Overflow-free concrete stirrer material falling device

A concrete mixer and overflow technology, which is applied in the direction of selling raw material supply devices, can solve problems such as blockage of the feeding port, and achieve the effects of improving the feeding speed, reasonable structure design, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

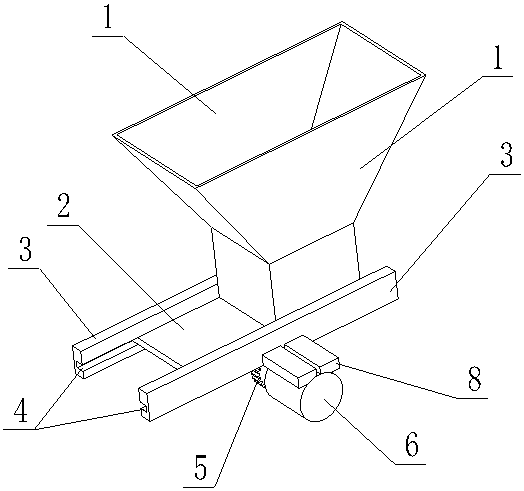

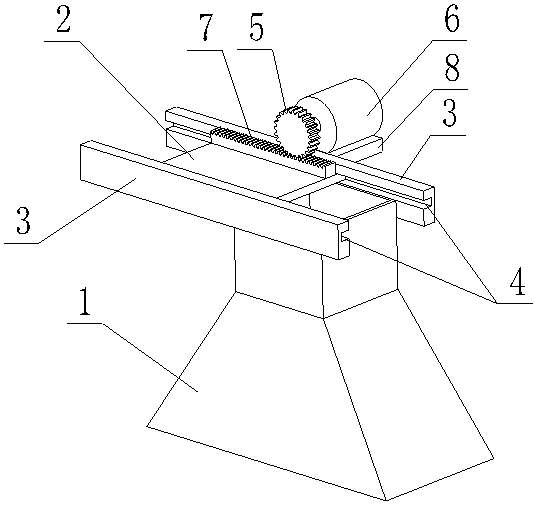

[0011] Specific embodiment one, please refer to figure 1 and figure 2 , a discharge device for a spill-free concrete mixer, including a discharge hopper 1, a baffle plate 2, a guide rail 3 and a servo motor 6, the guide rail 3 is fixed on the bottom of the discharge hopper 1, and the inner surface of the guide rail 3 is correspondingly provided with a stop Plate guide groove 4, said baffle plate guide groove 4 is provided with a baffle plate 2, said baffle plate 2 is fixed with a rack 7, said servo motor 6 is fixed on the guide rail 3 by a servo motor fixing plate 8, said The servo motor 6 is provided with a gear 5 , the gear 5 and the rack ) are in mesh with each other, and the servo motor 6 can drive the baffle 2 to slide in the baffle guide groove 4 through the gear 5 and the rack 7 .

[0012] The invention designs a blanking device for a spill-free concrete mixer. The pneumatic valve control of the blanking device for a spill-free concrete mixer is changed to servo motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com