Ball valve capable of prolonging service lifetime

A ball valve and life-span technology, applied in the direction of using liquid cleaning methods, valve devices, cleaning methods and appliances, etc., can solve the problem of adhesions on the inner wall of the ball valve cavity, blockage of the ball valve, and adhesions on the inner wall of the ball valve cavity, etc. Problems, easy to use, prolong service life, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

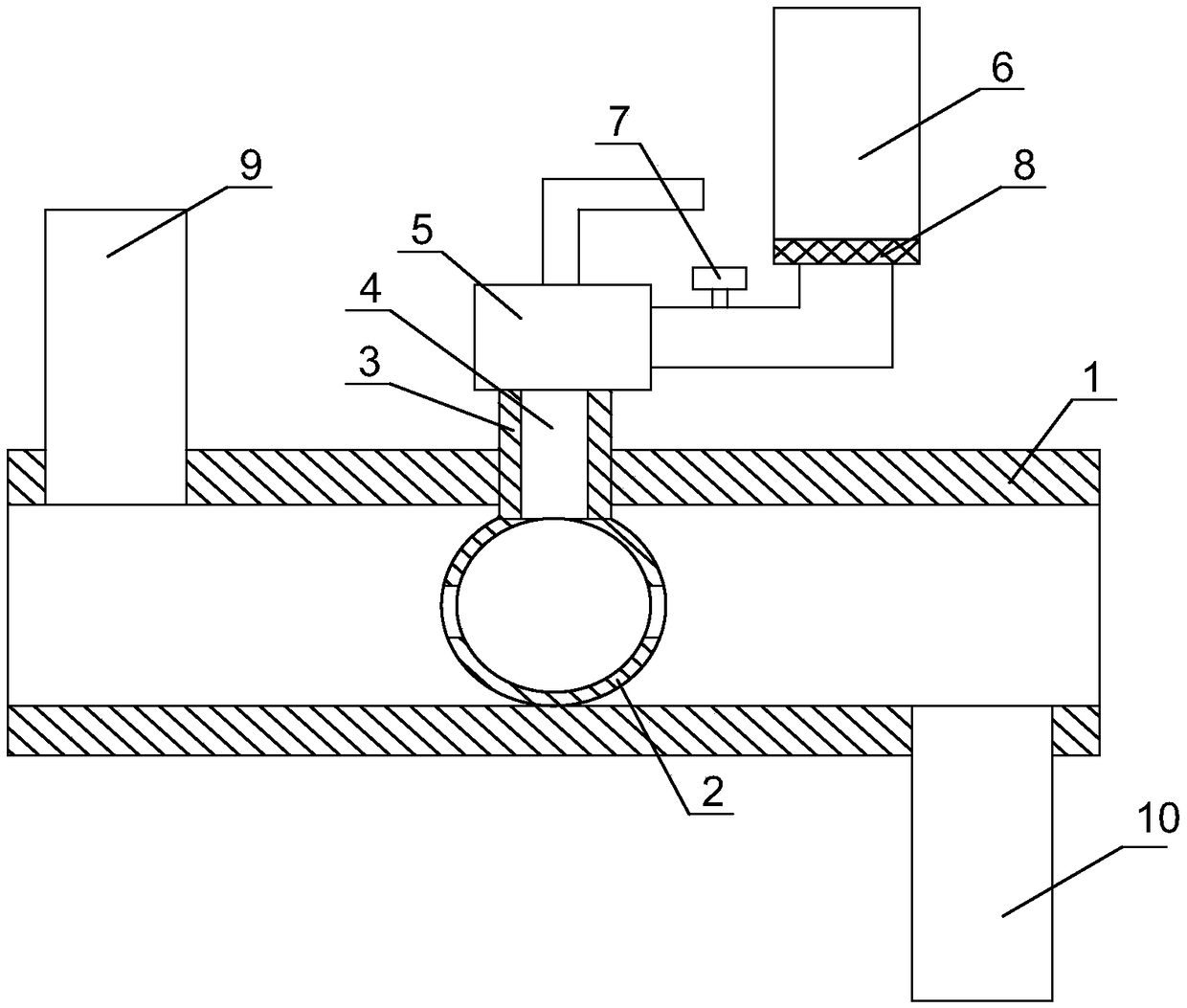

[0023] Such as figure 1 As shown, the ball valve with extended service life of the present invention includes a valve body 1, a valve core 2, and a valve stem 3. The valve core 2 is located inside the valve body 1, and the valve stem 3 is vertically connected above the valve body 1 and connected to the valve body. The core 2 is fixedly connected, the interior of the valve core 2 is provided with a cavity for fluid to flow through, and the interior of the valve stem 3 is provided with a channel 4 communicating with the internal cavity of the valve core 2, and the channel 4 is along the axial direction of the valve stem 3 Through the valve stem 3, the top of the valve stem 3 is installed with a control valve 5 communicating with the channel 4, the outlet of the control valve 5 is communicated with the channel 4, and the inlet of the control valve 5 is communicated with a container 6 with cleaning agent inside. 6 is located on the side of the control valve 5 and above the inlet p...

Embodiment 2

[0026] Based on Embodiment 1, a flow meter 7 is installed at the inlet end of the control valve 5 . The flowmeter can reasonably measure the cleaning agent that passes into the valve core, which can not only ensure that a sufficient amount of cleaning agent enters the valve core, but also avoid the waste of cleaning agent.

Embodiment 3

[0028] Based on the above embodiments, the side wall of the valve body 1 close to its inlet end communicates with a first branch pipe 9 , and the side wall of the valve body 1 near its outlet end communicates with a second branch pipe 10 .

[0029] The cooperation between the first branch pipe and the second branch pipe can discharge the cleaning agent inside the valve core, and can also pass clean water into the valve core to clean the valve core. The first branch pipe and the second branch pipe provide another flow path for the ball valve .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com