Technology for producing medium element fertilizer by using phosphogypsum

A technology of phosphogypsum and elements, which is applied in the field of using phosphogypsum to produce medium-element fertilizers, can solve the problems of unfavorable product solubility and destruction of nutrients, and achieve the effects of reducing ammonia volatilization, improving soil, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

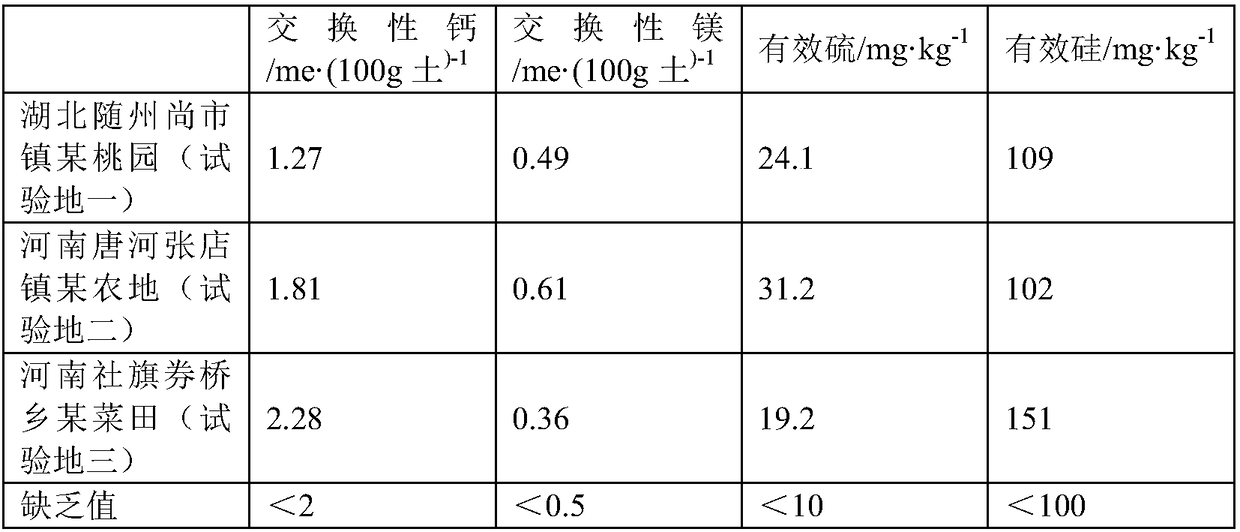

Examples

Embodiment 1

[0023] A process for producing medium-weight element fertilizers using phosphogypsum, which includes the following steps: firstly pretreat the phosphogypsum, and the pretreated raw materials need to be sampled before being put into use. In order to facilitate granulation and ensure the appearance of the product, it is necessary to It is mixed with soil conditioner in a certain proportion, and becomes granular fertilizer after being crushed and granulated, and then the product is obtained through primary drying, primary cooling, secondary drying, and secondary cooling. Among them, the free water in phosphogypsum after pretreatment The specific gravity is 12% to 15%. The granular fertilizer is heated to 75°C to 85°C during the first drying, and the proportion of free water in the granular fertilizer is reduced to 10% to 13%. After the first cooling, the temperature of the granular fertilizer is reduced to 65°C. During the first drying, the granular fertilizer is heated to 75°C to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com