Capacitive pressure detection device

A detection device and capacitive technology, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of forming pressure detection capacitors, difficult to control the thickness of air gaps, and unable to realize pressure detection, etc. The effect of securing the capacitance change rate, securing the gap thickness, and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further details will be given below in conjunction with various embodiments shown in the accompanying drawings.

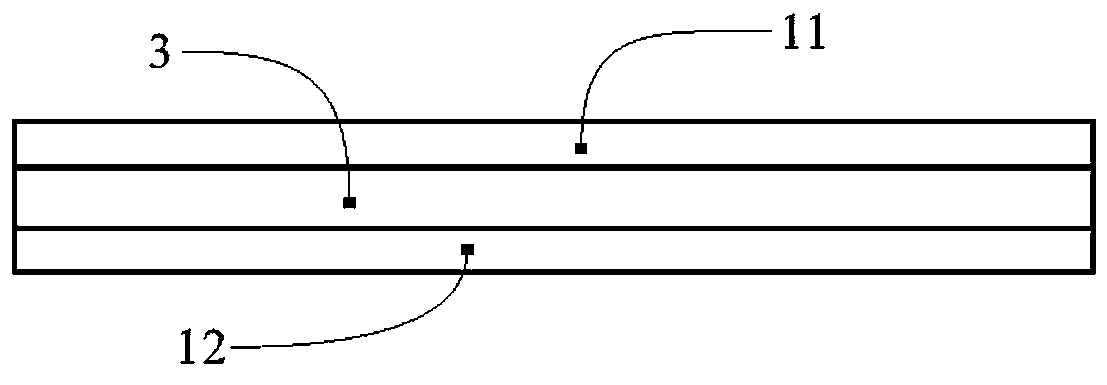

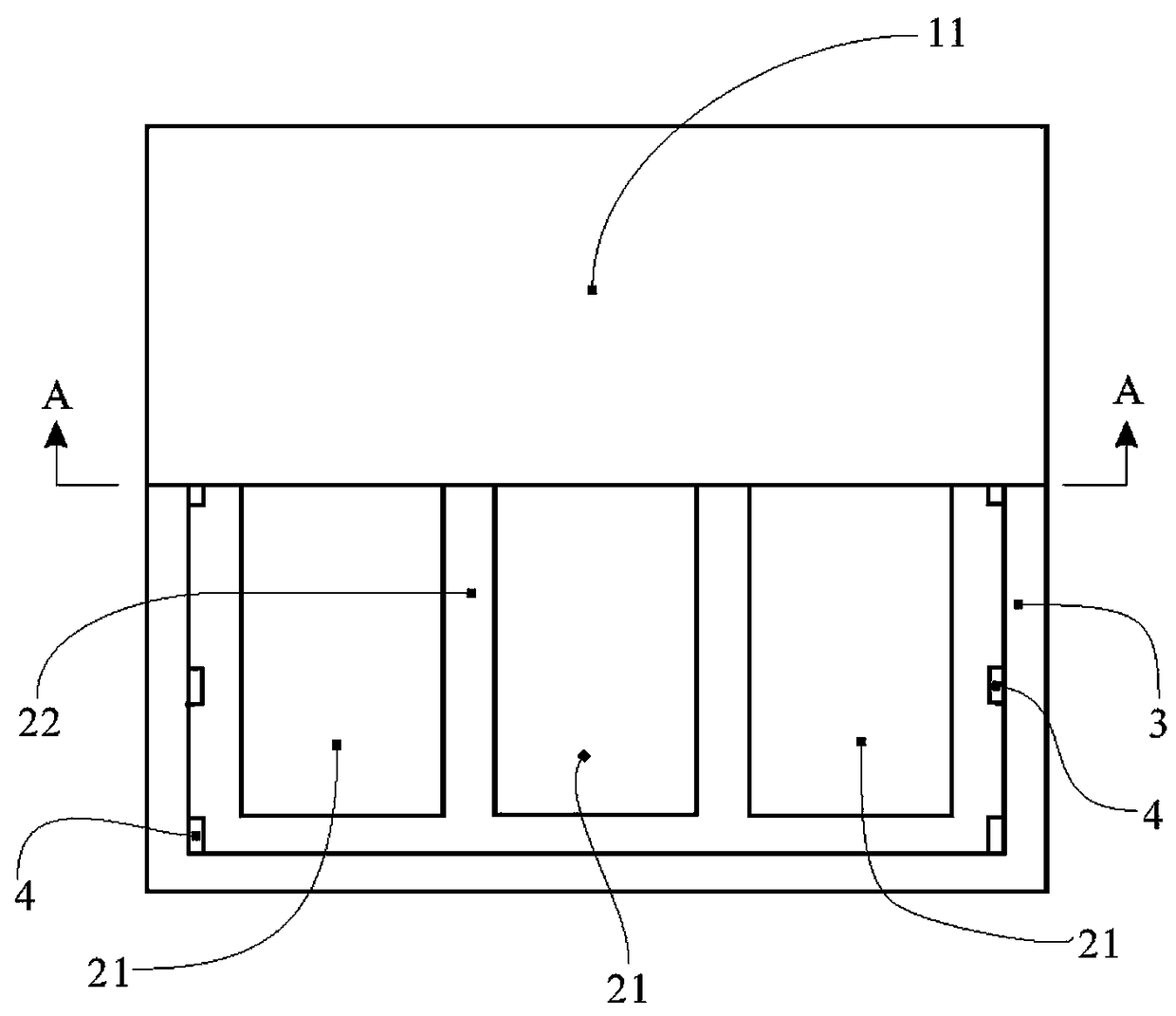

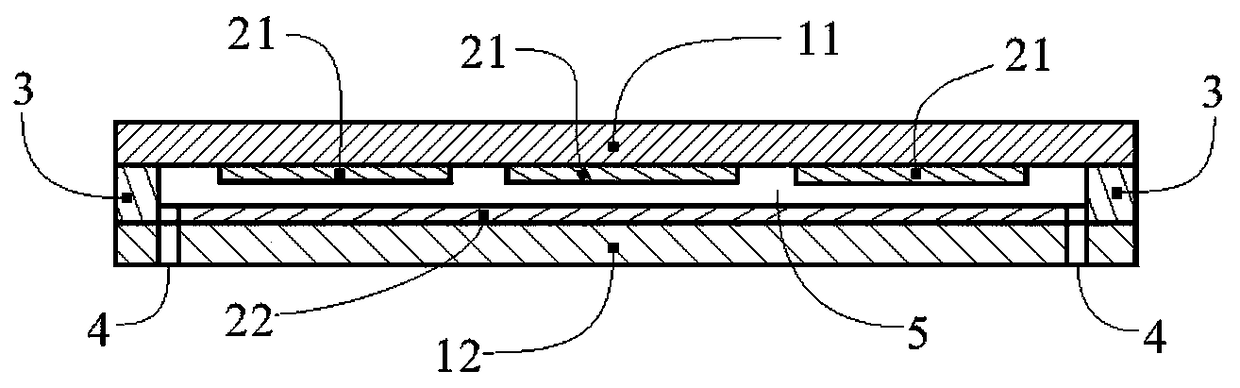

[0031] The invention provides a capacitive pressure detection device for detecting the pressing force applied on the display screen. The pressing force applied on the display screen is different from the touch input to the screen. The pressing force is to exert pressure on the display screen, while the touch input does not need to apply pressure, but only needs to have contact with the display screen. The display screen includes a display module capable of being deformed by pressing on the display screen. Such as Figure 1 to Figure 7As shown, the capacitive pressure detection device includes a first substrate 11 and a second substrate 12 that can be deformed under pressure, at least one first electrode 21 disposed on the front surface of the first substrate 11, disposed on the second substrate At least one second electrode 22 on the front surface of 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com