Milling machine for garment template

A milling and template technology, applied in the field of garment processing, can solve the problems of affecting product flatness and aesthetics, affecting product quality, and quality insecurity, etc., to solve the problem of excessive dependence on high skills, simplify complex processes, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

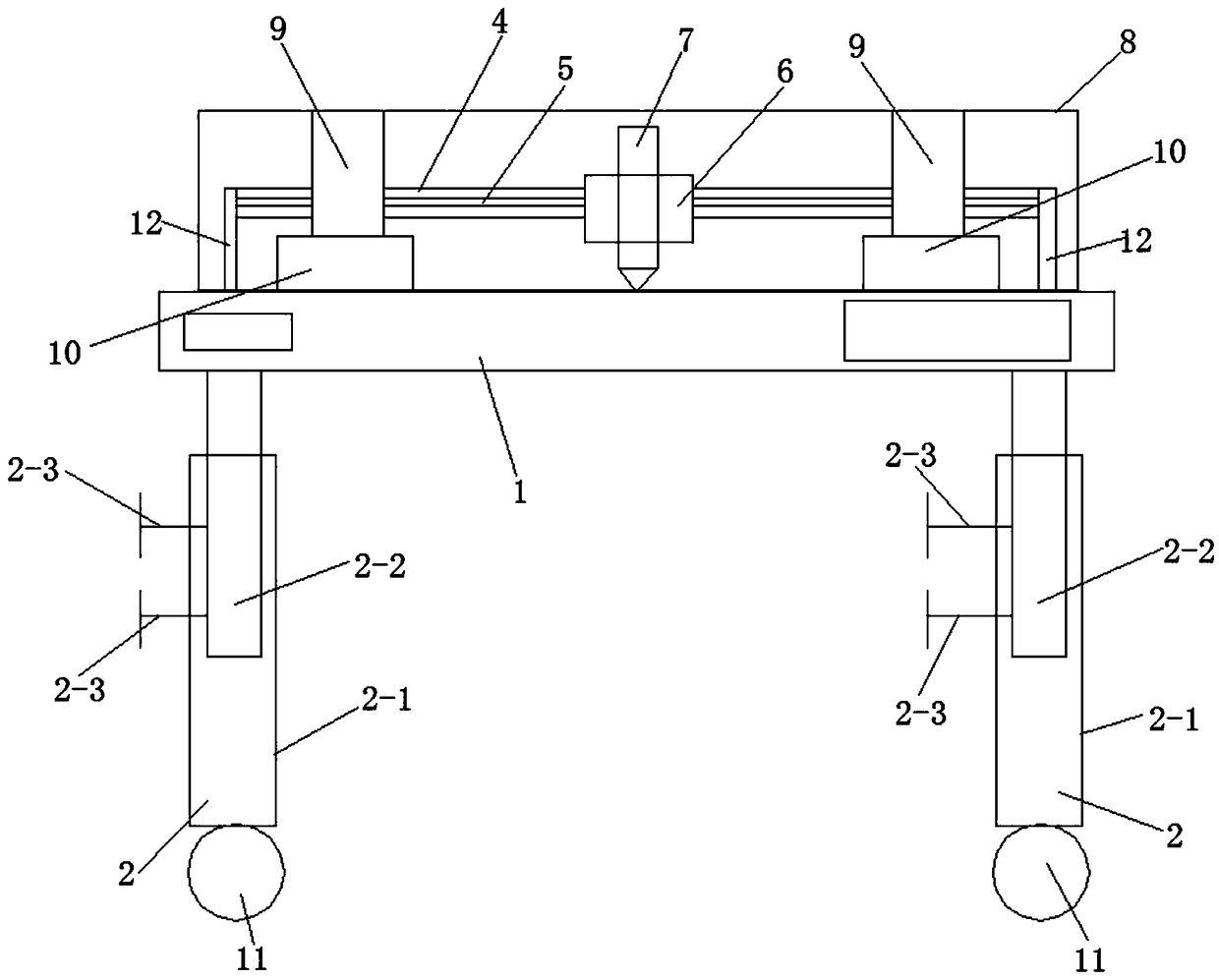

[0033] A milling and cutting machine for making garment templates, comprising a workbench 1 on which a milling template is arranged, height-adjustable outriggers 2 are arranged under the workbench 1, and opposite sides of the workbench 1 are respectively There is a guide rail A3, a crossbeam support 4 is provided between the two guide rails A3, a guide rail B5 is provided on the crossbeam support 4, a positioner 6 is provided on the guide rail B5, a milling head 7 is provided on the positioner 6, and the workbench 1 A set of pressing plate mechanisms are respectively provided at opposite ends. The positioner 6 can move along the guide rail B5. Locator 6 adopts existing clothing cutting locator. Support leg 2 comprises sleeve 2-1, and the bottom of sleeve 2-1 is provided with roller 11, and telescopic pole 2-2 is arranged in sleeve 2-1, and the distance between sleeve 2-1 and telescopic pole 2-2 There are positioning pins 2-3 between them. At least two positioning pins 2-3 a...

Embodiment 2

[0035] A milling and cutting machine for making garment templates, comprising a workbench 1 on which a milling template is arranged, height-adjustable outriggers 2 are arranged under the workbench 1, and opposite sides of the workbench 1 are respectively There is a guide rail A3, a crossbeam support 4 is provided between the two guide rails A3, a guide rail B5 is provided on the crossbeam support 4, a positioner 6 is provided on the guide rail B5, a milling head 7 is provided on the positioner 6, and the workbench 1 A set of pressing plate mechanisms are respectively provided at opposite ends. The positioner 6 can move along the guide rail B5. Locator 6 adopts existing clothing cutting locator. Support leg 2 comprises sleeve 2-1, and the bottom of sleeve 2-1 is provided with roller 11, and telescopic pole 2-2 is arranged in sleeve 2-1, and the distance between sleeve 2-1 and telescopic pole 2-2 There are positioning pins 2-3 between them. At least two positioning pins 2-3 a...

Embodiment 3

[0037] A milling and cutting machine for making garment templates, comprising a workbench 1 on which a milling template is arranged, height-adjustable outriggers 2 are arranged under the workbench 1, and opposite sides of the workbench 1 are respectively There is a guide rail A3, a crossbeam support 4 is provided between the two guide rails A3, a guide rail B5 is provided on the crossbeam support 4, a positioner 6 is provided on the guide rail B5, a milling head 7 is provided on the positioner 6, and the workbench 1 A set of pressing plate mechanisms are respectively provided at opposite ends. The positioner 6 can move along the guide rail B5. Locator 6 adopts existing clothing cutting locator. Each set of platen mechanism includes an inverted U-shaped support 8, at least two pressing rods 9 are arranged on the cross bar of the supporting frame 8, and pressing blocks 10 are arranged on the pressing rods 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com