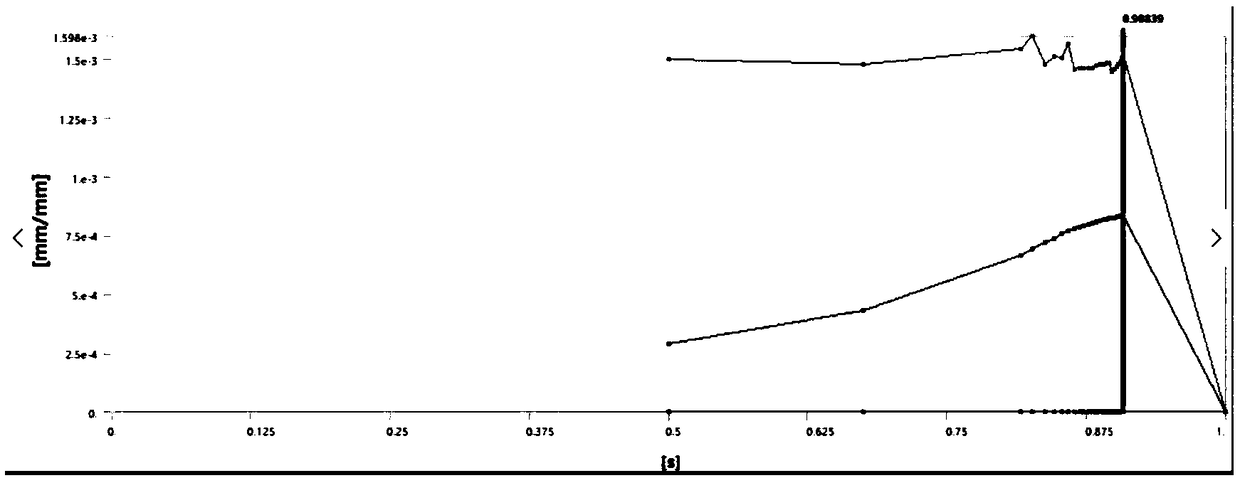

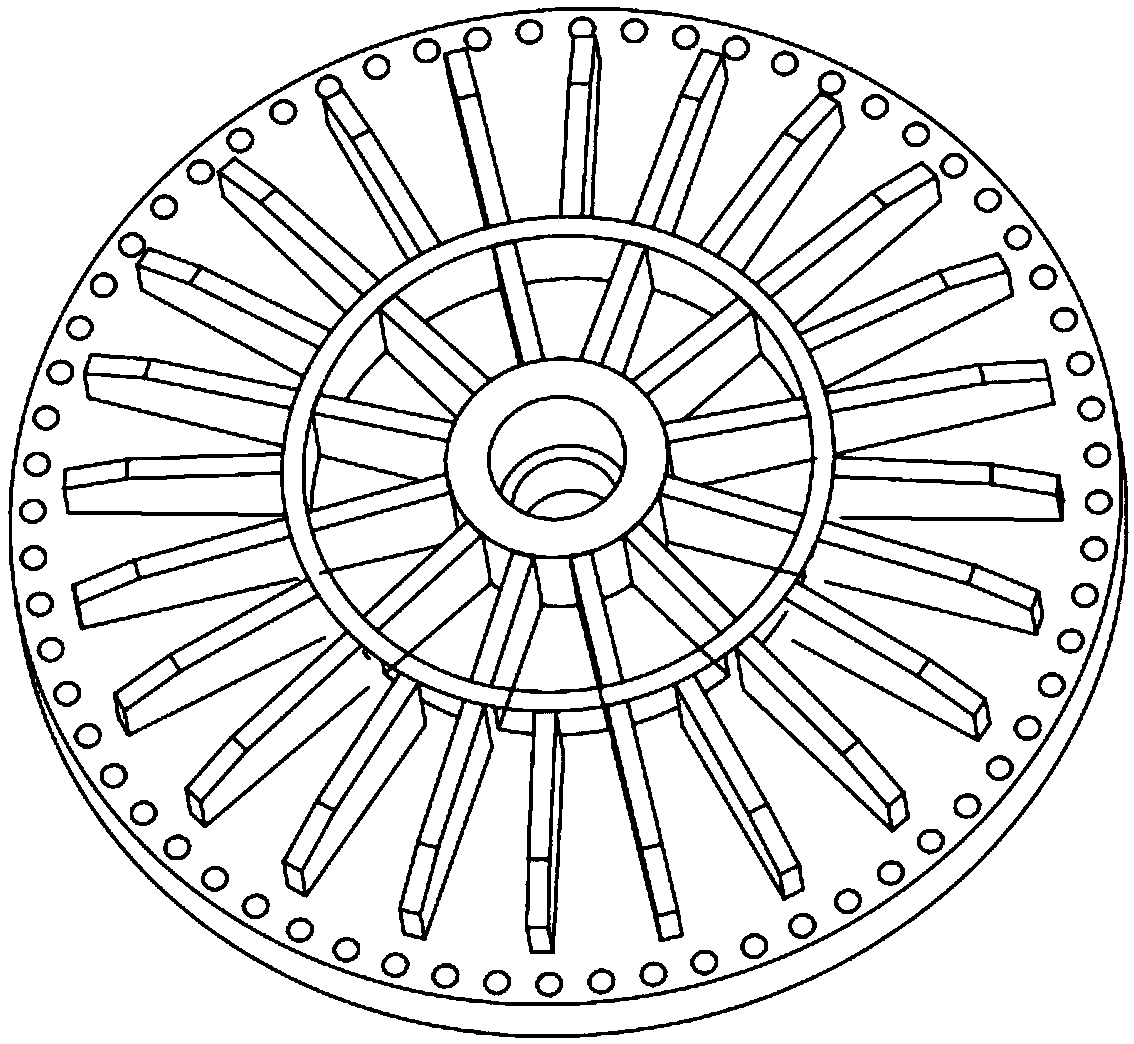

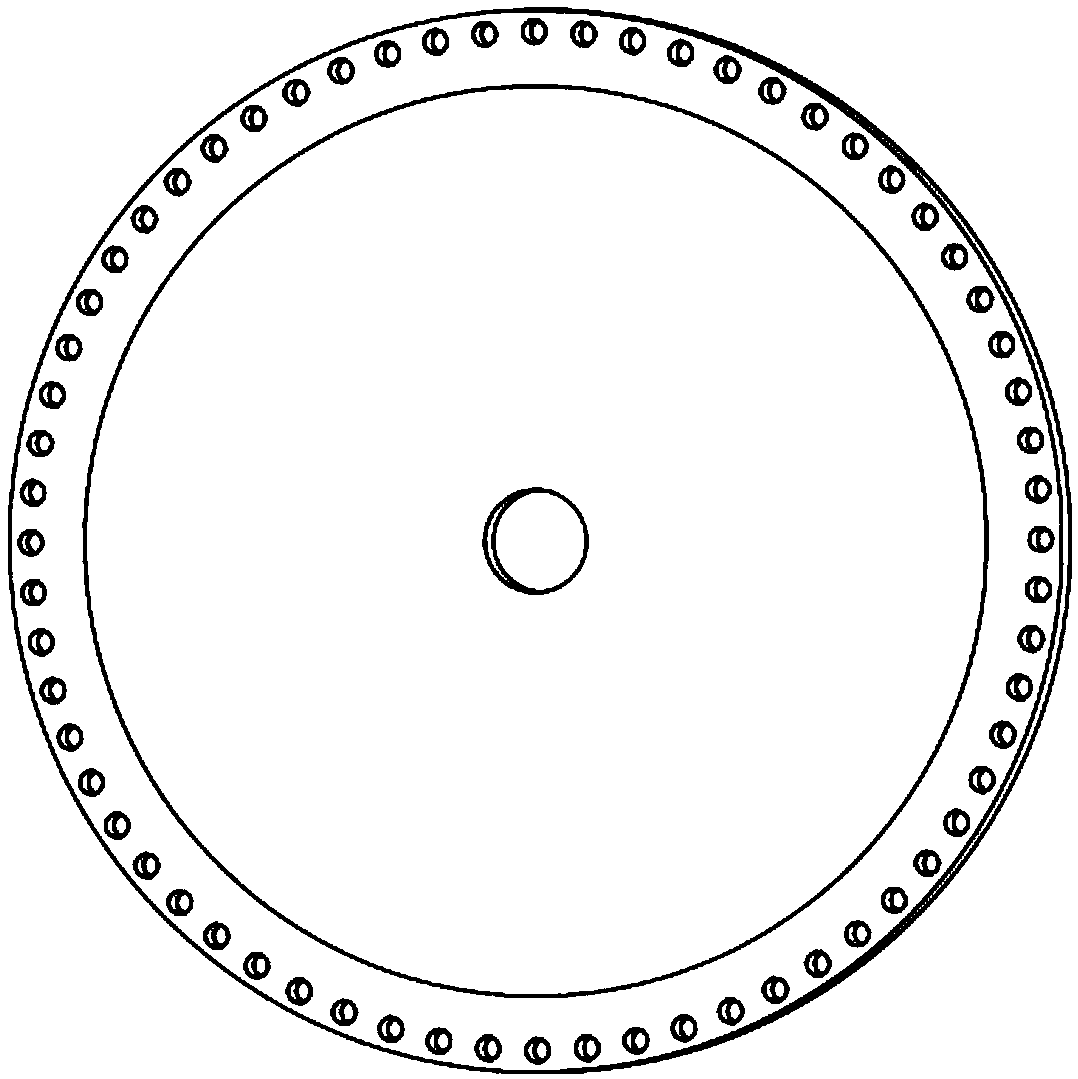

[0108] Specific embodiment two: the method for checking the strength of the reinforced sealing flat cover of the present embodiment, applying this patent, needs to use the numerical method to solve the stress condition of the dangerous section of the structure, to meet the requirements of the structural limit analysis, the local area (sealing surface area) ) should meet the assessment requirements of the stress classification method; the reliability of the seal at the sealing surface should be judged based on the calculation results of the numerical method. The following is an example of the actual project, the structure diagram is shown in the instruction manual image 3 , Figure 3a , Figure 3b and Figure 3c , explain the principle of this patent:

[0109] image 3 Among them, ① reinforced flat cover; ② flange; ③ cylinder section; ④ strip rib; ⑤ O-shaped rubber ring;

[0110] The flat cover is at the diameter of Φ2656, which is also the dangerous section where the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com