A regular shape crushing and cutting device for waste power battery inner core

A power battery and cutting device technology, which is applied in the field of waste power battery recycling and pretreatment equipment, can solve the problems of uneven particle size and shape distribution of materials, and achieve the effect of improving the efficiency of winnowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

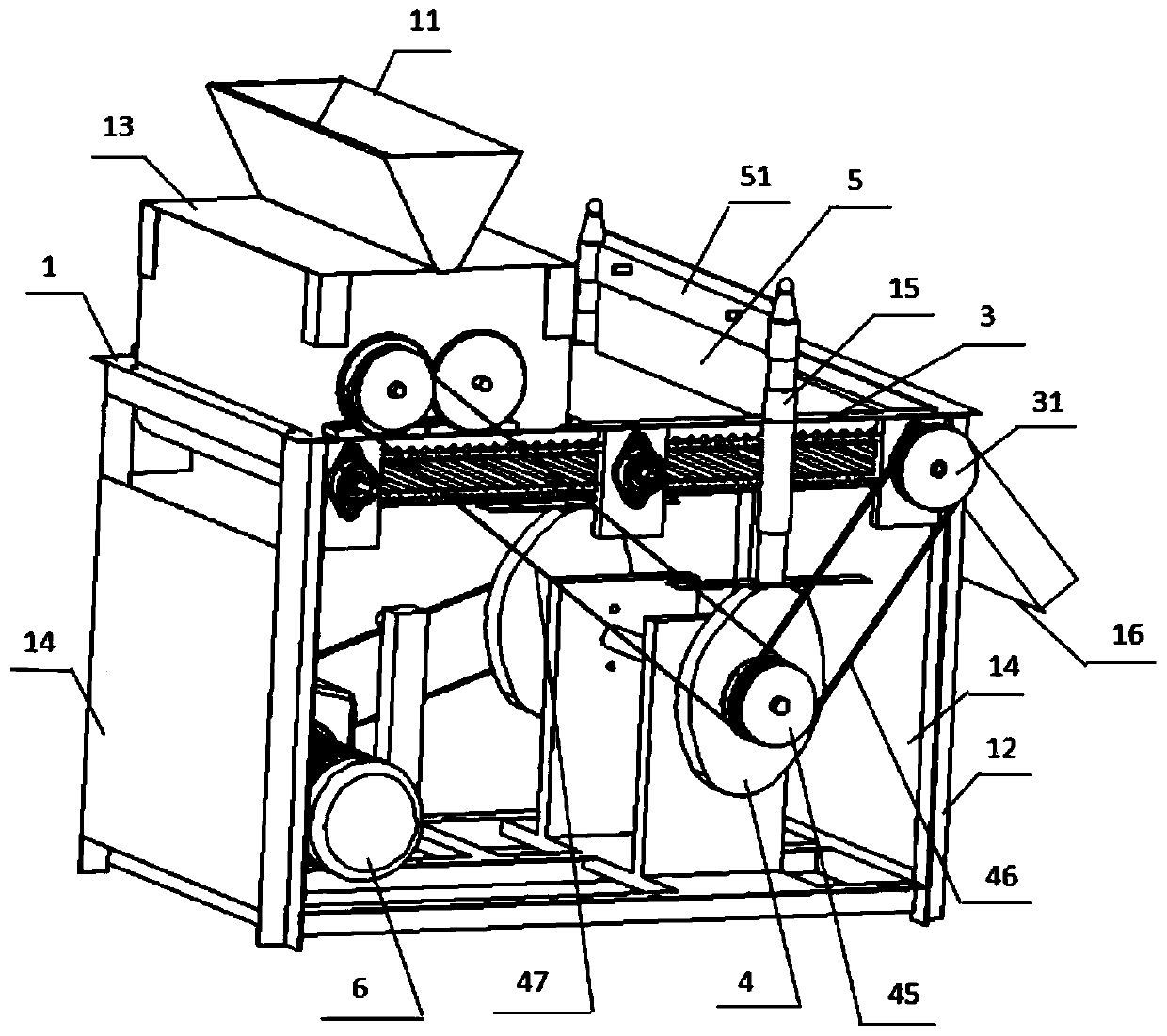

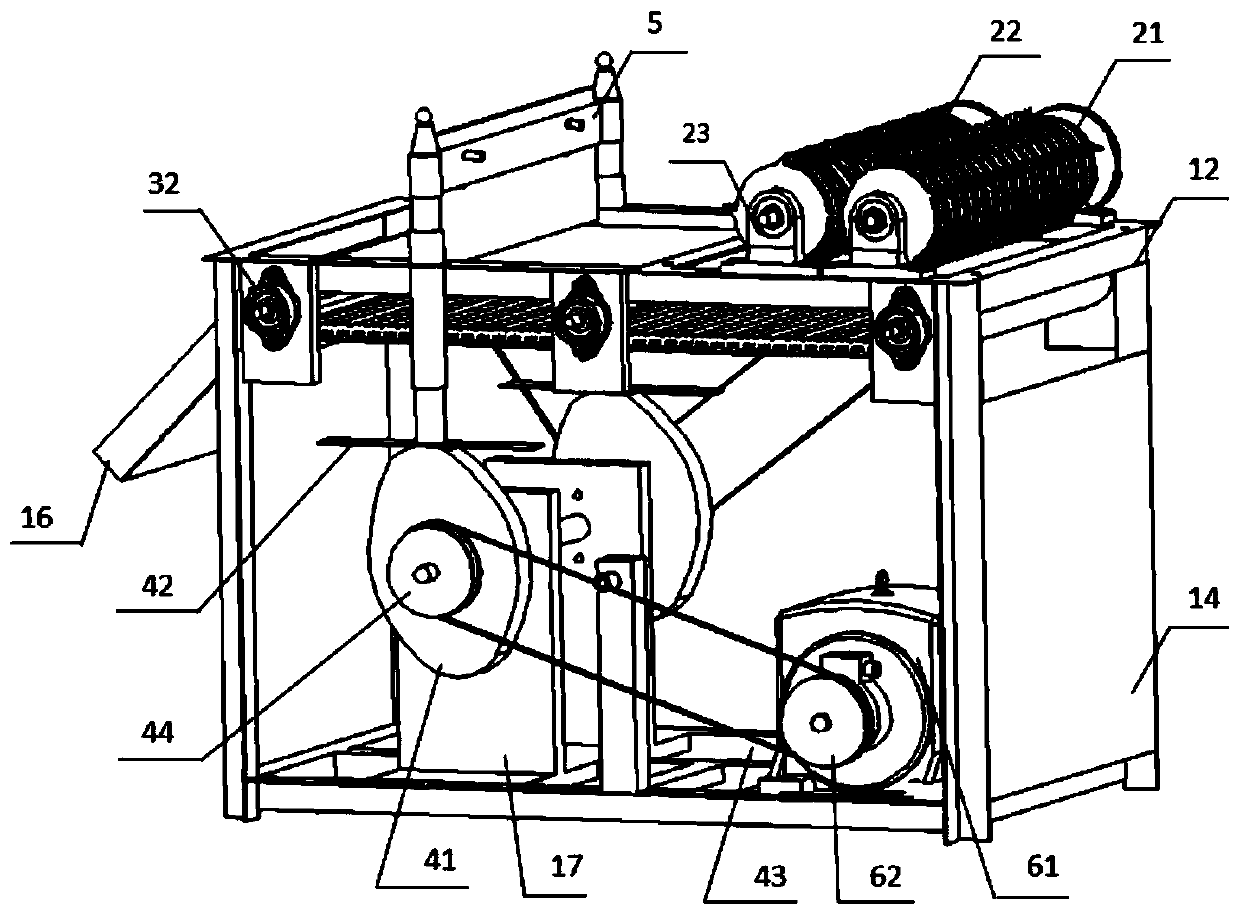

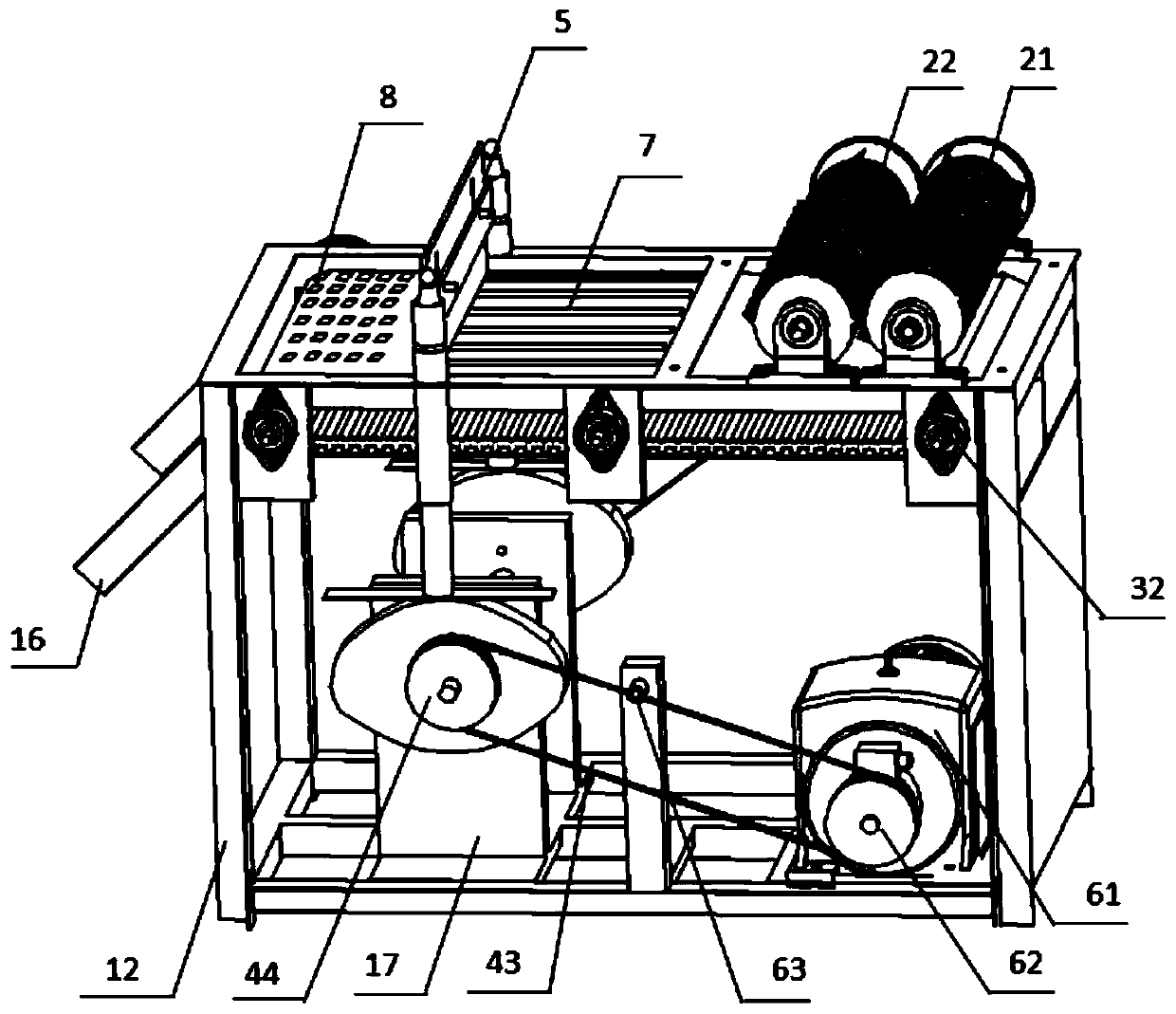

[0035] see Figure 1 to Figure 6 , A regular-shaped crushing and cutting device for the inner core of waste power batteries, including a frame 1, a crushing device 2, a conveyor belt device 3, a push rod mechanism 4, a knife device 5 and a driving device 6. The frame 1 includes a feed hopper 11 and a frame body 12, a crushing device 2 and a cutter device 5 are installed above the frame body 12, a push rod mechanism 4 is installed inside the frame body 12, and the top of the crushing device 2 is connected to the The hopper 11 is connected with the conveyor belt device 3 below the crushing device 2 . The driving device 6 is installed on the lower beam of the frame body 12 , and the driving device 6 includes a motor 61 .

[0036]The crushing device 2 includes a driving hob 21 , a driven hob 22 , four roller bearing housings 23 , a driving pulley 24 and a driven gear 25 . The active hob 21 and the driven hob 22 are arranged in parallel in the horizontal direction, and the journa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com