Brush hairs of toothbrush

A technology of bristles and toothbrushes, which is applied in the field of manufacturing bristles and bristle moulds, which can solve the problems of variable crooked curls and heavy force on toothbrush bristles, and achieve the effect of reducing crooked crimps and high-efficiency cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

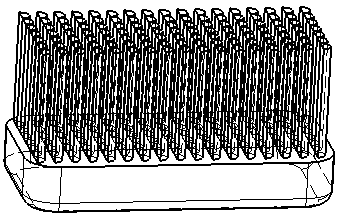

[0016] figure 1 , figure 2 , image 3 , Figure 4 It is a structural view of toothbrush bristles in the prior art, showing a "one"-shaped plane on the end face of the bristle array, and a concave arc, wave, and zigzag surface.

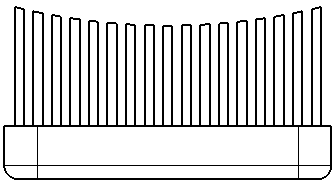

[0017] Figure 5 It is an embodiment of the present invention. In the toothbrush bristle array structure with long rows and short columns, the center column is empty, and two symmetrical bristle arrays are distributed. All the bristles are formed with equal lengths, forming a "one" shape. flat.

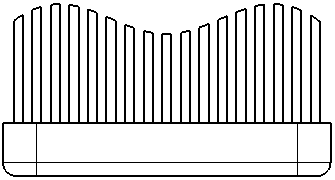

[0018] Figure 6 It is another embodiment of the present invention. The bristles arranged from the two ends of the long row to the empty rows in the center are shortened successively, and the end faces of the bristles are formed into a "V"-shaped slope through cutting or injection molding. The included angle of the "V" shape is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com