Water leakage detection device for diaphragm gas meter movement and leakage detection method

A membrane gas meter and gas meter technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problem that the position of the leak point and the movement cannot be displayed accurately and intuitively Leak detection operation efficiency is not high, to achieve the effect of convenient leak detection operation, improve work efficiency, and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

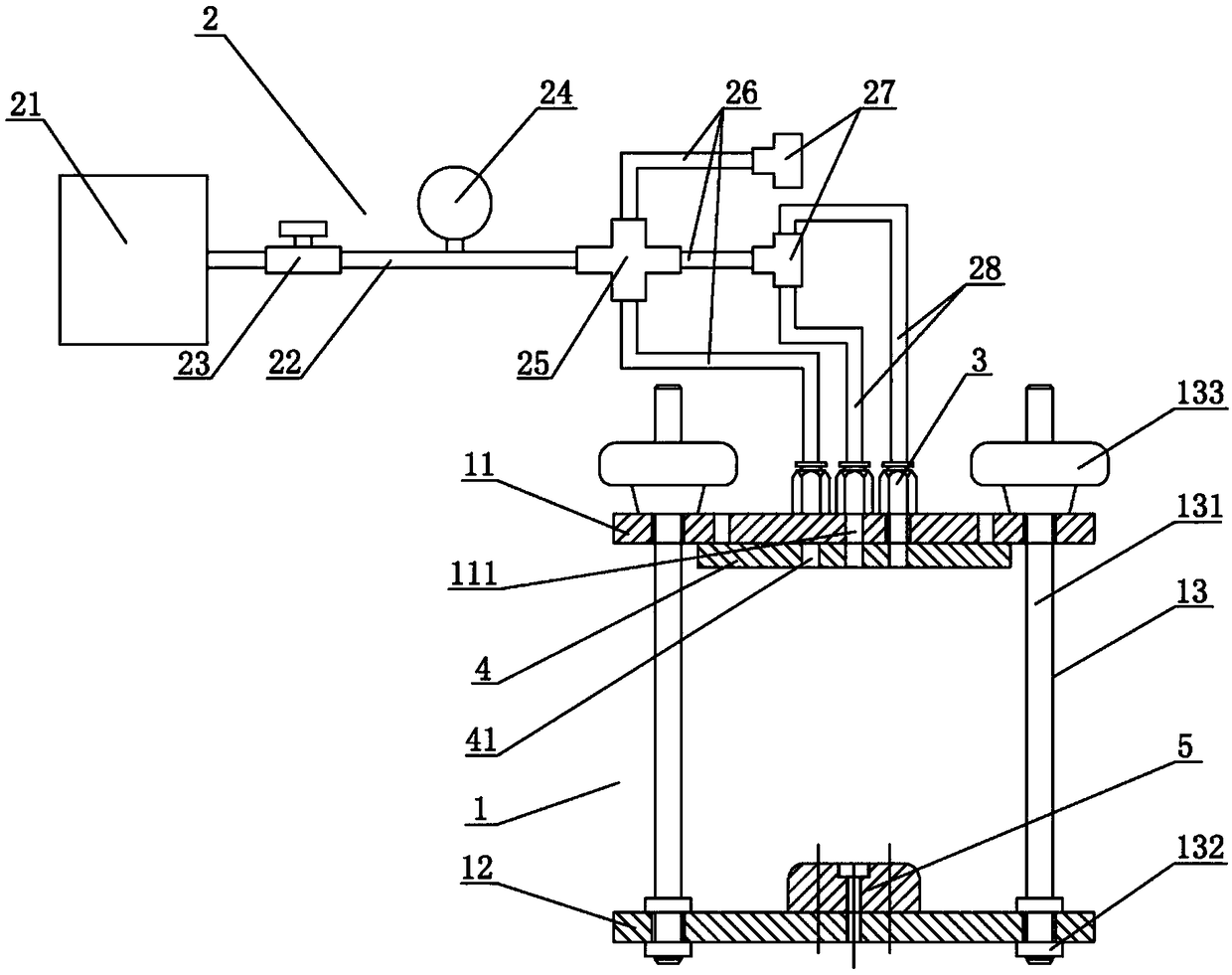

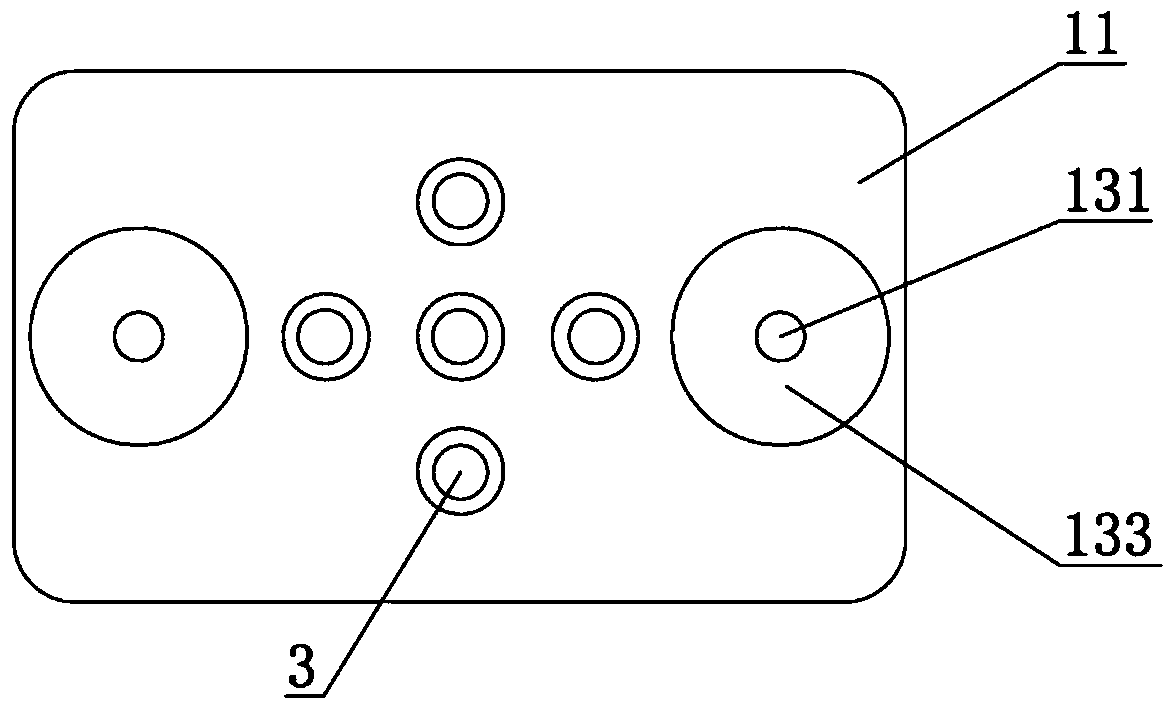

[0028] Concrete embodiment of the present invention is: as figure 2 As shown, a water-type leak detection device for a membrane gas meter movement includes a positioning bracket 1 for positioning and sealing the membrane gas meter movement and a control gas path 2 connected to the positioning bracket 1. The positioning bracket 1 is provided with a Each chamber of the movement communicates with an air pipe joint 3, and the air pipe joint 3 is connected with the control air circuit 2. After the leak detection device positions and seals the movement of the diaphragm gas meter through the positioning bracket 1, the positioning bracket 1 is placed in a transparent container filled with clear water, and the air is passed into each chamber of the movement through the control air circuit 2. High-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com