A yarn dyeing process

A yarn and process technology, applied in the field of yarn dyeing process, can solve the problems of long time required, time cost, high labor cost, high site cost, and many equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

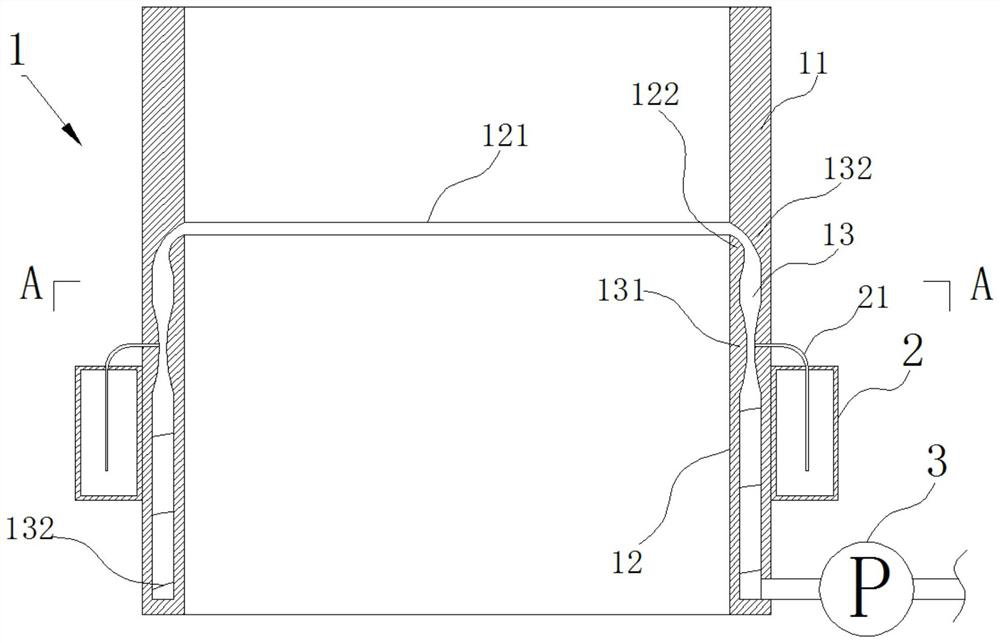

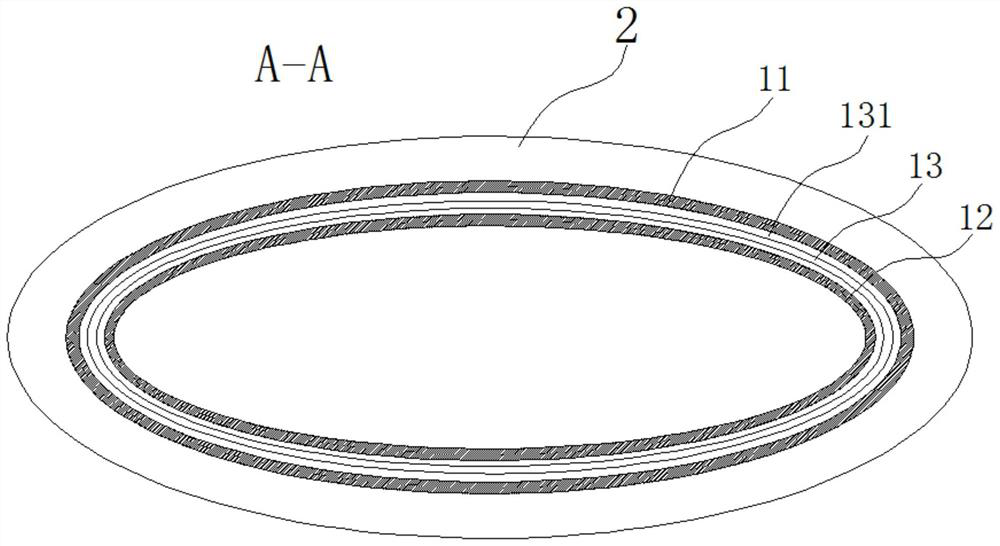

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

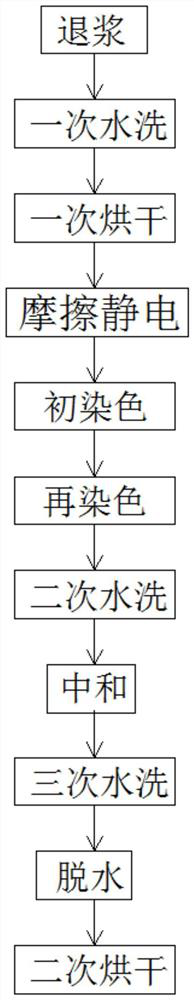

[0055] Such as figure 1 Shown, a kind of yarn dyeing process comprises the following steps carried out in sequence:

[0056]① Desizing, the formed yarn is unwound through the unwinding mechanism and transported to the desizing tank for soaking. The liquid temperature in the desizing tank is kept at 80°-90°, and the soaking time is kept at 20-60 minutes; The yarn is subjected to ultrasonic vibration to remove the pulp on the yarn;

[0057] ②Water washing once to clean the desized yarn;

[0058] ③ One-time drying, drying the yarn that has been washed once;

[0059] ④Frictional static electricity, choose a suitable material to contact and friction with the yarn to make the yarn carry charges;

[0060] ⑤Initial dyeing, the dye is atomized and sprayed to the surface of the yarn through the atomization device to dye, the temperature of the dye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com