Novel double-layer filter material filtration tank applied to oil field sewage treatment

A technology of oilfield sewage and double-layer filter material, which is applied in the direction of loose filter material filter, filter separation, gravity filter, etc., can solve the problems of easy damage of mechanical seal device, inability to discharge suspended solids, and influence on equipment use, etc., to achieve Reduce vibration damage, facilitate full use, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

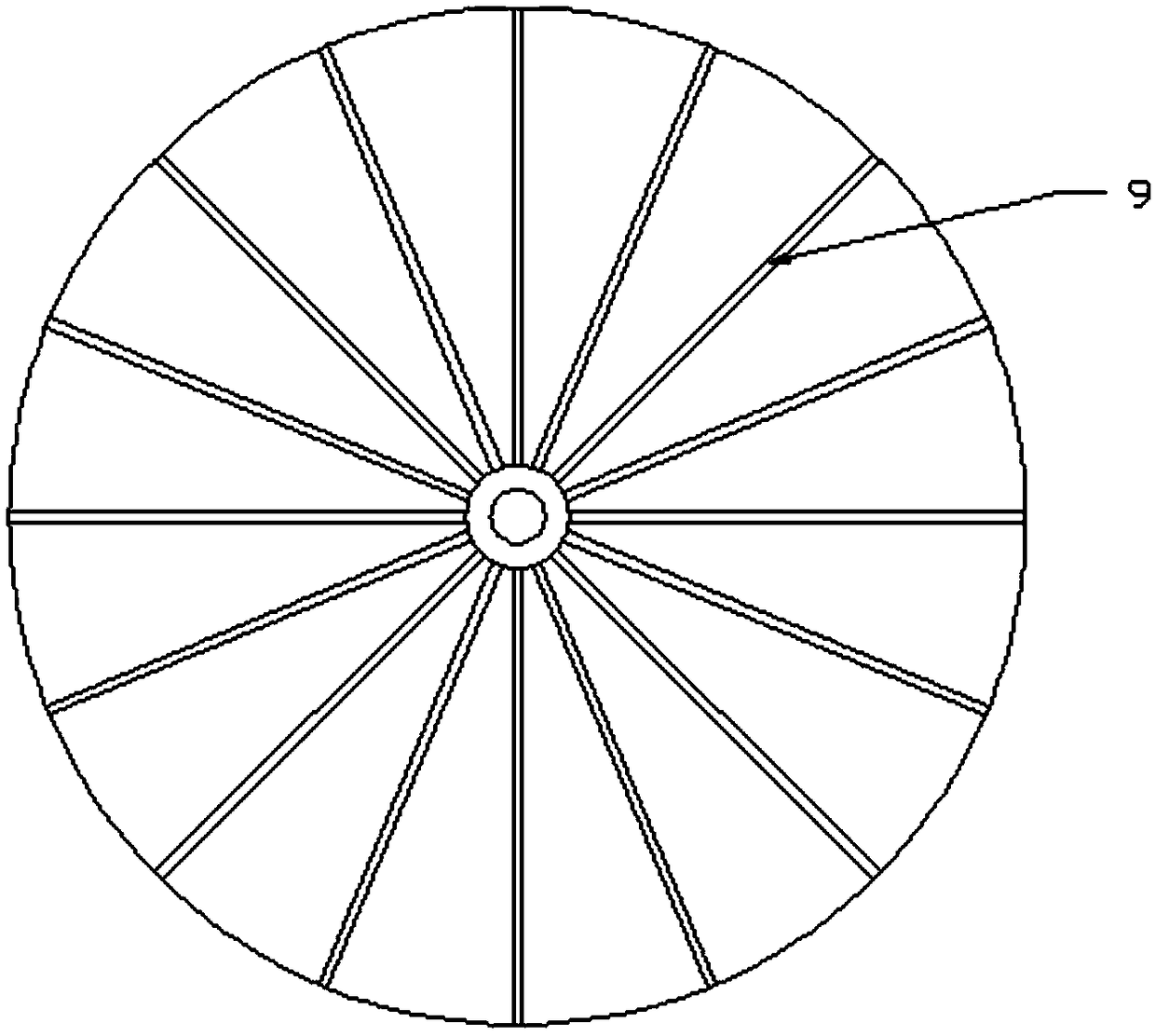

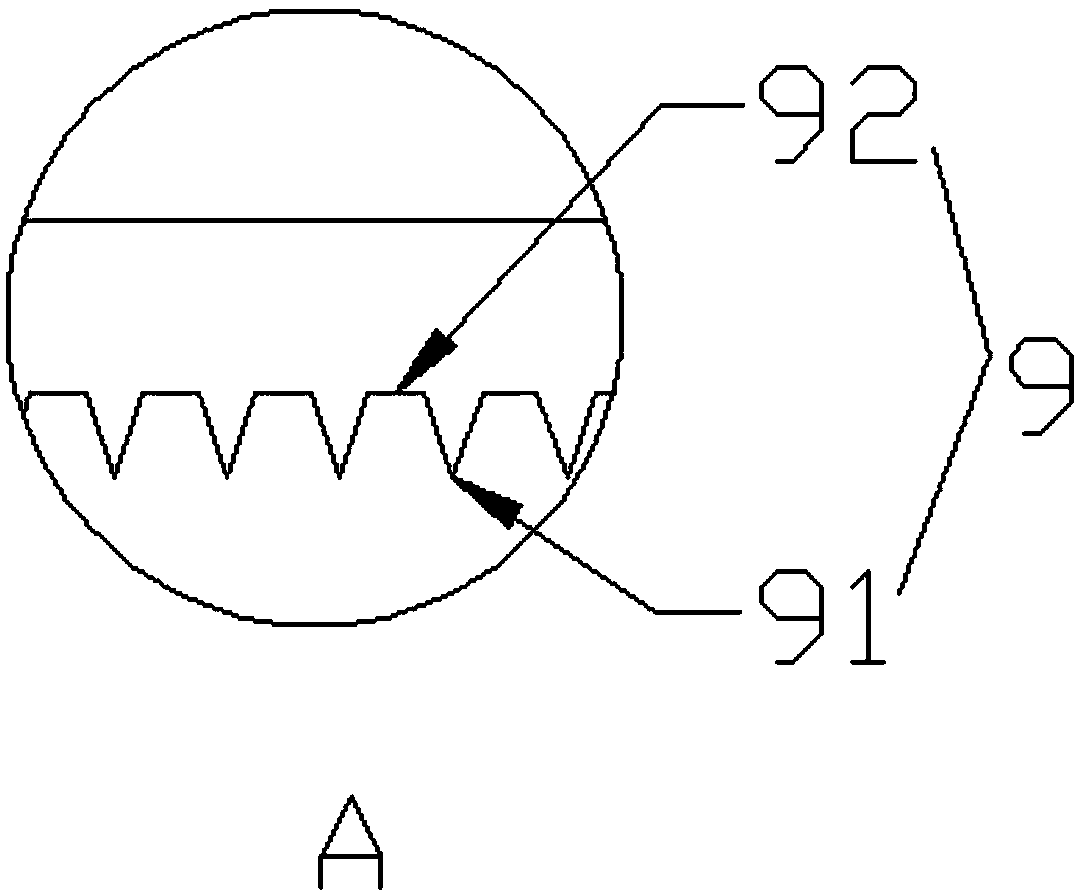

[0024] Please refer to the attached Figure 1-8 , a new double-layer filter material filter tank applied to oilfield sewage treatment, the device includes a tank body, a water distribution device, a stirring device and a water collection device 16, and the tank body includes an upper head 19, a cylinder body 17, The lower head 15 and the skirt 13, the upper end of the upper head 19 communicates with a water inlet chamber 3, the side wall of the water inlet chamber communicates with a filter inlet pipe 21, and the water distribution device includes a water distribution substrate 6 and the water distribution sieve plate 7, the water distribution sieve plate 6 is uniformly provided with water distribution holes, the water distribution sieve plate 7 is a screen-like structure, and the edge of the water distribution base plate 6 is fixedly connected to the head of the tank body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com