An agricultural bean beaning device

An agricultural and mounting board technology, applied in the fields of agriculture, agricultural machinery and implements, applications, etc., can solve the problems of low efficiency and large labor, and achieve the effect of improving efficiency and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

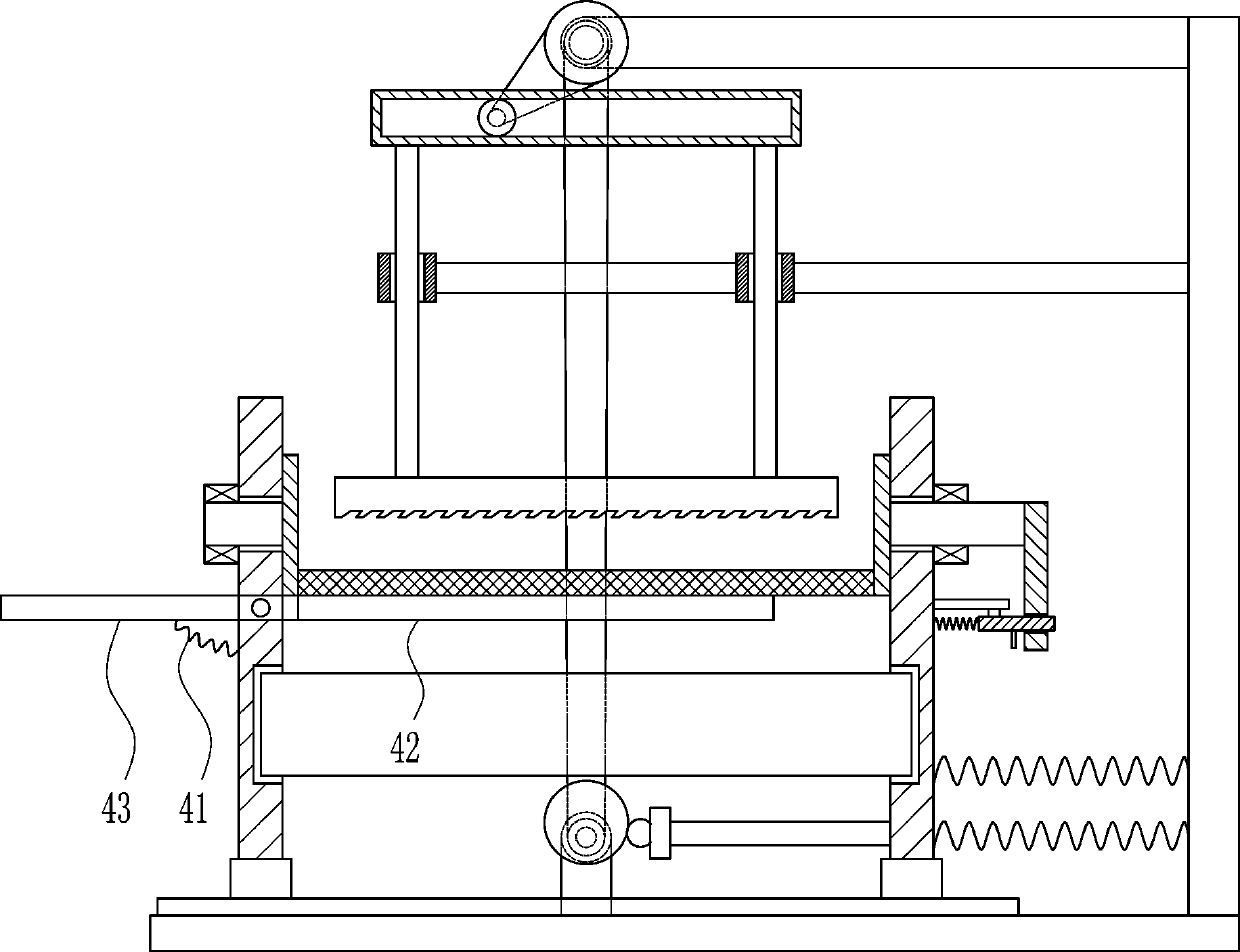

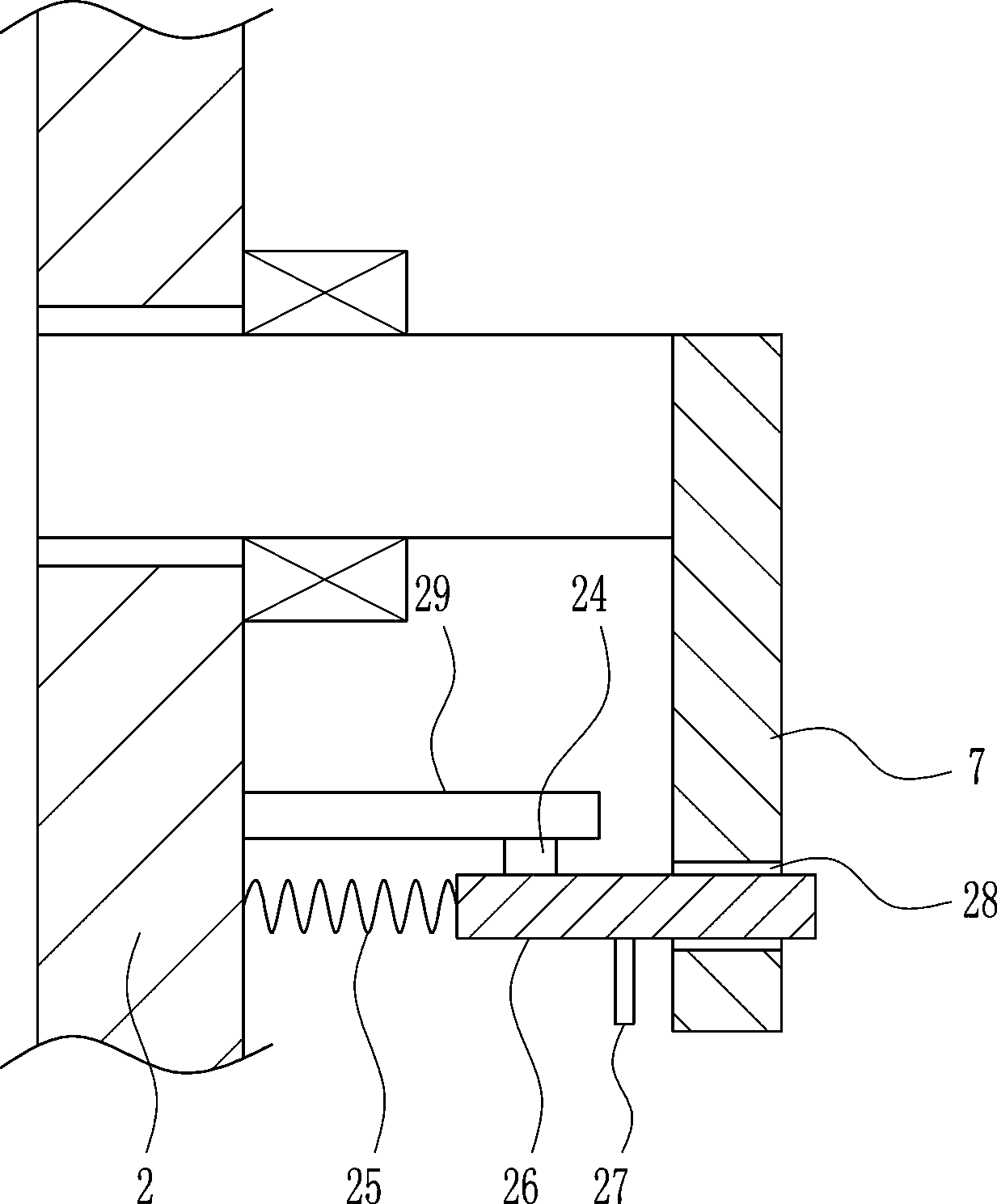

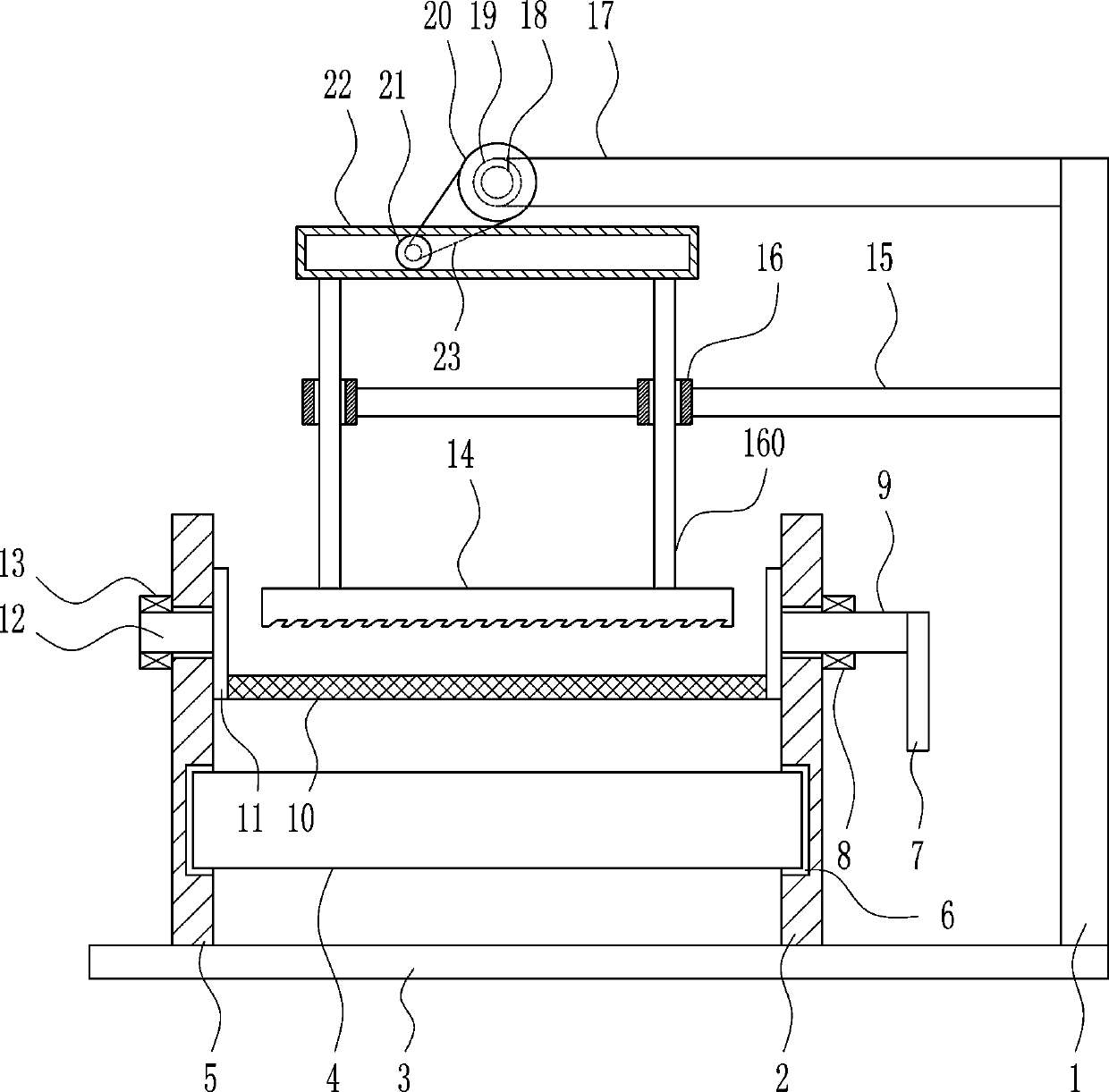

[0024] An agricultural bean beating device, such as Figure 1-6 As shown, it includes a bracket 1, a first support plate 2, a bottom plate 3, a collection tank 4, a second support plate 5, a crank handle 7, a first bearing seat 8, a first rotating shaft 9, a screen plate 10, a processing frame 11, The second rotating shaft 12, the second bearing seat 13, the pressing plate 14, the third support plate 15, the guide sleeve 16, the lifting rod 160, the mounting plate 17, the third rotating shaft 18, the motor 19, the disk 20, the first slider 21 , the lifting frame 22 and the connecting plate 23, the top of the bottom plate 3 is provided with the second support plate 5, the first support plate 2 and the