Compression system based on gear occlusion transmission

A compression system and gear technology, applied in presses, recycling technology, plastic recycling, etc., can solve the problem of high cost, and achieve the effects of convenient assembly and disassembly, ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

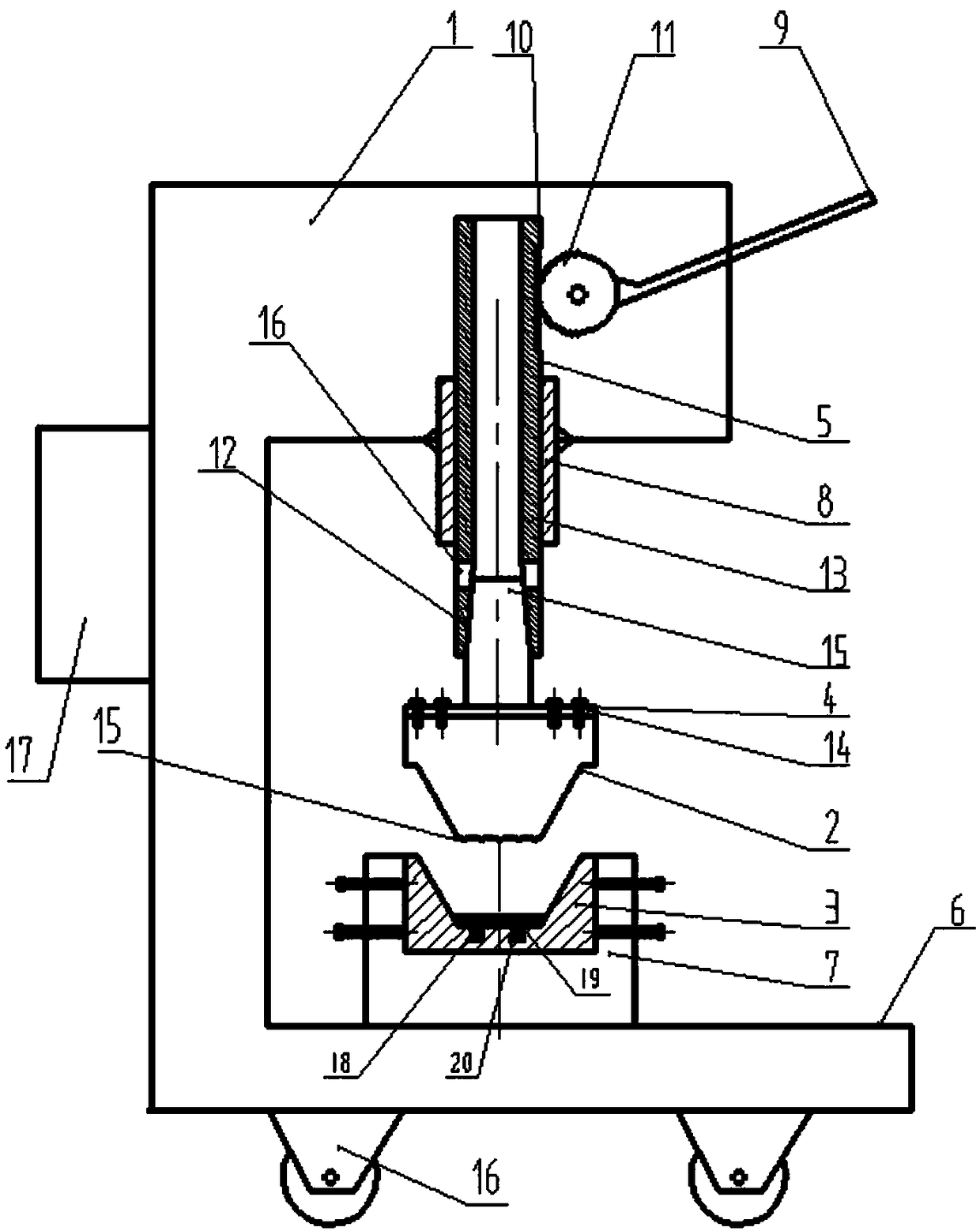

[0016] Such as figure 1 A compression system based on gear meshing transmission is shown, including a waste compression support frame 1, a waste compression upper mold 2, a waste compression lower mold 3, an upper mold connector 4, a waste compression lifting assembly 5 and a gear pressing rod assembly 9, The waste material compression support frame 1 is provided with an operation table 6, and the operation table 6 is provided with a lower mold installation bayonet 7, and the waste material compression lower mold 3 is installed in the lower mold installation bayonet 7, and the waste material compression upper mold 3 passes through The upper mold connector 4 is assembled on the waste compression lifting assembly 5, the waste compression lifting assembly 5 is arranged in the lifting slide 8 on the top of the waste compression support frame 1, and the waste compression lifting assembly 5 is provided with lifting rack teeth 10 , the gear press bar assembly 9 is installed on the to...

Embodiment 2

[0021] Such as figure 1 Shown is a compression system based on gear meshing transmission. On the basis of Embodiment 1, the upper mold connector 4 includes a connecting plate 14 and a connecting shaft 15, and one end of the connecting shaft 15 is welded to the connecting plate 14 The other end is conical and installed in the inner conical cylinder 12 of the lifting cylinder 13, and the connecting plate 14 is connected with the upper mold 2 for crimping the scrap by bolts. When needing to change waste material crimping upper mold 2, use wedge to insert in the wedge groove 16 on the lifting cylinder 13 and beat, upper mold connector 4 just can come off. A sliding wheel 16 is provided at the bottom of the waste compression frame 1 to facilitate the movement of the waste compression device, and a push handle frame 17 is provided outside the waste compression frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com