Full-automatic clothes conveying and clothes hanger separation and recycling method

A separation and recycling, fully automatic technology, applied in the direction of laundry room installation, transportation and packaging, folding thin materials, etc., can solve the problems of low folding efficiency and no effective solution, and achieve the effect of rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

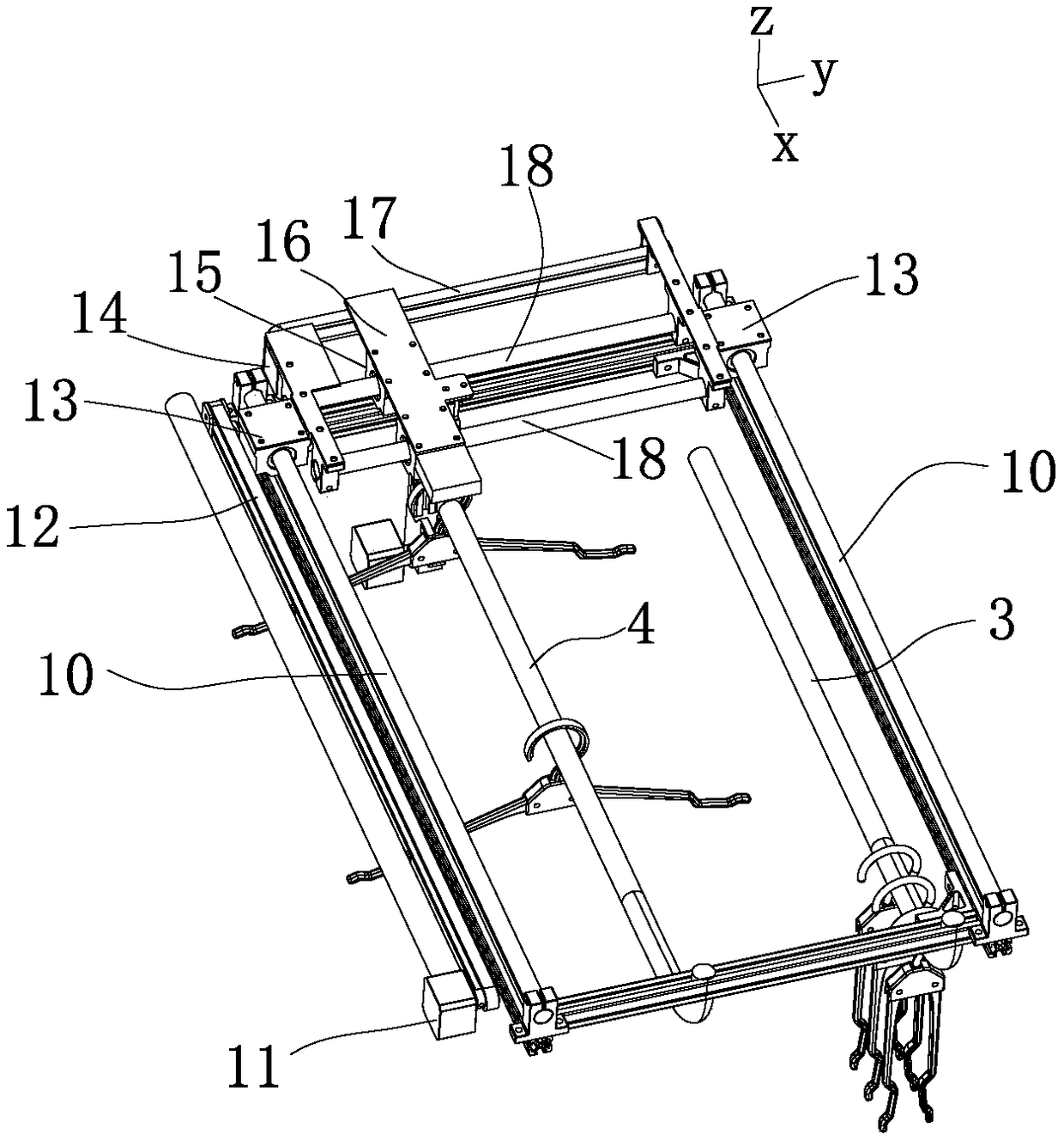

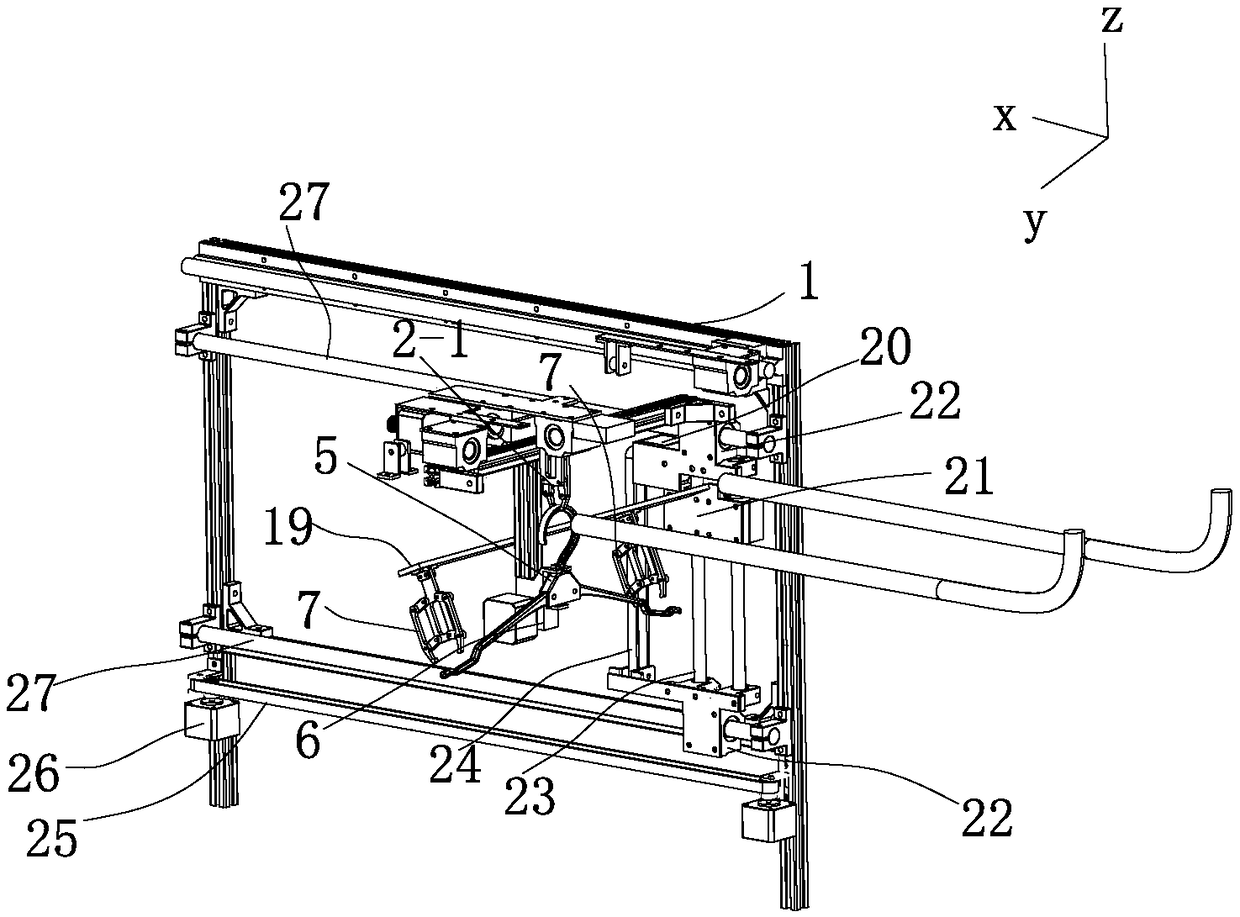

[0030] Figure 1-Figure 2 As shown, the clothes folding machine includes a control module, a conveying system and a hanger recovery system. The conveying system and the hanger recovery system are arranged on the top frame 2, including a folded clothes hanger 5, a first clamping claw 2-1, and an X-axis driving device. and Y-axis drive unit one.

[0031] X-axis driving device-includes X-axis slide bar-10, X-axis slide block-13, X-axis transmission belt-12, X-axis slide bar-10 is arranged on top frame 2, and X-axis slide block-13 is set on X-axis On the slide bar-10, the X-axis slide block-13 is linked with the X-axis transmission belt-12, and the first motor 11 and the belt pulley drive the X-axis transmission belt-12 to move.

[0032] Y-axis driving device-includes Y-axis slide bar-18, Y-axis slide block-15, Y-axis transmission belt-17, Y-axis slide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com