Offshore high-rise pile cap fan foundation and construction method

A technology of typhoons and high piles, applied in infrastructure engineering, construction, etc., can solve the problems of short effective construction time, high construction cost, and difficult construction, and achieve the effect of saving offshore operation time and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

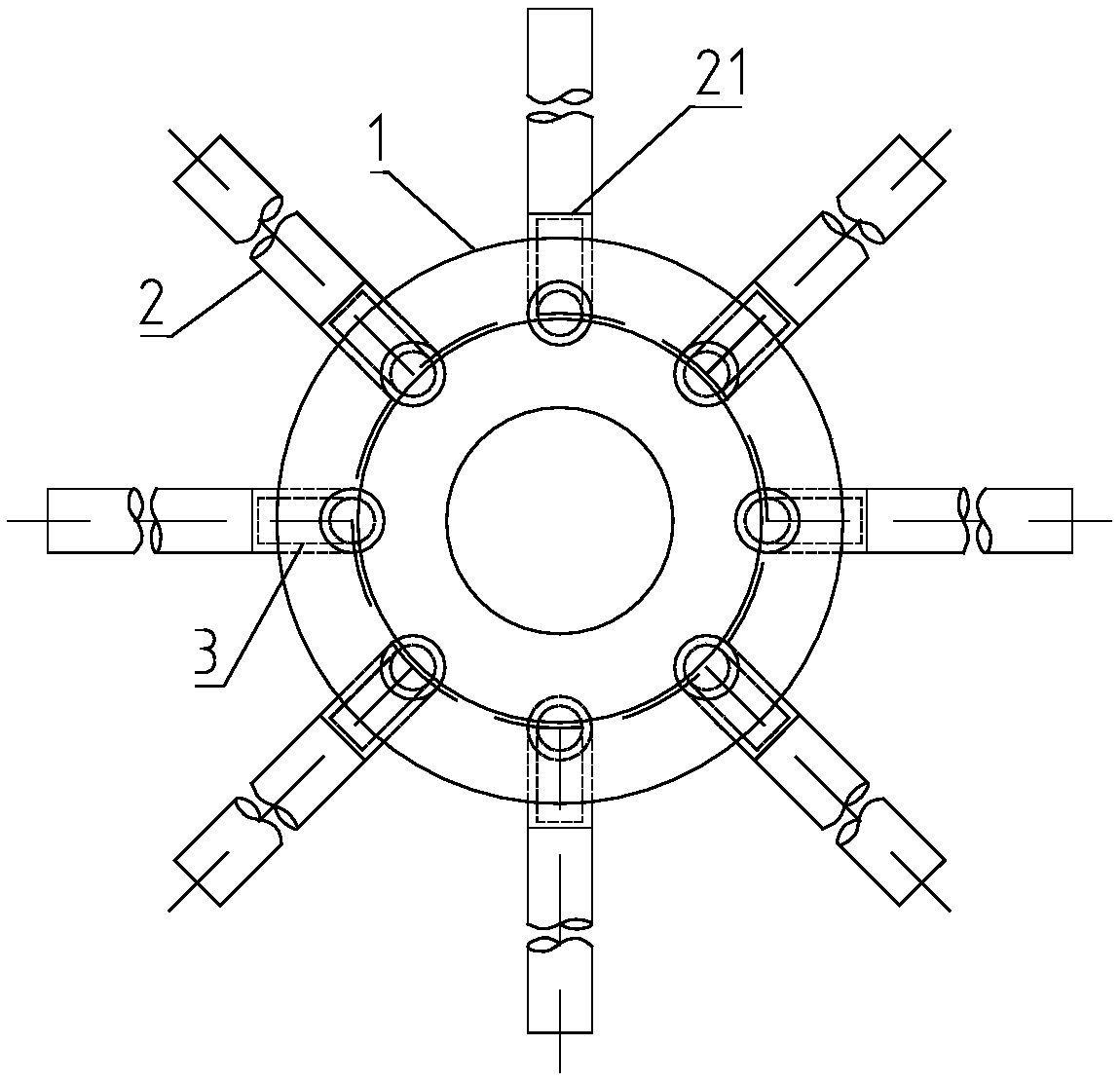

[0031] see Figure 1-3 , a high pile cap fan foundation, which includes a concrete cap 1 and a steel pipe pile (2) for supporting the concrete cap, the concrete cap 1 and the steel pipe pile 2 are connected by a steel pipe 3 The concrete cap 1 is a prefabricated component, the top end of the connecting steel pipe 3 is located inside the concrete cap 1, the bottom end of the connecting steel pipe 3 is located inside the top end of the steel pipe pile 2, and the The connecting steel pipe 3 and the steel pipe pile 2 are connected by grouting. The embedded anchor bolt 8 in the concrete cap 1 is used to connect the fan tower 9; the lower end of the steel pipe pile 2 is located below the mud surface, and the upper end is usually higher than the mean sea level (water surface).

[0032] The number of the steel pipe piles 2 is greater than or equal to 3, and all the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com