Wool washing device

A technology for scouring wool and wool, which is applied in the direction of animal loose hair fiber washing/scouring, etc., can solve the problems of short washing time, high oil content in scouring wool, affecting the quality of scouring wool, etc., and achieves simple structure, high reliability, and disassembly. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

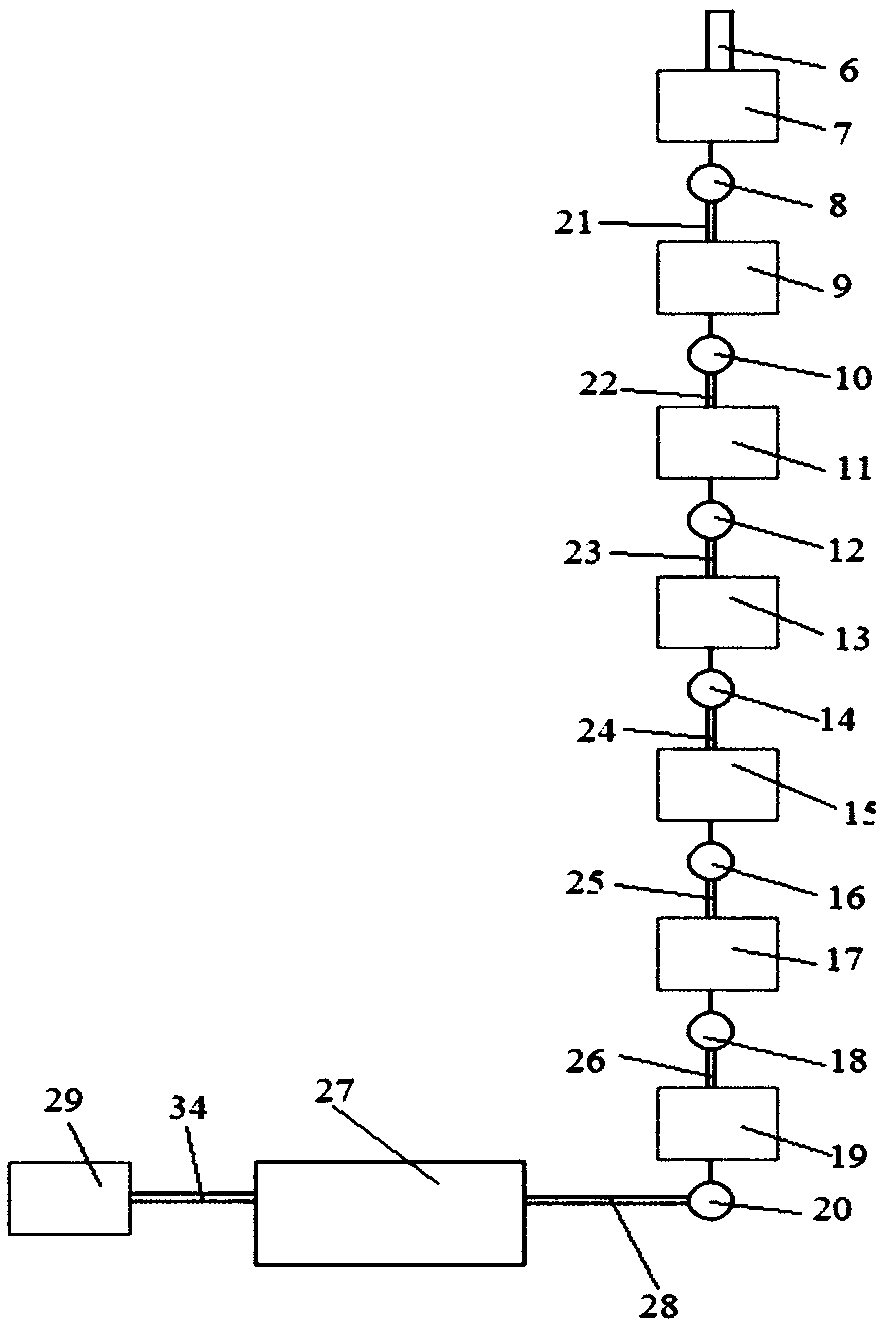

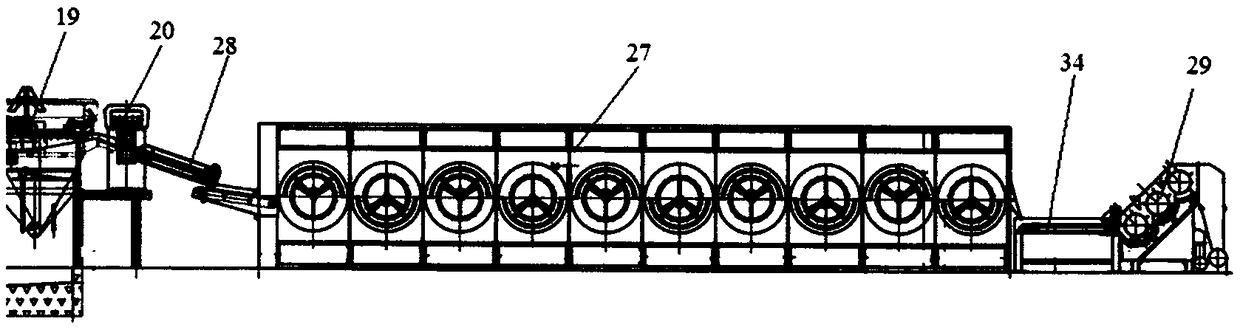

[0018] like figure 1 , 2 Shown: a wool scouring device, including a weighing conveyor 6, a first scouring tank 7, a first padding car 8, a second scouring tank 9, a second padding car 10, a third scouring tank 11, a The third rolling car 12, the fourth scouring tank 13, the fourth rolling car 14, the fifth scouring tank 15, the fifth rolling car 16, the sixth scouring tank 17, the sixth rolling car 18, the seventh scouring tank 19 , the seventh rolling car 20, the first flat curtain 21, the second flat curtain 22, the third flat curtain 23, the fourth flat curtain 24, the fifth flat curtain 25, the sixth flat curtain 26, the oven 27, the seventh flat curtain 28. Sanxilin loosening and cleaning machine 29, rake teeth 30, temperature measuring device 31, mud drop bucket 32, mud discharge port 33, eighth flat curtain 34, etc.

[0019] A scouring device, comprising a scouring section and a drying section, the scouring section includes a first scouring tank 7, a first padding car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com