Testing system and testing method for measuring rock fracture multiple-phase seepage characteristics

A multi-phase seepage and rock fissure technology, which is applied in measurement devices, soil material testing, material inspection products, etc., can solve the problems of the overall microscopic topography, the difficulty of accurately obtaining the tortuosity, the large measurement error, and the extreme influence on the measurement accuracy. Large and other problems, to achieve the effect of facilitating promotion and application, ensuring experimental accuracy, and accurate opening distribution

Active Publication Date: 2018-10-26

CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF9 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] First of all, in terms of measuring the multiphase saturation of rock fractures, the existing technology mostly uses rock fractures for experiments, and the change characteristics of the fluid phase structure inside the fractures cannot be observed, and it is difficult to measure the local saturation of the fractures; secondly, in the capillary pressure In terms of measurement, the existing technology mostly drills holes in rock fissures, and inserts the tensiometer into the rock fissure for measurement. On the one hand, it damages the part of the fissure, and on the other hand, the position of the tensiometer has a great influence on the accuracy of measuremen

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

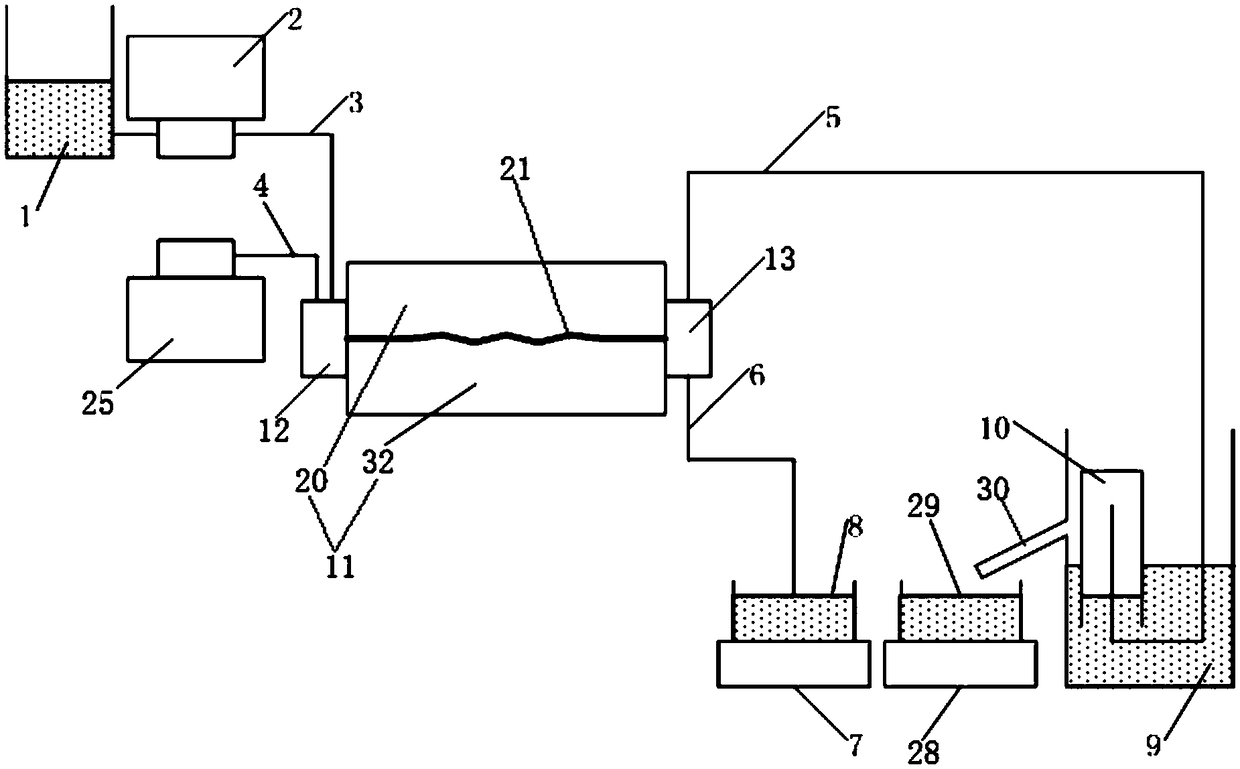

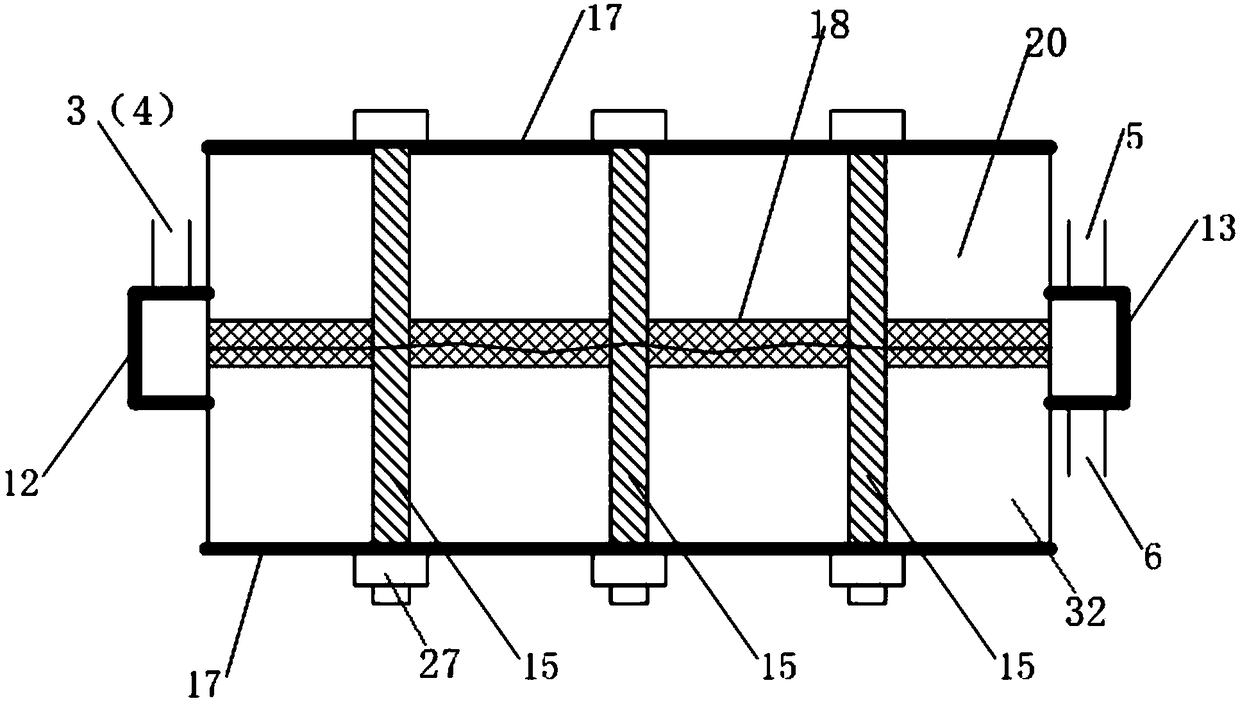

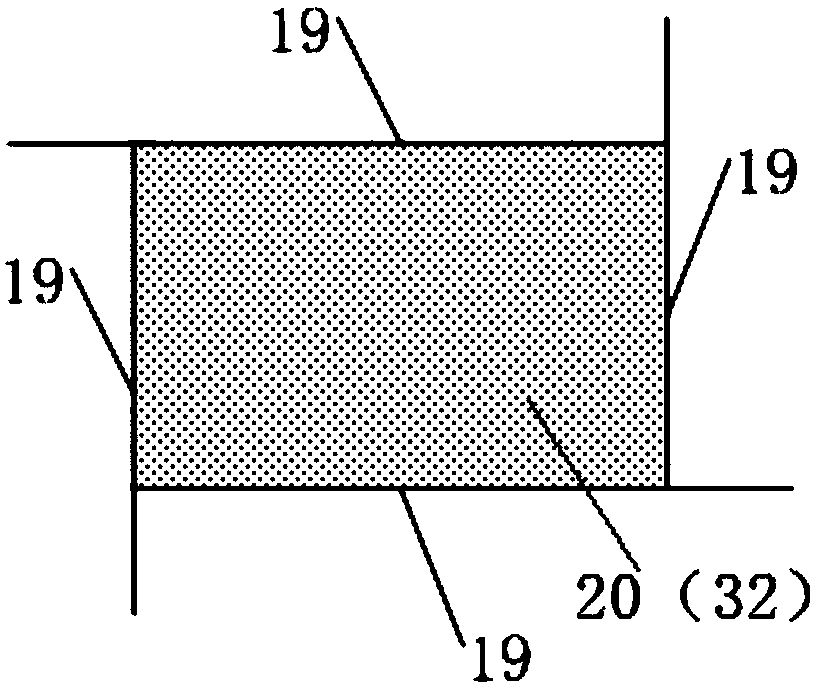

The invention provides a testing system for measuring rock fracture multiple-phase seepage characteristics. The testing system comprises a water supply device, a gas supply device, a multiple-phase seepage work chamber, a water collection device and a gas collection device, wherein the multiple-phase seepage work chamber