Double-layer running gel dyeing device, automatic running gel drying device and use method thereof

A dyeing device and double-layer electrophoresis technology, applied in the field of molecular biology, can solve the problems of inability to completely absorb the dye solution, affect imaging, and cumbersome operation, and achieve strong innovation and practical value, high degree of automation, and practical operation strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

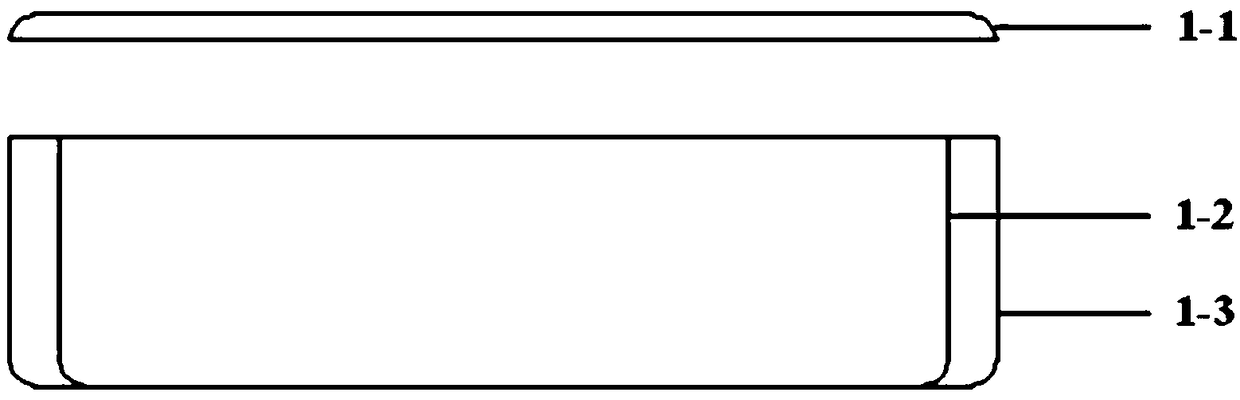

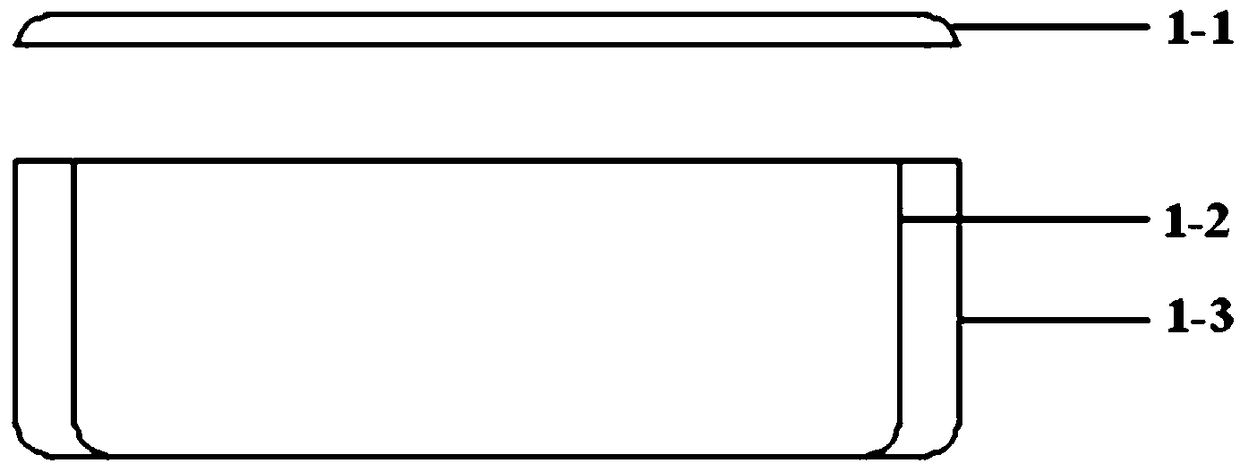

[0042] The preparation of embodiment 1 double-layer electrophoresis gel staining device

[0043] 1. Materials

[0044] (1) double-layer electrophoresis gel dyeing device: plastics, iron, stainless steel, and ceramic containers with different sizes (this method can be prepared into a dyeing device of any corresponding specification according to the specifications of the electrophoresis gel, because the electrophoresis gel used in the test of this embodiment is 13cm, the dyeing device lining is designed to be long 18cm, wide 14cm, high 5cm, and the outer layer is long 20cm, wide 16cm, high 5cm). In the actual experiment, the number of dyeing devices can be adjusted according to the number of glue.

[0045] (2) Punching device: punching machine.

[0046](3) Empty colloids prepared by conventional methods.