support 1 in sequence from left to right, and the second support plate 5 and the first support plate 2 are symmetrically opened inside. Groove 6 is arranged, and collection groove 4 is placed in groove 6, and the left wall upper part of the second support plate 5 and the first sup...

Embodiment 2

[0026] An agricultural bean beating device, such as Figure 1-6 As shown, it includes a bracket 1, a first support plate 2, a bottom plate 3, a collection tank 4, a second support plate 5, a crank handle 7, a first bearing seat 8, a first rotating shaft 9, a screen plate 10, a processing frame 11, The second rotating shaft 12, the second bearing seat 13, the pressing plate 14, the third support plate 15, the guide sleeve 16, the lifting rod 160, the mounting plate 17, the third rotating shaft 18, the motor 19, the disk 20, the first slider 21 , the lifting frame 22 and the connecting plate 23, the top of the bottom plate 3 is provided with the second support plate 5, the first support plate 2 and the support 1 in sequence from left to right, and the second support plate 5 and the first support plate 2 are symmetrically opened inside. Groove 6 is arranged, and collection groove 4 is placed in groove 6, and the left wall upper part of the second support plate 5 and the first suppo...

Embodiment 3

[0029] An agricultural bean beating device, such as Figure 1-6 As shown, it includes a bracket 1, a first support plate 2, a bottom plate 3, a collection tank 4, a second support plate 5, a crank handle 7, a first bearing seat 8, a first rotating shaft 9, a screen plate 10, a processing frame 11, The second rotating shaft 12, the second bearing seat 13, the pressing plate 14, the third support plate 15, the guide sleeve 16, the lifting rod 160, the mounting plate 17, the third rotating shaft 18, the motor 19, the disk 20, the first slider 21 , the lifting frame 22 and the connecting plate 23, the top of the bottom plate 3 is provided with the second support plate 5, the first support plate 2 and the support 1 in sequence from left to right, and the second support plate 5 and the first support plate 2 are symmetrically opened inside. Groove 6 is arranged, and collection groove 4 is placed in groove 6, and the left wall upper part of the second support plate 5 and the first sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com