Pressing device for automatically pressing cover plate

A press-fitting and capping technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inaccurate cover plate alignment, low production efficiency, flanging motor, etc., saving labor and improving production efficiency , to avoid the effect of flanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

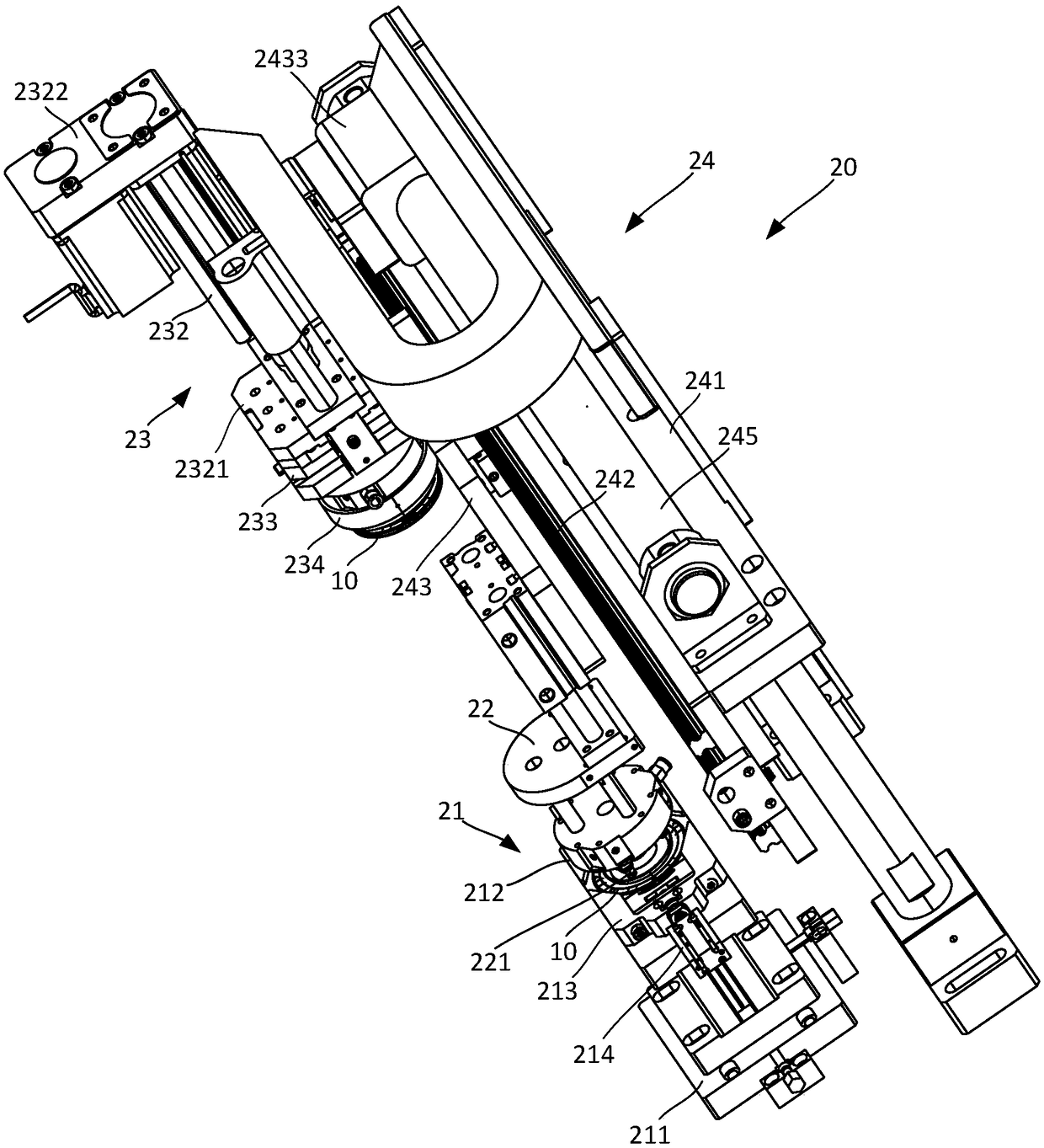

[0040] refer to figure 1 , The present invention provides a press-fitting equipment for automatic cover plate, which is used to precisely press-fit the cover plate into the sealing groove of the motor gearbox, so as to realize the waterproof and sealing of the motor. Moreover, the press-fitting equipment of the present invention can realize the full automation of the press-fitting process, save labor and improve production efficiency. Utilizing the accuracy of mechanical equipment, the problems caused by inaccurate manual alignment are greatly reduced. The press-fitting equipment for the automatic cover plate of the present invention will be described below in conjunction with the accompanying drawings.

[0041] refer to figure 1 , shows the front view of the press-fitting equipment for the automatic cover plate of the present invention. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com