Automatic screw gun

A screw and automatic technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low installation efficiency and safety hazards, and achieve the effect of avoiding safety hazards and improving nailing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

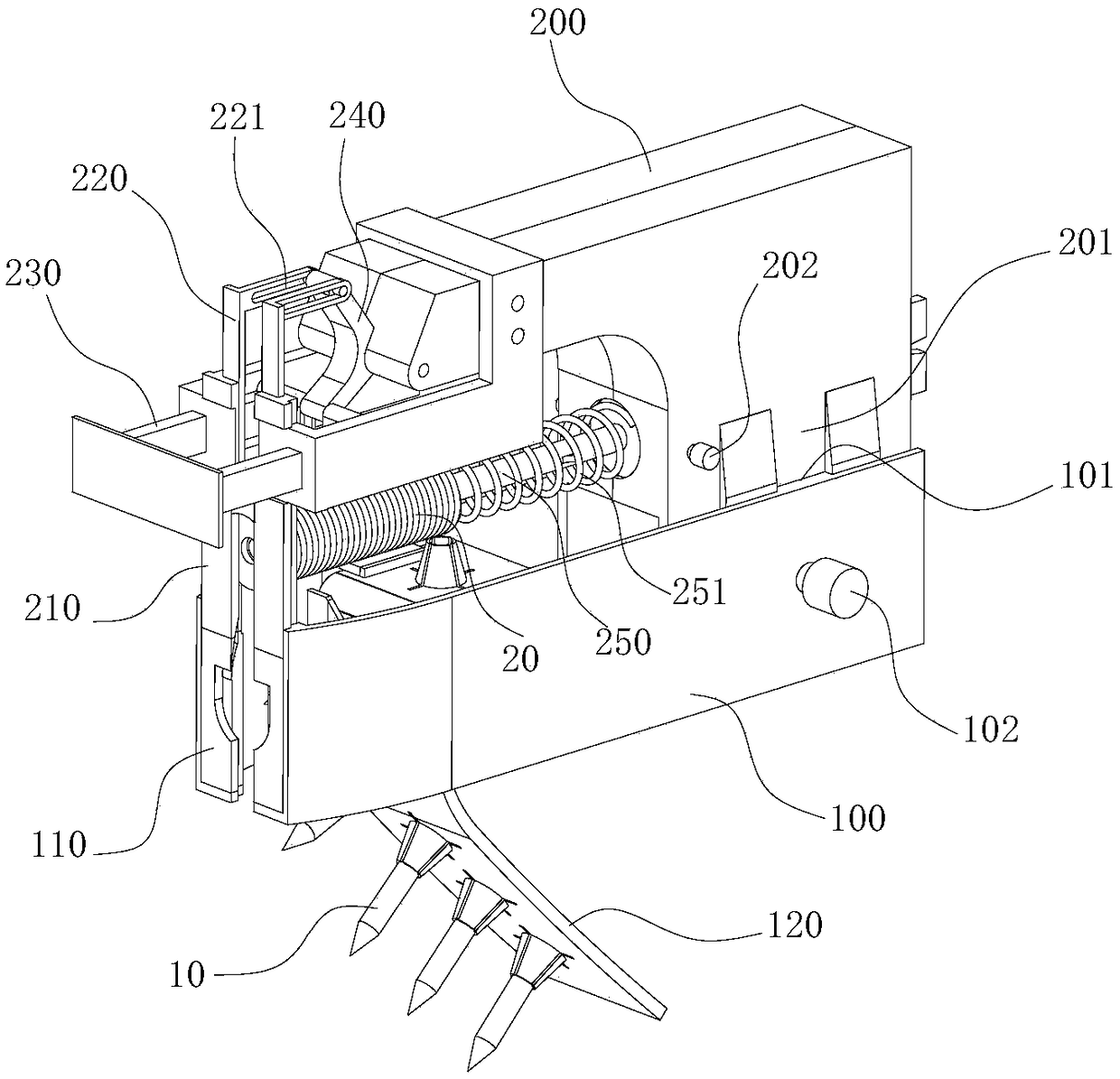

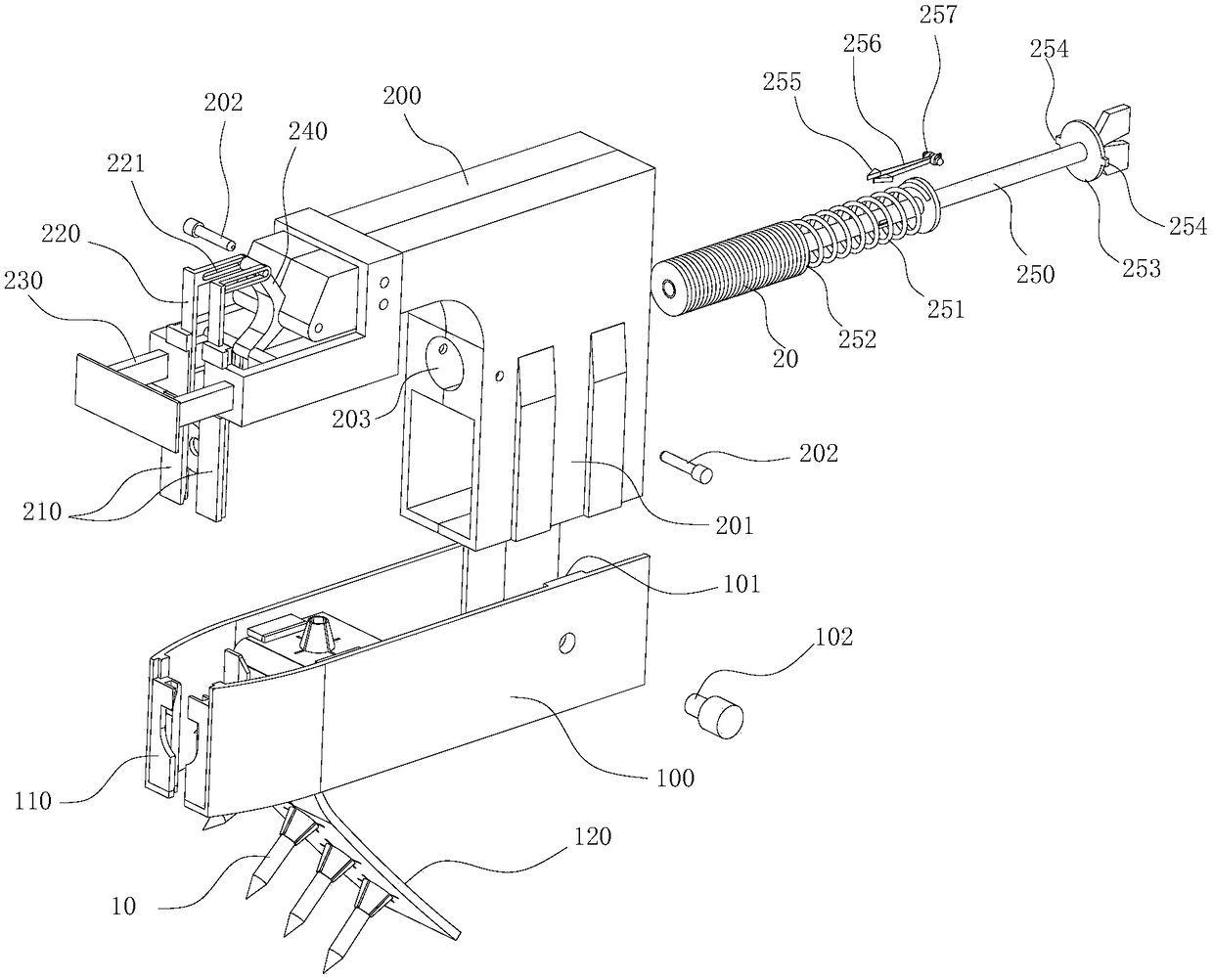

