Marking device and method used for steel tube elbow

A scribing device and pipe bending technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of low work efficiency, cumbersome operation, low precision, etc., and achieve high work efficiency, low operating skill requirements, and high blanking precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. All equivalent changes and modifications made according to the contents of this specification shall fall within the scope of protection claimed by the application of the present invention.

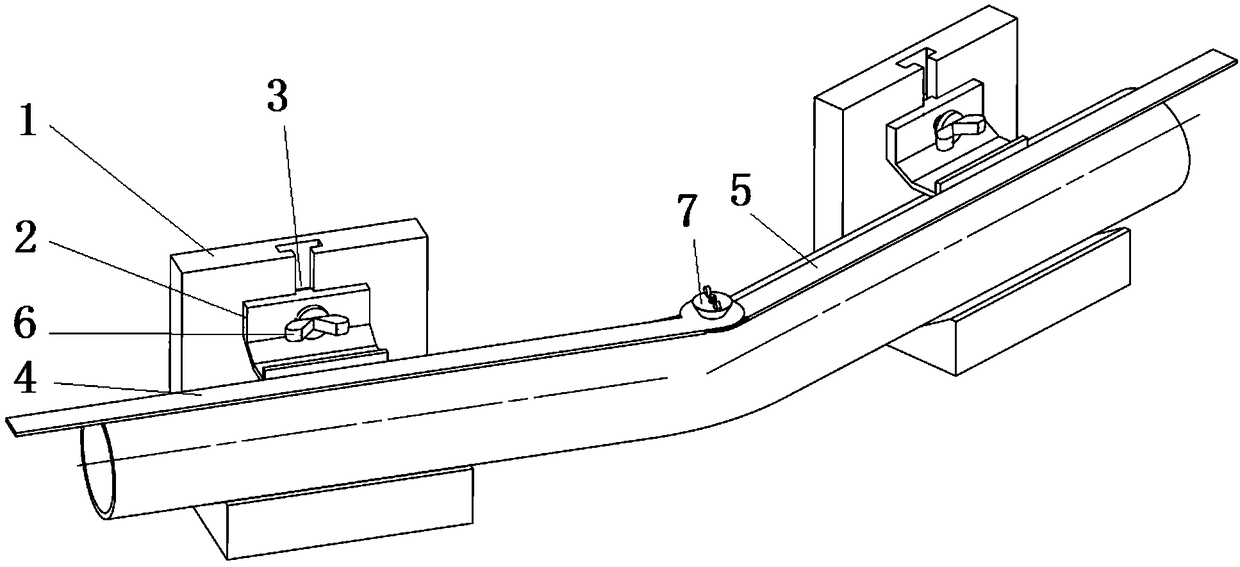

[0039] see figure 1 , figure 1 It shows a line marking device for steel pipe bends, which is used for marking and blanking operations of marine low-speed diesel engine bends. It can be used for pipes with a diameter of steel pipe bend; the marking device includes two positioning seat components and a marking ruler.

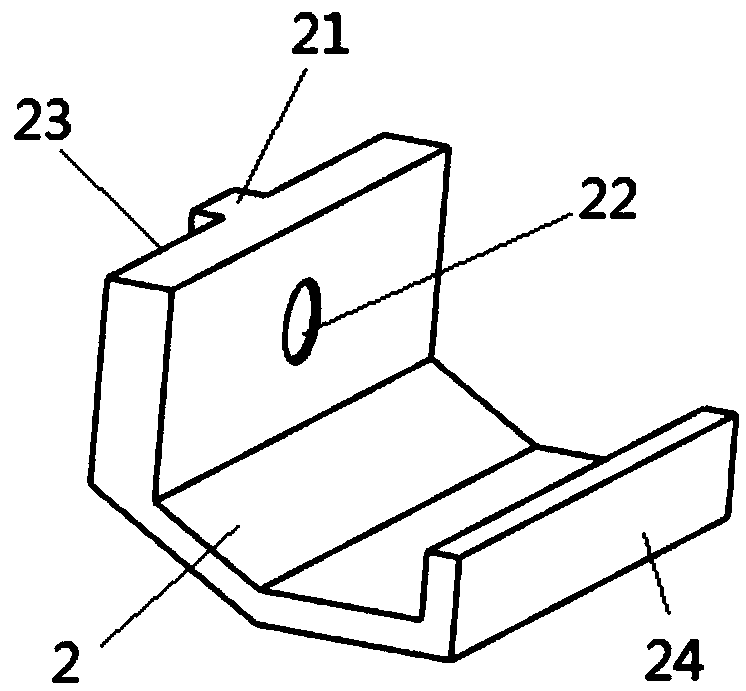

[0040] The positioning seat assembly can move, and includes a base block 1 , a limiting plate 2 , a T-shaped block 3 and fastening bolts 6 .

