Printed circuit board production monitoring system and method

A technology for printed circuit boards and monitoring systems, applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve the problems of continuous welding, poor welding ability, and inability to completely remove oxides, and achieves significant effects and uses. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

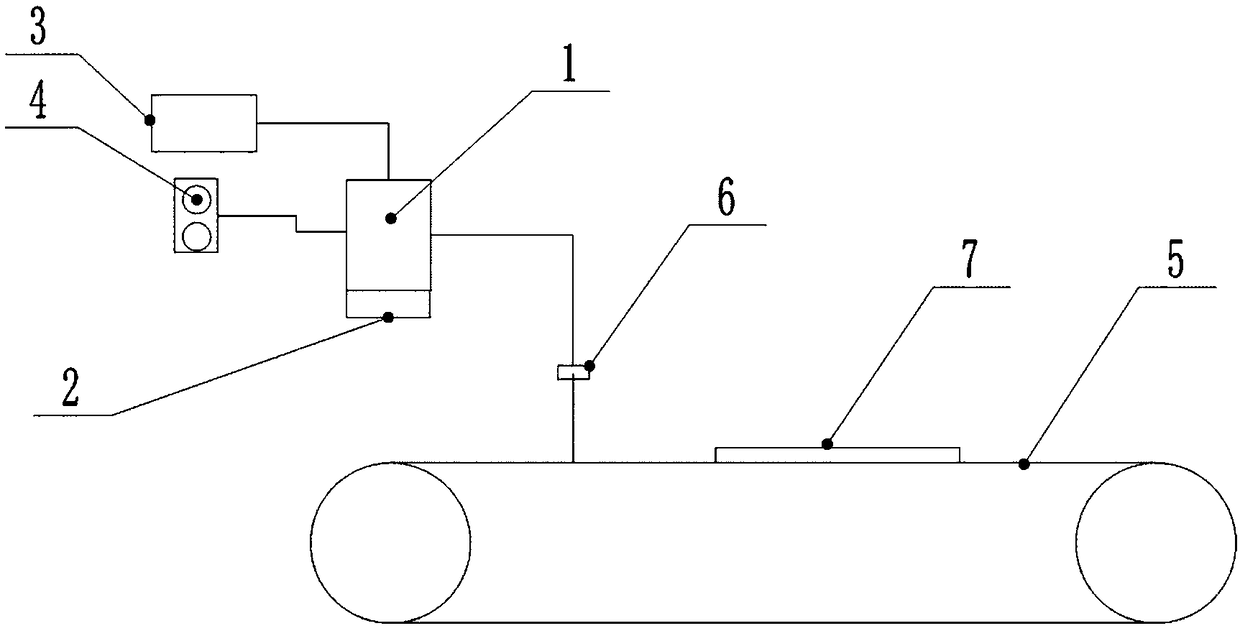

[0018] Such as figure 1 As shown, a printed circuit board production monitoring system includes a circuit board conveying device, a circuit board sensing device is arranged above the conveying device, the sensing device is connected to the processor 1, and the processor 1 is also connected to an alarm device. Described alarm comprises timer 2 and buzzer 3, and timer 2 and buzzer 3 all circuit connections processor 1. Alarm also includes indicator light 4.

[0019] Specifically, the transmission device is a conveyor belt 5, and an infrared distance measuring sensor 6 is arranged above the conveyor belt 5 as a circuit board sensing device. 7 is sent to the reflow soldering to carry out the reflow of surface mount components, and within 30 minutes (the time can be adjusted appropriately) is preset in the processor 1, when the circuit board 7 passes by on the conveyor belt 5, the emission of the infrared distance measuring sensor 6 terminal reflects a signal to the receiving end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com