Folding type rubber extruding gun

A folding type, glue gun technology, applied in the field of glue guns, can solve the problems of insufficient versatility, high cost, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

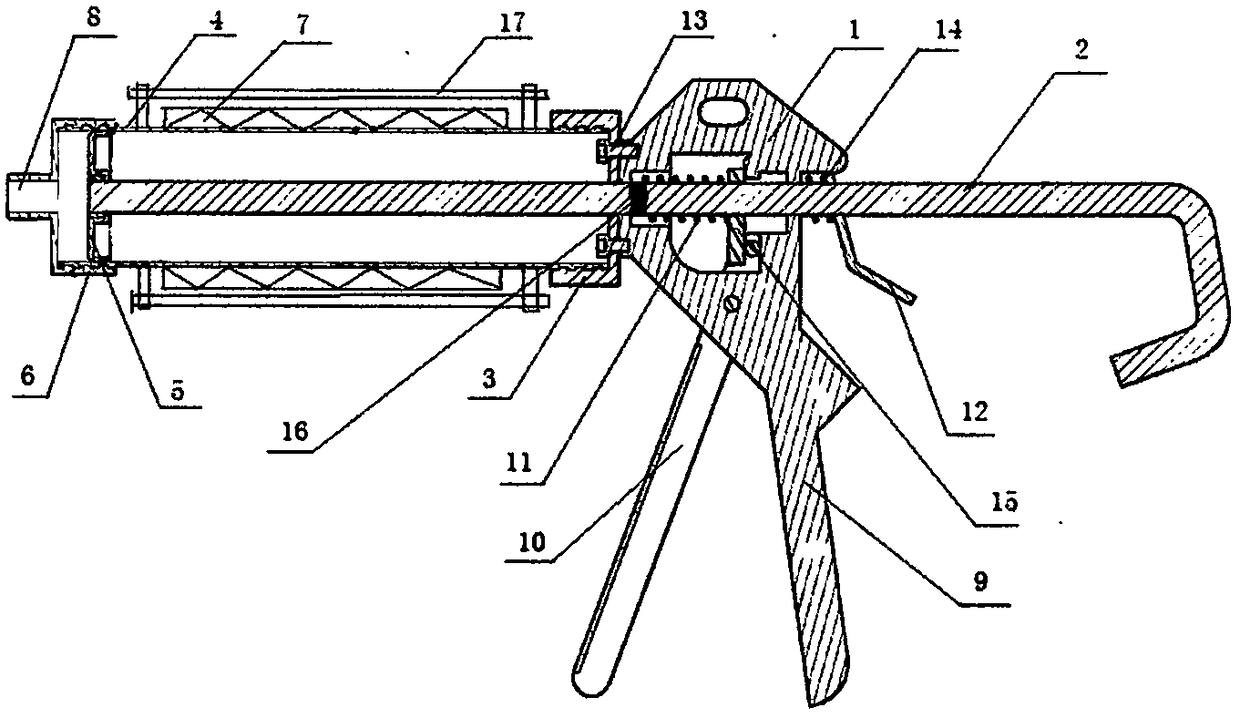

[0029] Such as figure 1 As shown, a folding glue extrusion gun is composed of a gun bracket 1, a push-pull rod 2, a piston 5, a barrel connecting pipe seat 3, a barrel 4, a head 6 and a driving device. Barrel 4 adopts telescopic gun barrel, and described push-pull rod 2 adopts telescopic push-pull rod and has locking function.

[0030] The telescopic gun barrel refers to that the cylinder body 4 is made of a bellows 7 or a flexible hose, and the two ends are connected with pipe joints.

[0031] The pipe joints at both ends of the telescopic gun barrel are used as guide rails to adjust the length of the hard rubber cylinder body through two telescopic pull rods 17 .

[0032] The head and the gun barrel are connected by a detachable structure, including but not limited to thread, buckle, flip-type rotary buckle and buckle combined connection;

[0033] The telescopic push-pull rod and the pull rod 17 of the telescopic barrel have a locking function, and adopt telescopic locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com