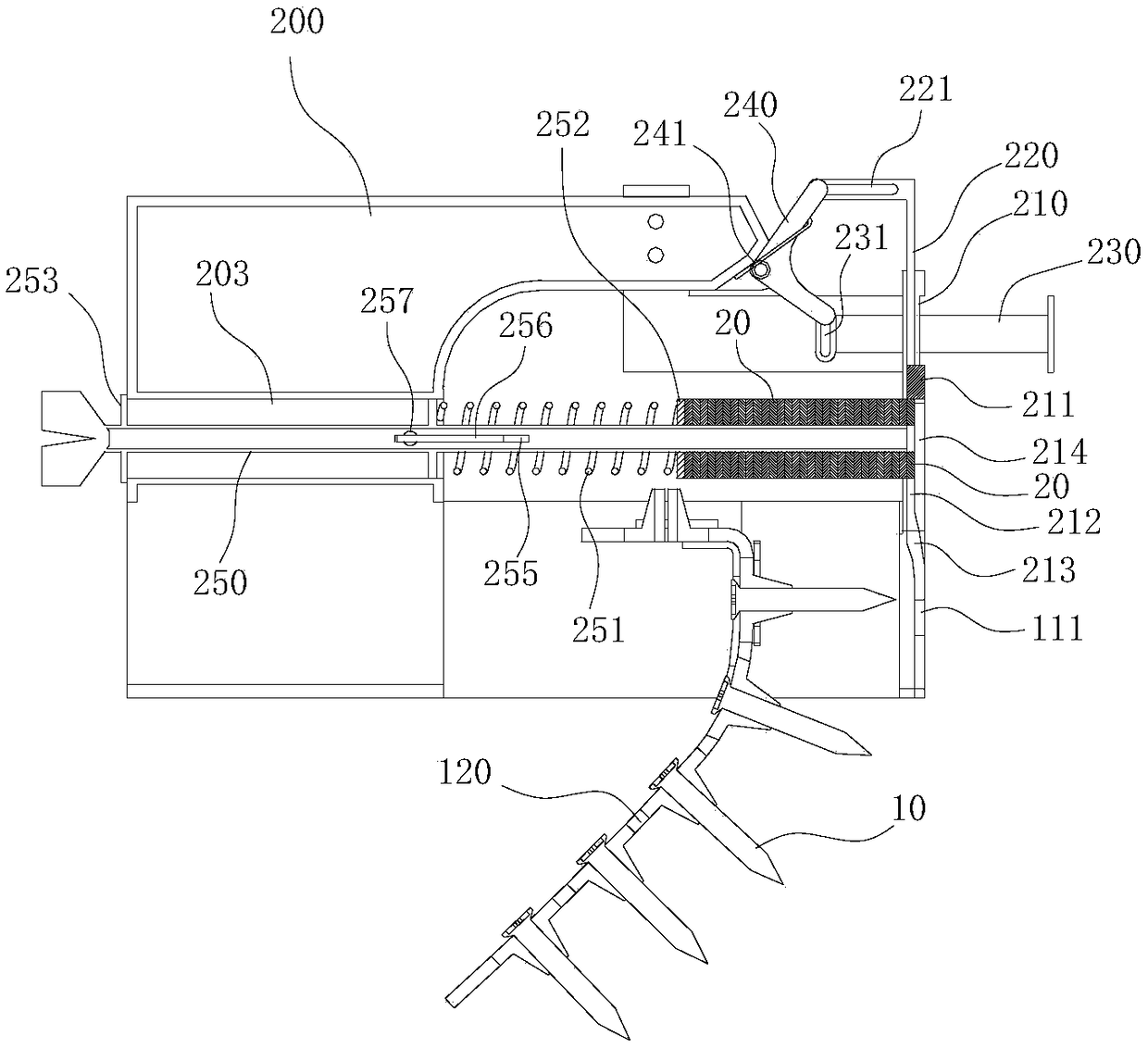

[0025] combine Figure 1 to Figure 9 , the present invention is further described:

[0026] In order to make the objects and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

[0027] It should be noted that: in the expression of the present invention, the expressions of "front", "rear" and other directions are based on the general understanding of the structure of the nail gun by those of ordinary skill in the art, that is, the nail gun's The end where the gun head is located is the front, and vice versa is the rear; the expression of the "vertical" and "horizontal" directions is based on the operator's normal posture when holding the automatic screw gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com