comprises clamping plates compressed at the two sides of a fracture sample, an inlet end cap and an outlet end cap which are arranged on a fracture on the opposite surfaces of the fracture sample respectively, the water supply device and the gas supply device are both connected with the inlet end cap, and the water collection device and the gas collection device are both connected with the outlet end cap. Compared with other molding methods (such as miniature engraving machining), the testing system has the advantages that the structure is simple, the testing system is economical and practical, and still can complete the experimental process better under less investment, the practicability is high, and the popularization and application are convenient.

Description

technical field [0001] The invention relates to many engineering and earth science technical fields of engineering geology and hydrogeology, in particular to a test system and a test method for measuring multiphase seepage characteristics of rock fissures. Background technique [0002] Multiphase flow in rock fissures is very common, for example, it is involved in the study of rock slope landslides induced by heavy rain, nuclear waste migration, underground energy and mineral mining, and environmental engineering, and it plays an important role in the economic benefits and safety of projects. critical use. The determination of the multiphase seepage characteristics of rock fractures is the premise of analyzing the law of multiphase seepage movement in rock mass, and the multiphase seepage characteristics of rock fractures have always been a hot topic in the field of geology and technology. [0003] The multiphase seepage characteristics of rock fractures include the saturat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N15/08G01N33/24

CPCG01N15/08G01N33/24

Inventor 李毅罗舸旋子李博安毕丽罗伟蒋煌斌李想

Owner CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com