[0047] 2. Method

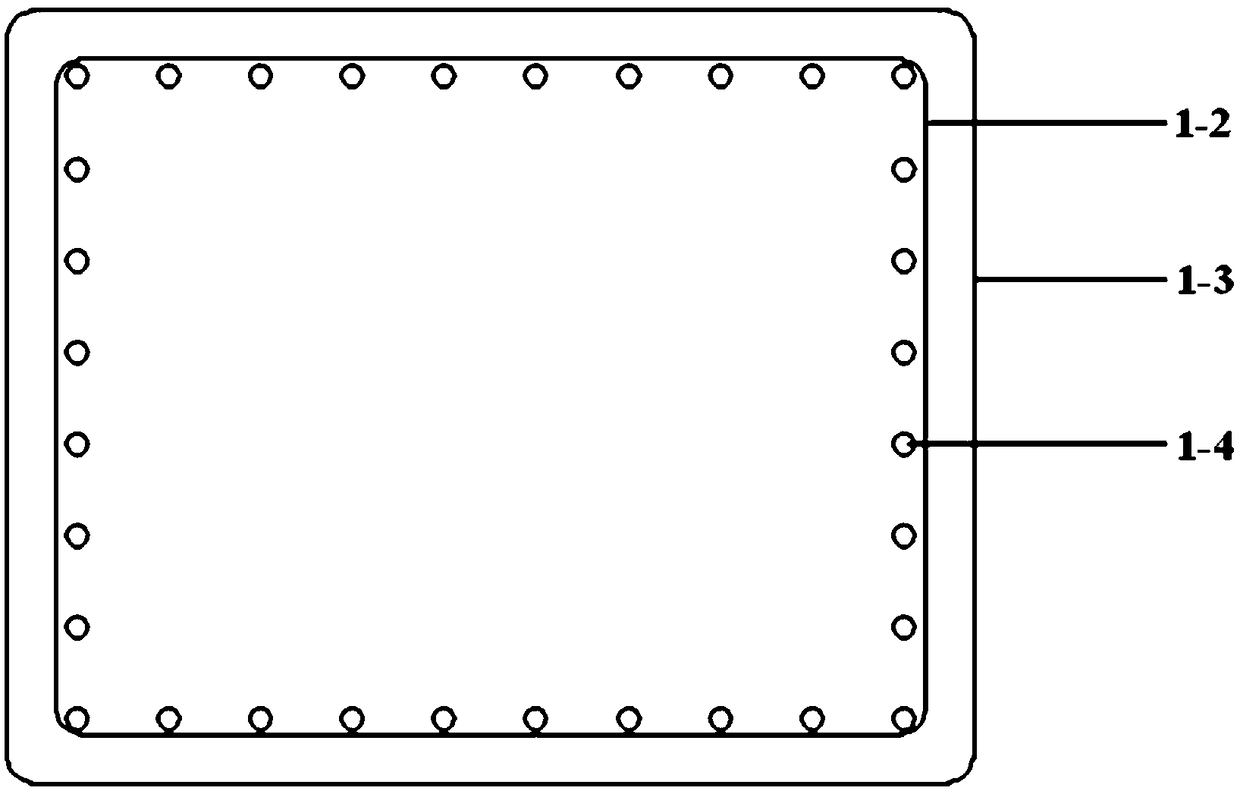

[0048] Use a punching machine to make holes at intervals of 2, 3, 4, 5, 6 cm and diameters of 5 and 10 mm on the bottom edge of the first container, pla...

Embodiment 2

[0055] Embodiment 2 Preparation of automatic electrophoresis gel staining device

[0056] 1. Materials

[0057] The liquid adding device adopts an automatic timing and quantitative liquid adding device (6 pump heads connected in parallel - 6 channels), and the liquid discharge device adopts a single pump head - single channel. 7 hoses; corresponding staining reagent bottles; punching machine; double-layer electrophoresis gel staining device (plastic material); shaking table; waste liquid tank.

[0058] 2. Method

[0059] There are 6 liquid filling holes on the edge of the upper cover of the double-layer electrophoresis gel staining device, and 6 hoses connected to the 6 pump head liquid filling devices extend into the first container and the second container of the double-layer electrophoresis gel staining device through the liquid filling holes on the top of the cover. Between the walls of the two containers, the 6 hoses at the other end of the liquid filling device are pla...

Embodiment 3

[0071] Example 3 Effect of automatic electrophoresis gel staining device and flat plate on electrophoresis gel staining

[0072] 1. Materials

[0073] Protein gel after two-dimensional gel electrophoresis (source: Bacillus thuringiensis cultured in inorganic salt system and triphenyltin pollution system; purchased from Guangdong Microbial Culture Collection Center; GIMCC1.817).

[0074] The basic method of obtaining the above-mentioned protein glue is as follows: the inorganic salt ion system (30mg L -1 K H 2 PO 4 , 20 mg L - 1 NaCl, 30 mg L -1 NH 4 Cl and 10 mg L -1 MgSO 4 ) cultured for 2 days and added triphenyltin pollutants (1mg L -1 ) The cells cultured for 2 days were washed and centrifuged to obtain the cells precipitated at the bottom, and the cells were resuspended in the lysate, and the cells were crushed with an ultrasonic breaker to obtain a protein solution. The protein solution was quantified and then subjected to two-dimensional gel electrophoresis ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com