Capacitive pressure detection method

A detection method, capacitive technology, applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc., can solve the problems of forming pressure detection capacitance, unable to realize pressure detection, difficult to control the thickness of air gap, etc., to achieve Securing capacitance change rate, securing gap thickness, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

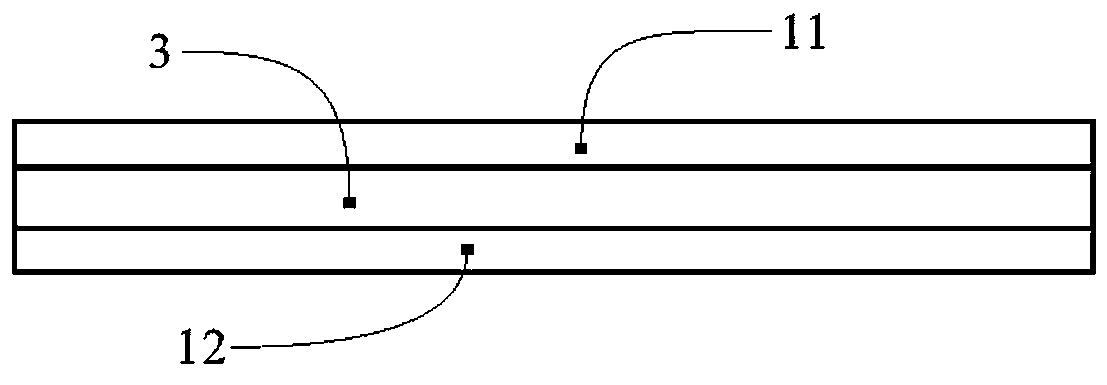

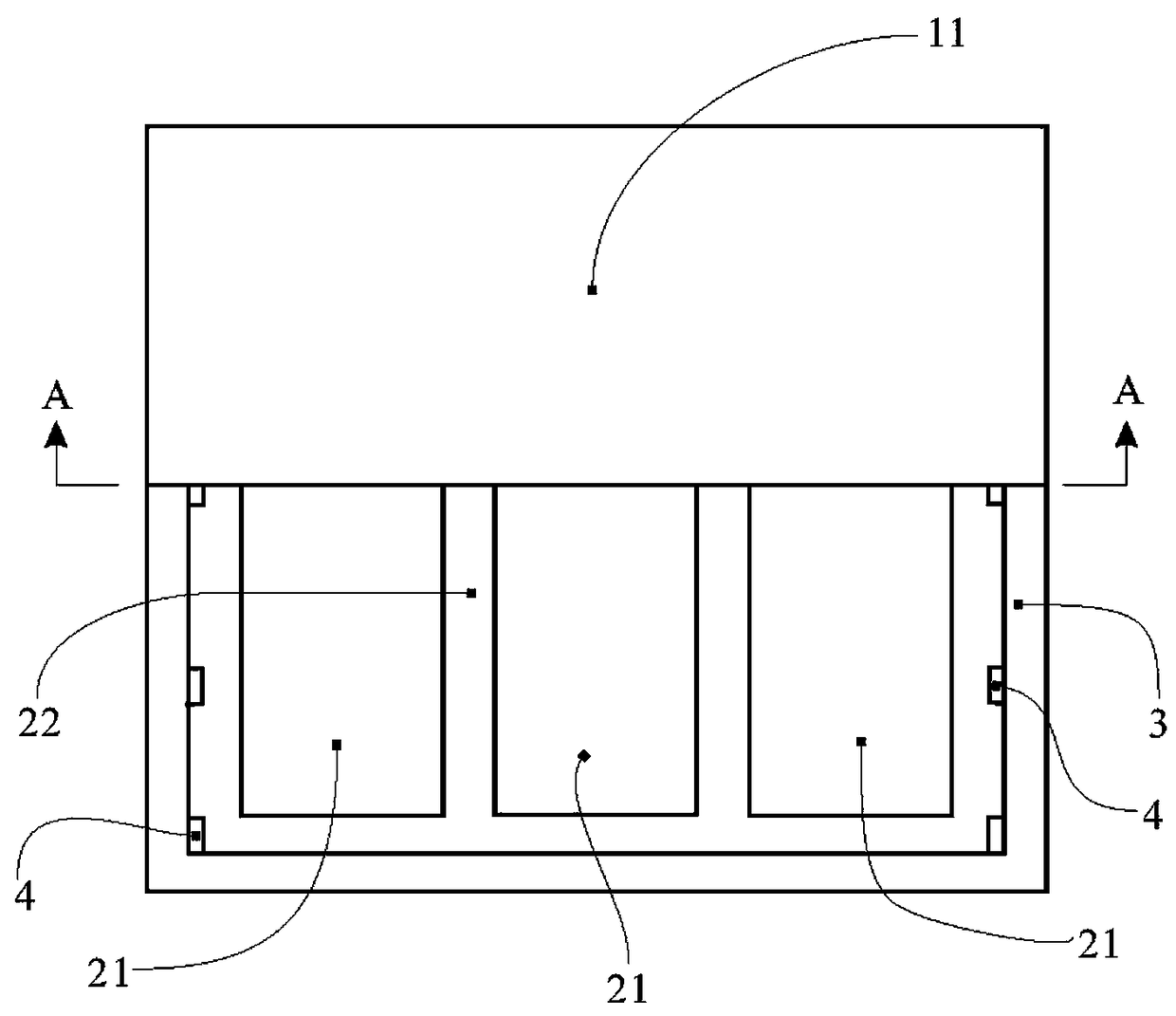

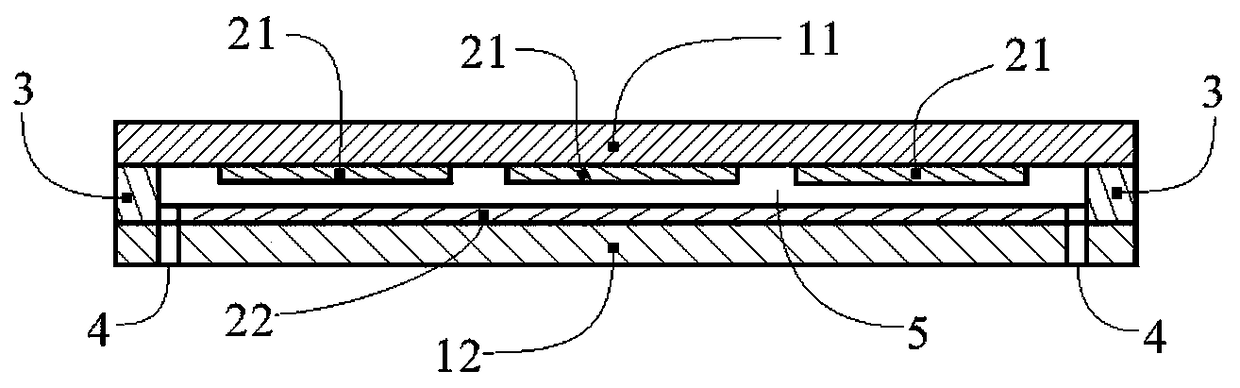

[0055] In the first embodiment of the present invention, the Young's modulus of the material used to manufacture the first substrate 11 is smaller than the Young's modulus of the material used to manufacture the second substrate 12;

[0056] The first base material 11 is attached under the display module of the display screen as a pressure bearing surface.

[0057] The Young's modulus of the first base material 11 is smaller than the Young's modulus of the second base material 12, so that the first base material 11 as the pressure bearing surface is more easily deformed than the second base material 12, thereby increasing the thickness of the gap 5 The change range increases the capacitance change rate of the pressure detection capacitor and improves the pressure detection sensitivity.

[0058] Similarly, another specific method to increase the deformation of the pressure-bearing surface by using different materials is:

[0059] Making the Young's modulus of the material used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com