COA type liquid crystal display panel structure and manufacturing method of COA type liquid crystal display panel structure

A technology of liquid crystal display panel and manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of inability to realize narrow frame design and large width, and achieve the effect of reducing frame width and realizing narrow frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0042] The present invention firstly provides a COA type liquid crystal display panel structure. The so-called COA type liquid crystal display panel adopts COA (Color Filter On Array) technology, and the color filter is integrated and manufactured on one side of the TFT array substrate, which can increase the aperture ratio of the liquid crystal display panel. , to reduce the effect of parasitic capacitance.

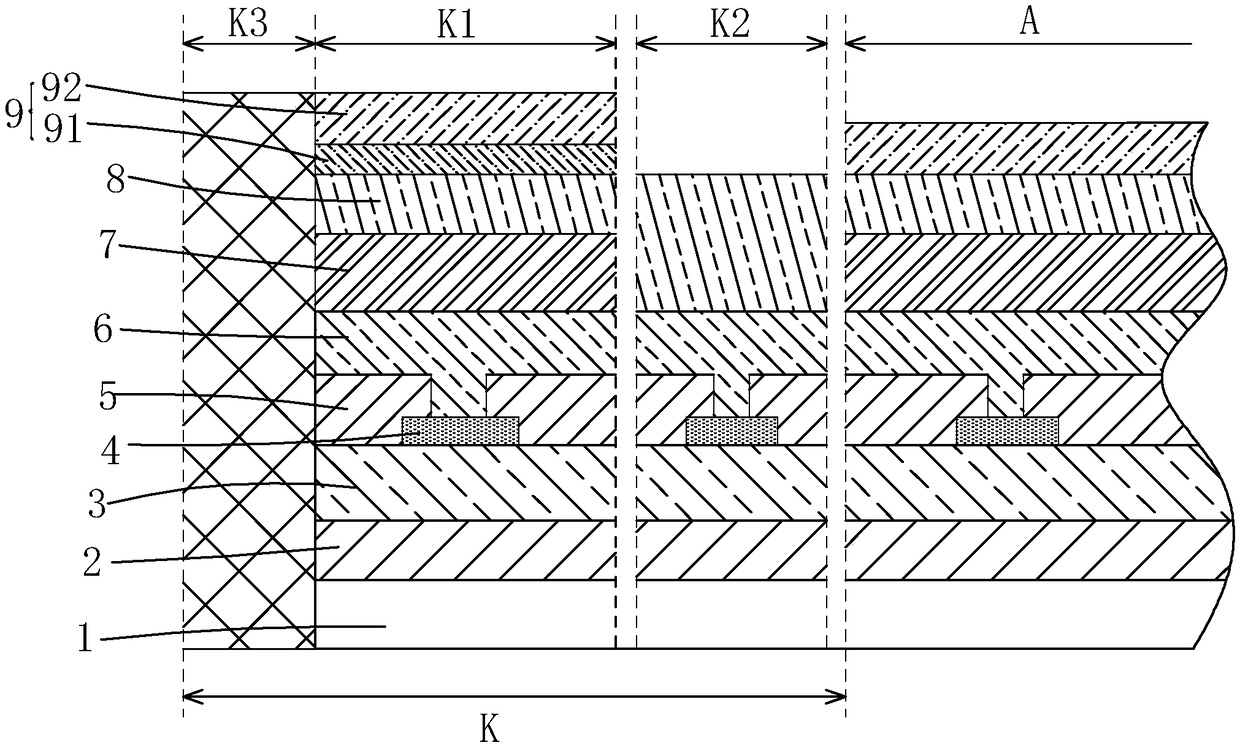

[0043] Please also see figure 2 and image 3 , The COA liquid crystal display panel structure of the present invention includes a display area A and a peripheral area K outside the display area A. According to the order from near to far from the display area A, the peripheral area B includes an electrostatic protection area K2, a GOA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com