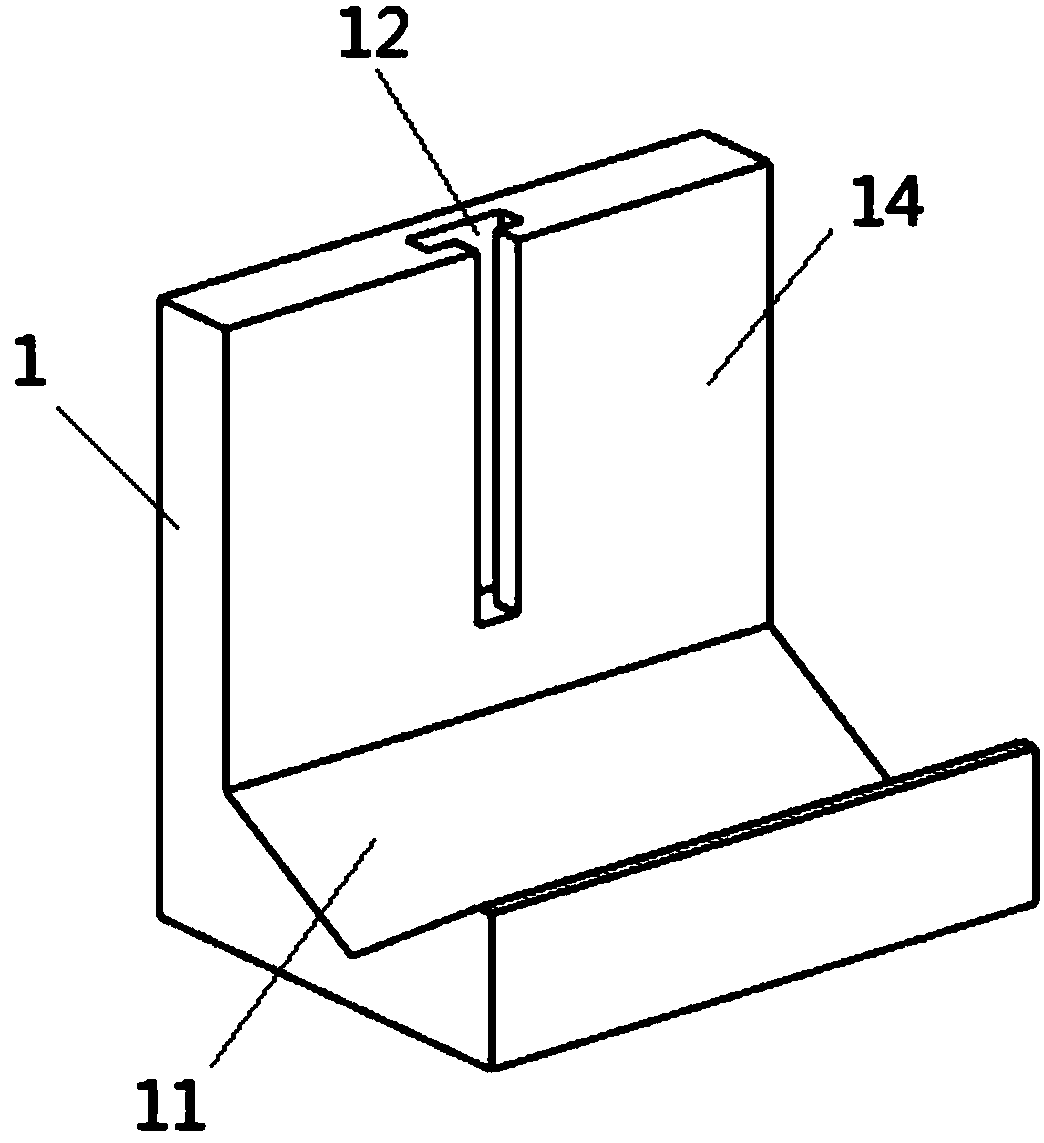

[0041] see figure 2 , the lower part of the base block 1 is provided with a V-shaped groove 11 for placing steel pipes. The opening of the V-shaped groove 11 is upward, and the angle formed by its two surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com