Waxing device for production of wood-plastic floor

A wood-plastic floor, the technology on the other side is applied to the device for coating liquid on the surface, the machine tool suitable for grinding the plane of the workpiece, the grinder and other directions, which can solve the problems of heavy workload, cumbersome and laborious waxing process, etc. To achieve the effect of convenient waxing and speeding up waxing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

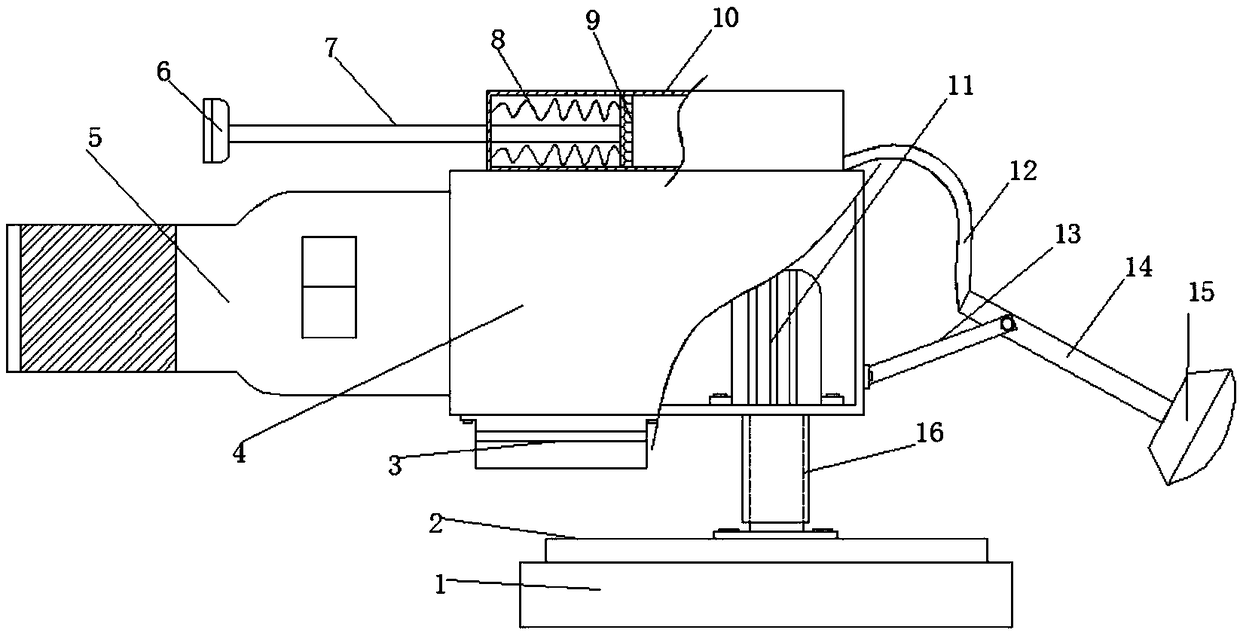

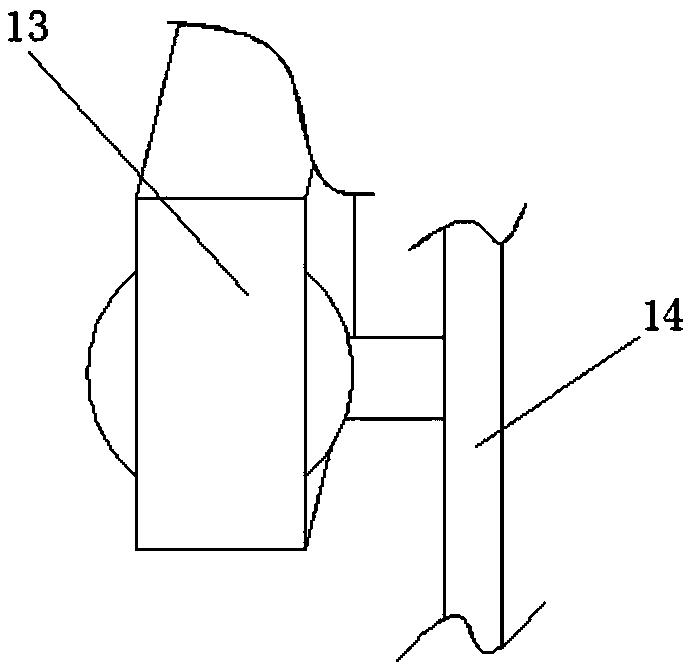

[0017] Reference Figure 1-2 , A waxing device for wood-plastic floor production, comprising a housing 4, one side of the outer wall of the housing 4 is fixed with a handle 5 by screws, and the bottom end of the other side of the outer wall of the housing 4 is fixed with an inclined support by screws The rod 13 is provided with a ball hinge at the top end of the support rod 13, and the support rod 13 is rotatably connected with a T-shaped structure of the feed pipe 14 through the ball hinge. The outer wall of the top end of the housing 4 is fixed with a sleeve 10 and the sleeve 10 One side of the outer wall is provided with a first opening,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com