Damping and cooling structure of case fan

A heat dissipation structure and fan technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of poor fan installation structure stability, unsatisfactory heat dissipation performance, and stability performance to be improved. It is not easy to achieve Effects of vibration and noise, avoidance of clogging, improvement of stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0016] Example.

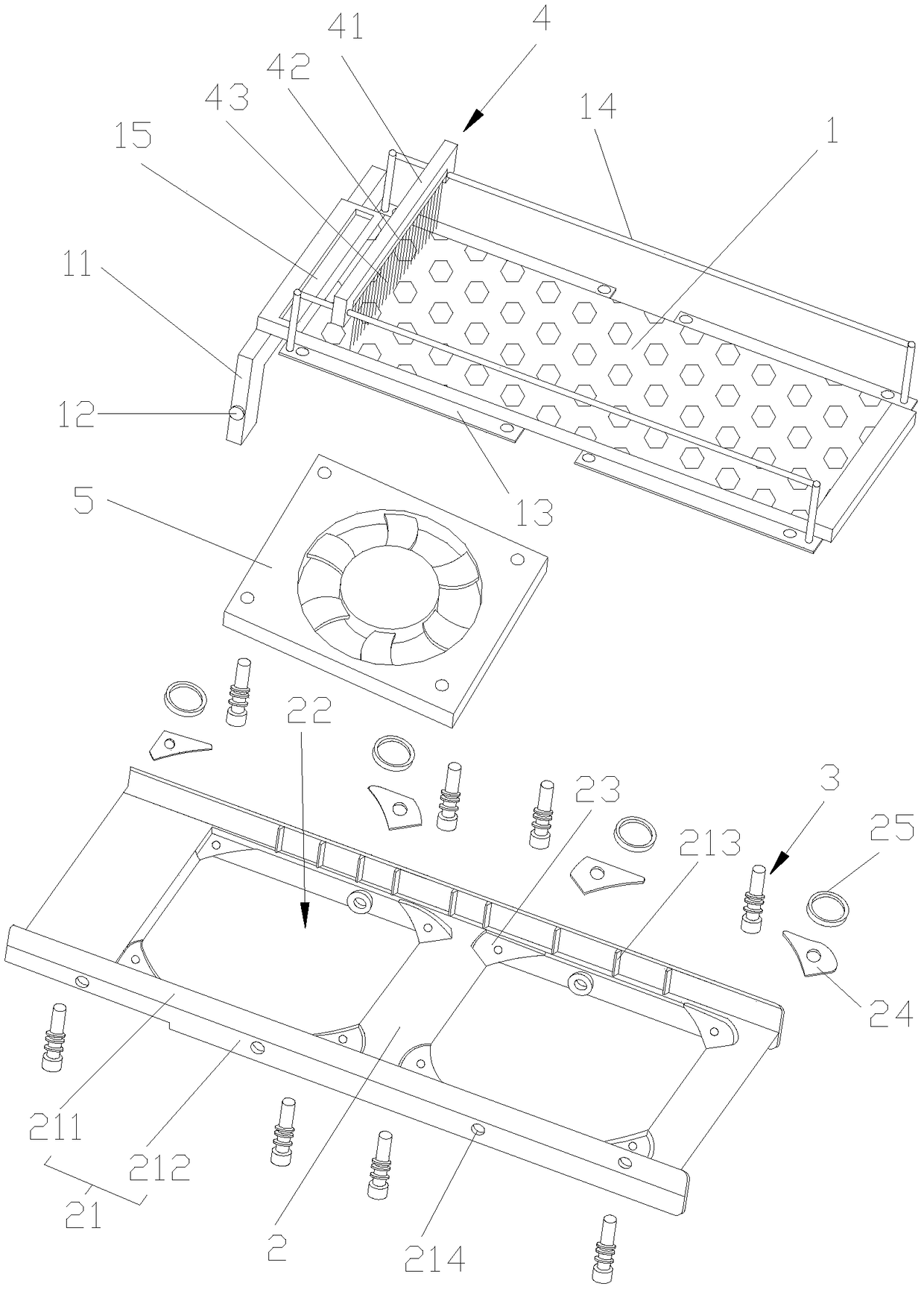

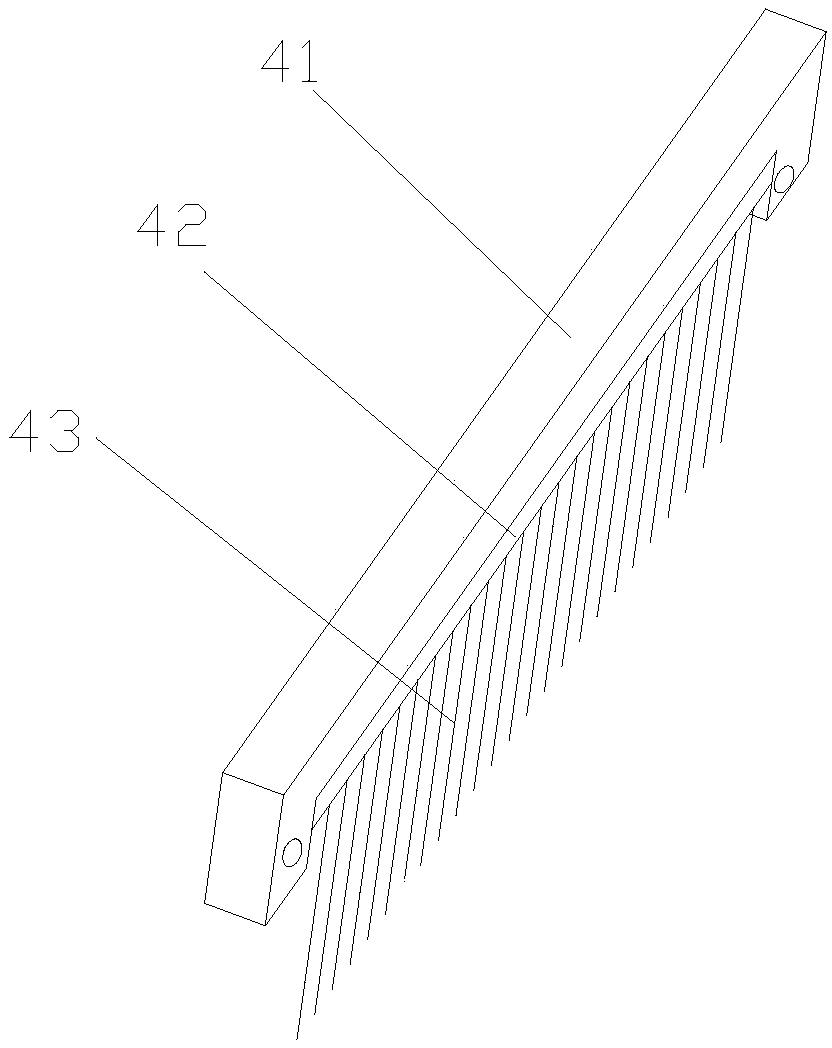

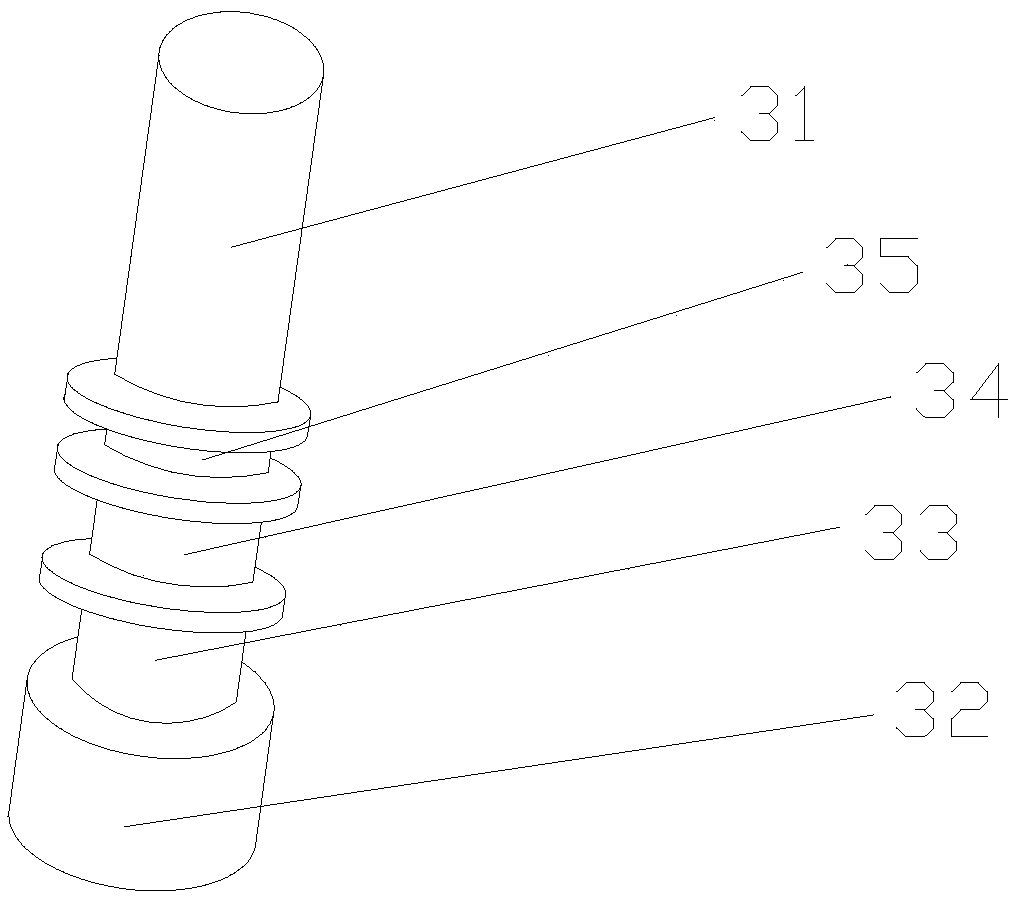

[0017] like figure 1 , figure 2 and image 3 As shown, a shock-absorbing and heat-dissipating structure of a chassis fan includes a mounting plate 2, a filter plate 1 is arranged above the mounting plate 2, and a plurality of air vents 22 for installing fans 5 are arranged on the mounting plate 2. The mounting plate 2, the periphery of the vent 22 is provided with a number of shock absorbing grooves 23, the bottom surface of the shock absorbing groove 23 is provided with heat dissipation silica gel 24, the side of the shock absorbing groove 23 is provided with a buffer ring 25, and the shock absorbing groove 23 A shock-absorbing nail 3 is provided inside, and the shock-absorbing nail 3 passes through the heat dissipation silica gel 24, the fan 5 and the filter plate 1 in turn; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com