A mortar feeder with mixing and water inlet

A feeder and mortar technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of manual water addition, slow mortar formation, slow mortar penetration, etc., and achieve the goal of improving installation efficiency and speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

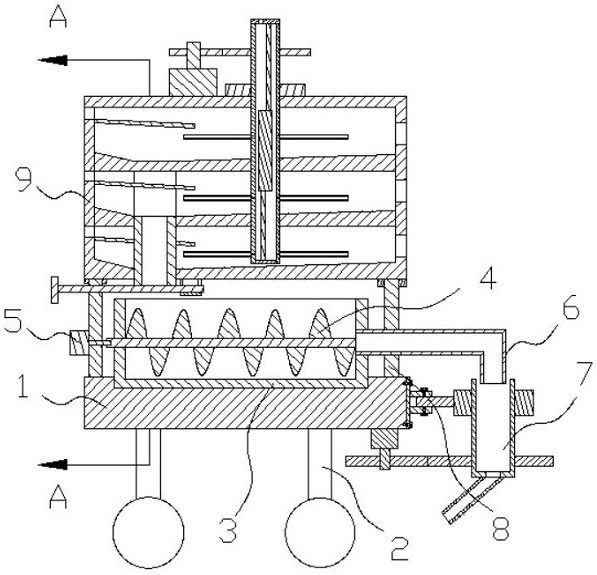

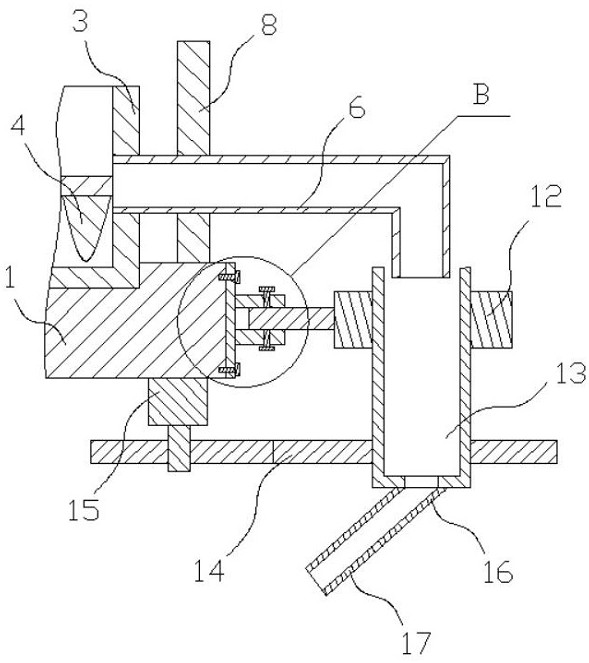

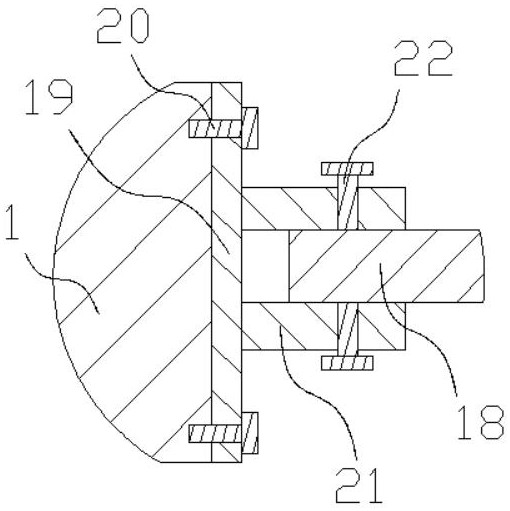

[0035] like Figure 1-Figure 7 As shown, the specific structure of the present invention is: a mixing and water inlet integrated mortar feeder, which includes a support base 1 and a walking device 2, and the support base 1 is provided with a feeding device and support plates arranged on the left and right sides of the feeding device 8. The support plate 8 is provided with a pulping device 9, and the right support plate 8 is provided with a conveying pipe communicating with the feeding device. The pulping device 9 includes a pulping box connected to the support plate 8 25. The slurry forming box 25 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com