Stamp-pad ink sponge assembly as well as seal assembly and stamping machine applying stamp-pad ink sponge assembly

A technology of stamping machine and ink, applied in printing, stamping and other directions, can solve the problems of uneven ink, difficult process, large flow, etc., and achieve the effect of uniform oil replenishment, uniform pressure balance, and clear and uniform stamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

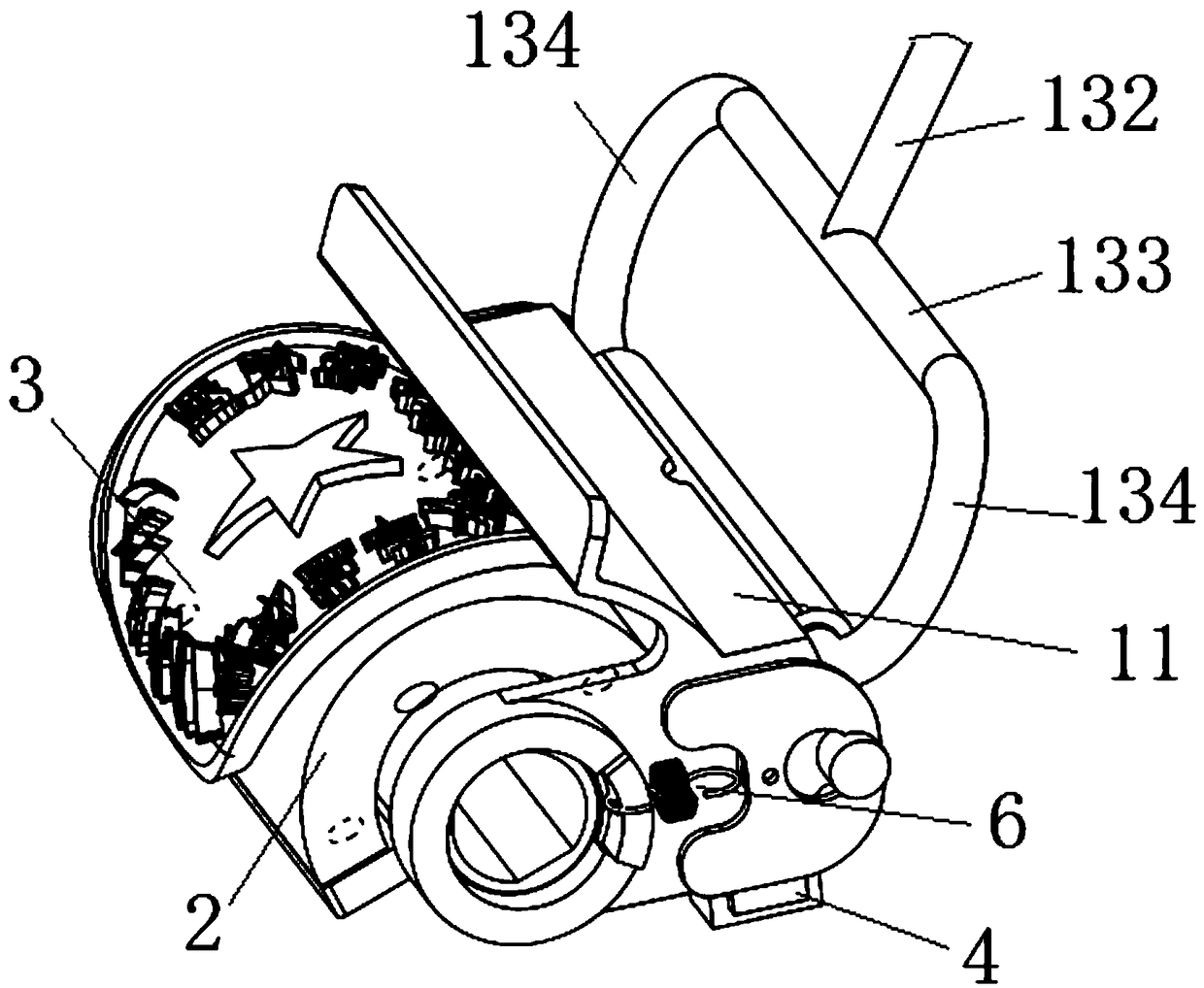

[0038] Such as figure 1 , 3 As shown, a printing ink sponge assembly, which is used on the stamping machine, it includes:

[0039] cavity 11;

[0040] Printing ink sponge 12, described printing ink sponge 12 is supported on the cavity 11;

[0041]The ink replenishment assembly for replenishing ink to the ink sponge 12 in the cavity 11, the ink replenishment assembly includes a hose 13 for conveying ink, and the hose 13 has an output pipe section 131 arranged in the cavity 11. There is a critical pressure in the ink passage for conveying ink in the output pipe section 131, and there is at least one set on the outlet pipe section 131 that communicates with the ink passage and is in a closed state and in the ink passage when the pressure in the ink passage is less than the critical pressure. When the pressure is greater than or equal to the critical pressure, the hole 1311 is in an open state, thereby replenishing ink to the ink sponge 12 .

[0042] In this embodiment, at lea...

Embodiment 2

[0049] Such as figure 2 , 3 As shown, a stamp assembly, which includes:

[0050] A stamp holder 2 that can be driven to rotate;

[0051] A stamp 3 mounted on the stamp holder 2;

[0052] The printing ink sponge assembly in the first embodiment, the printing ink sponge assembly also includes the printing ink sponge support 14, the printing ink sponge support 14 is installed on the stamp support 2, the cavity 11 is installed on the printing ink sponge support 14, and the stamp support 2 rotates During the process, at least a part of the ink sponge 12 is in contact with the stamp 3, so that the ink sponge 12 provides ink to the stamp.

[0053] Such as image 3 As shown, a limit mechanism is provided between the cavity 11 and the ink sponge support 14, so that during the rotation of the stamp support 2, the limit mechanism makes the non-protruding parts of the ink sponge 12 and the stamp 3 Partially out of contact with and making the ink sponge 12 in contact with the raised ...

Embodiment 3

[0060] Such as Figure 4 As shown, a stamping machine, it includes:

[0061] The stamp shaft 5 driven to rotate;

[0062] In the stamp assembly in the second embodiment, the stamp support 2 in the stamp assembly is installed on the stamp shaft 5, and the stamp support 2 is driven to rotate by driving the stamp shaft 5 to rotate.

[0063] When the paper enters the stamping machine, the paper-feeding stepping motor 10 drives the rubber roller 20 to rotate, and the paper enters the meshing part of the rubber roller 20, and continues to feed the paper. When the paper reaches the designated stamping position, the stamp stepping motor 30 drives the stamp shaft 5 to rotate , the stamp shaft 5 will drive the stamp 3 to rotate once. During this one-round rotation, the stamp 3 will mesh with the ink sponge 12 once, and the ink will be transferred to the surface of the raised part of the stamp 3 when meshing, and then the stamp 3 will mesh with the paper. The ink is transferred from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com