Anti-detaching clamping-type ball valve

A compression-type, anti-extrusion technology, which is applied to valve details, valve devices, valve housing structures, etc., can solve problems such as copper tube prolapse, achieve the effect of improving the clamping strength and eliminating hidden dangers of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

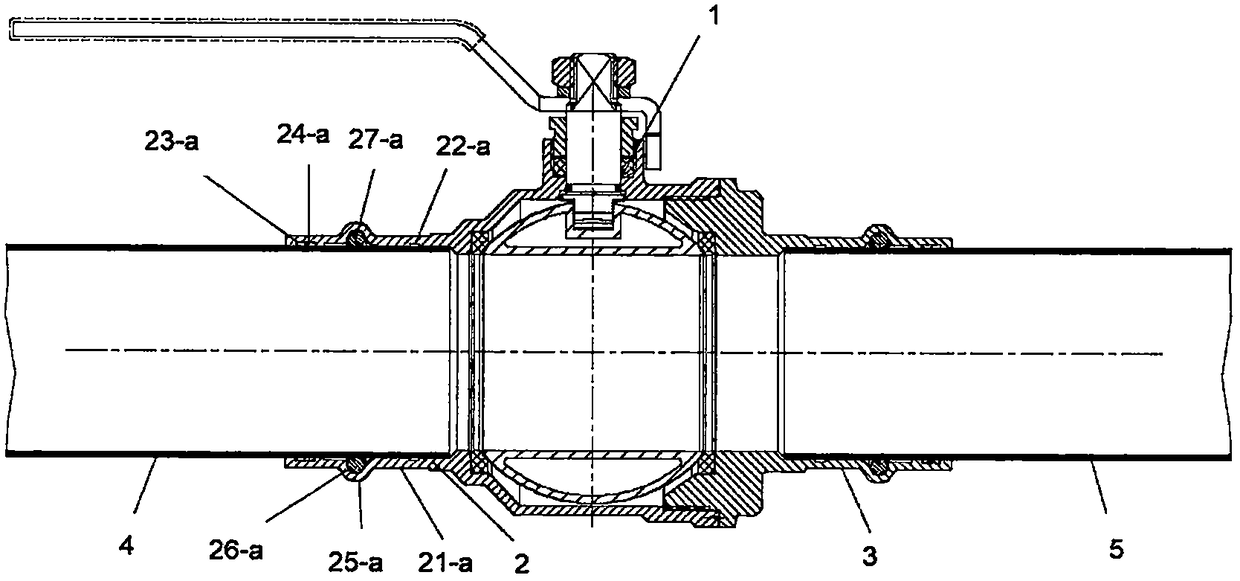

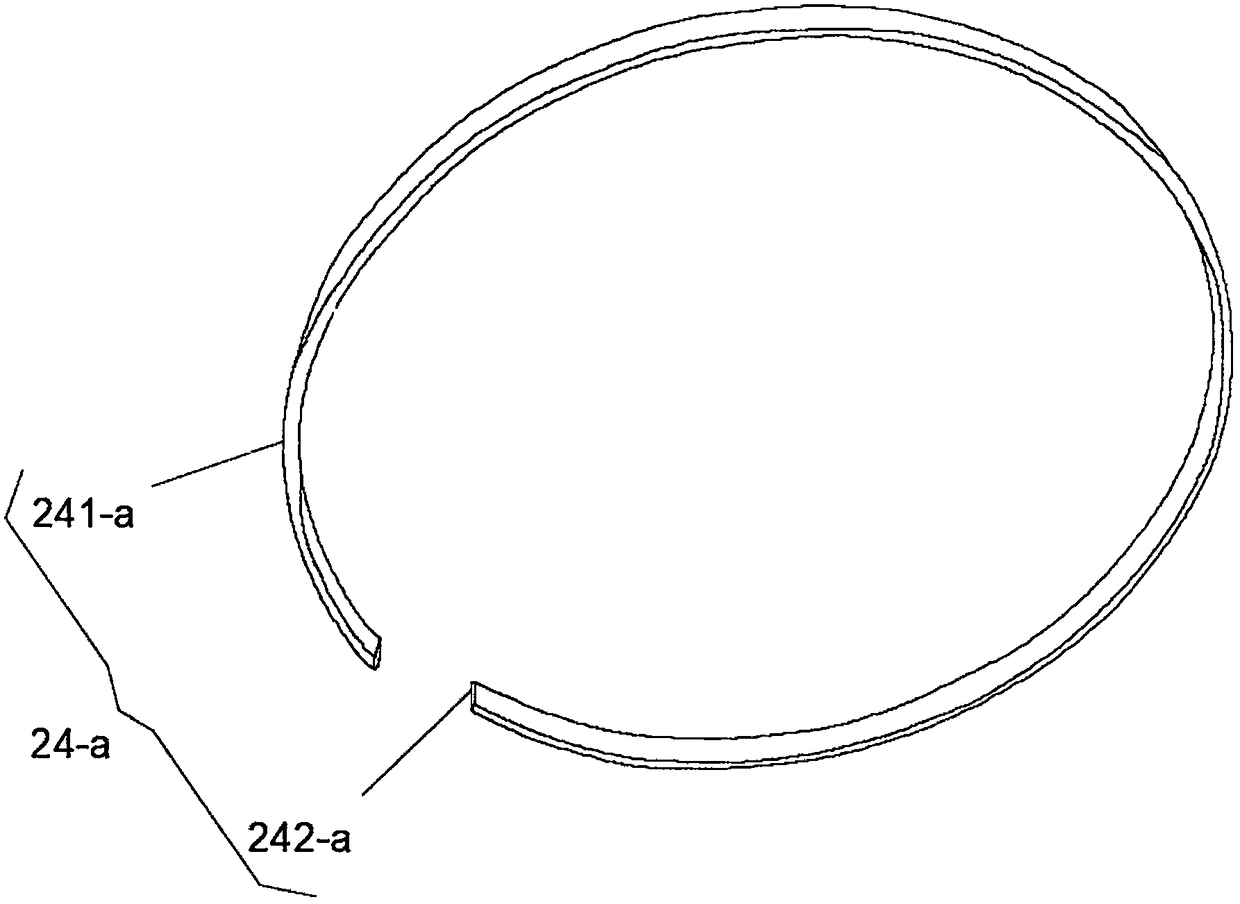

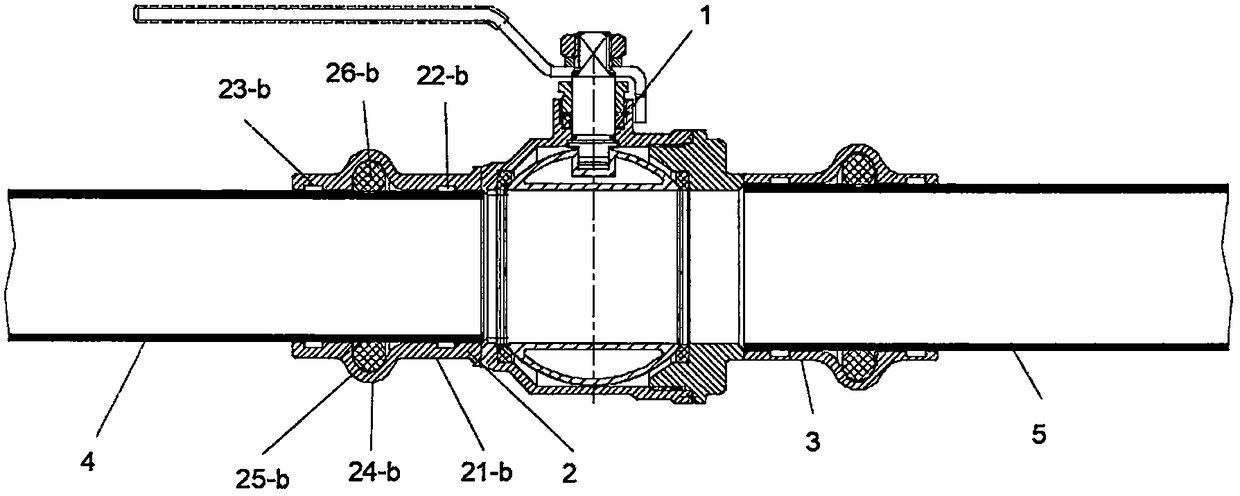

[0018] see figure 1 and figure 2 , the present invention proposes the first embodiment:

[0019] A compression-type ball valve with anti-protrusion, comprising a ball valve body 1, the input end of the ball valve body 1 is fixedly equipped with a left side compression part 2 communicating with the ball valve body 1, and the output end of the ball valve body 1 is fixedly equipped with a ball valve body 1 The connected right crimping part 3, the left copper tube 4 is inserted into the inside of the left crimping part 2, and the right copper tube 5 is plugged into the inside of the right crimping part 3.

[0020] The copper tube 4 on the left side and the copper tube 5 on the right side have the same size and are made of copper material. In actual use, use a collet tool to evenly squeeze the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com