Mould-proof corrosion-prevention treatment process for wicker products

An anti-corrosion treatment and anti-mildew technology, applied in anti-corrosion coatings, manufacturing tools, wood treatment, etc., can solve the problems of easy corrosion, incapable of mass production, short service life, etc., to increase the performance of wear resistance and scratch resistance, anti-mildew and anti-corrosion Excellent effect, prolonging the effective period of anti-mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

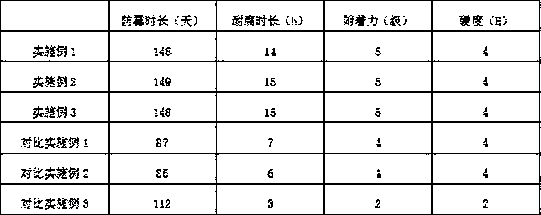

Examples

Embodiment 1

[0022] A mildew-proof and anti-corrosion treatment process for wickerwork, comprising the following steps:

[0023] (1) In June, select willow branches with moderate thickness and no pests and diseases, cut off the top horizontally, then cut off the stems and leaves, and then cut the base of willow branches obliquely to make them oblique; classify willow branches by length , every 5 bundles into a bundle, inserted into the pre-prepared matrix, poured the treatment solution once a day, kept the humidity at 30%, cultivated for 3 days and took it out;

[0024] (2) peeling, softening and weaving the willow branches obtained in step (1) to obtain semi-finished products;

[0025] (3) Immerse the semi-finished product obtained in step (2) into the anti-mold and anti-corrosion treatment agent, supplemented by 40Hz, 1000W ultrasonic operation for 20 minutes, take it out and hang it in an environment of 20°C to drain off the excess anti-mold and anti-corrosion treatment agent, and then ...

Embodiment 2

[0036] A mildew-proof and anti-corrosion treatment process for wickerwork, comprising the following steps:

[0037] (1) In July, select willow branches with moderate thickness and no pests and diseases, cut off the top horizontally, then cut off the stems and leaves, and then cut the base of willow branches obliquely to make them oblique; classify willow branches by length , every 7 roots were bundled into a bundle, inserted into the pre-prepared substrate, poured the treatment solution twice a day, kept the humidity at 40%, and took it out after 4 days of cultivation;

[0038] (2) peeling, softening and weaving the willow branches obtained in step (1) to obtain semi-finished products;

[0039](3) Immerse the semi-finished product obtained in step (2) into the anti-mold anti-corrosion treatment agent, supplemented by 45Hz, 1100W ultrasonic operation for 25 minutes, take it out and hang it in an environment of 25°C to drain off the excess anti-mold anti-corrosion treatment agen...

Embodiment 3

[0050] A mildew-proof and anti-corrosion treatment process for wickerwork, comprising the following steps:

[0051] (1) In August, select willow branches with moderate thickness and no pests and diseases, cut off the top horizontally, then cut off the stems and leaves, and then cut the base of the willow branches obliquely to make them oblique; classify the willow branches by length , every 10 bundles into a bundle, inserted into the pre-prepared matrix, poured the treatment solution twice a day, kept the humidity at 50%, cultured for 5 days and took it out;

[0052] (2) peeling, softening and weaving the willow branches obtained in step (1) to obtain semi-finished products;

[0053] (3) Immerse the semi-finished product obtained in step (2) into the anti-mildew and anti-corrosion treatment agent, supplemented by 50Hz, 1200W ultrasonic operation for 30 minutes, take it out and hang it in an environment of 30°C to drain off the excess anti-mold and anti-corrosion treatment agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com