A built-in preload adjustable single-sided film throttling static pressure lead screw pair

A built-in, screw pair technology, which is applied in the direction of transmission, transmission parts, gear lubrication/cooling, etc., can solve the problems of poor sensitivity of slide valves, eliminate vibration, realize active compensation of pressure feedback, and smooth deformation changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

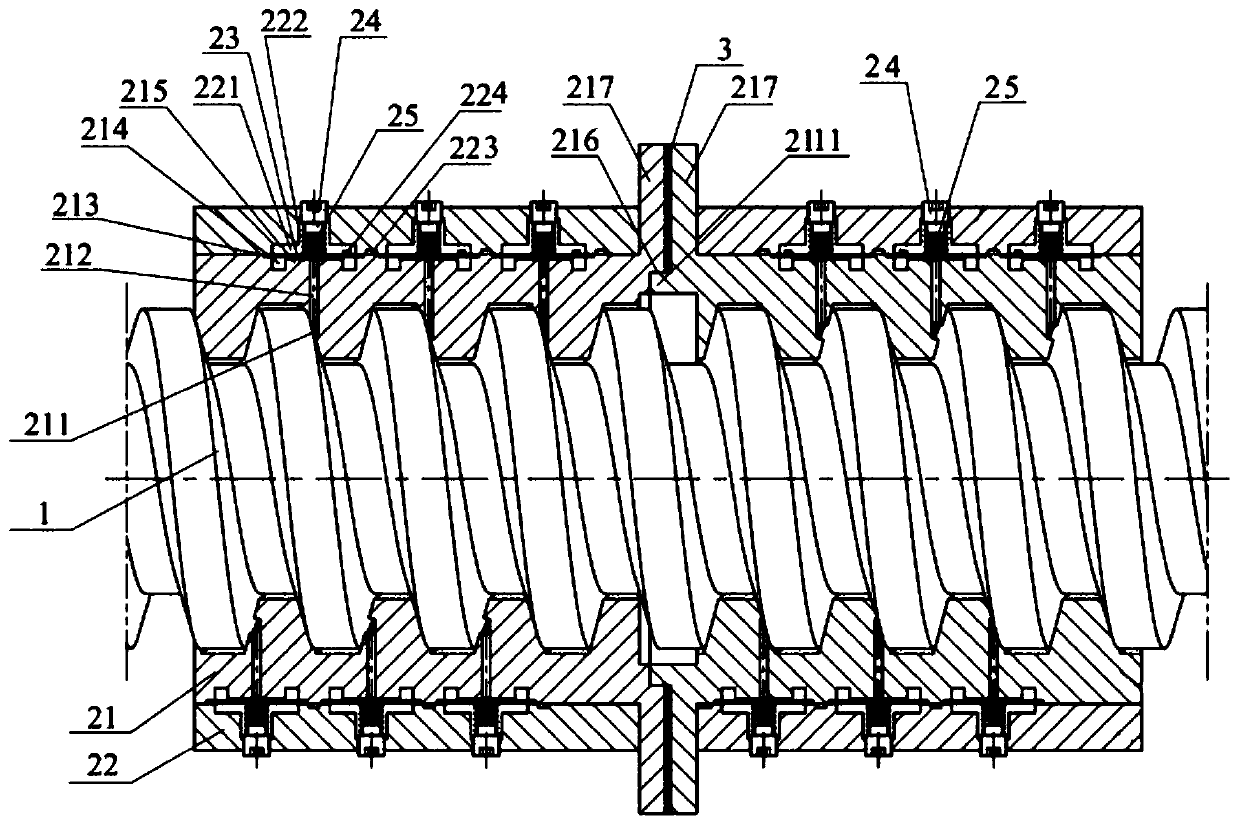

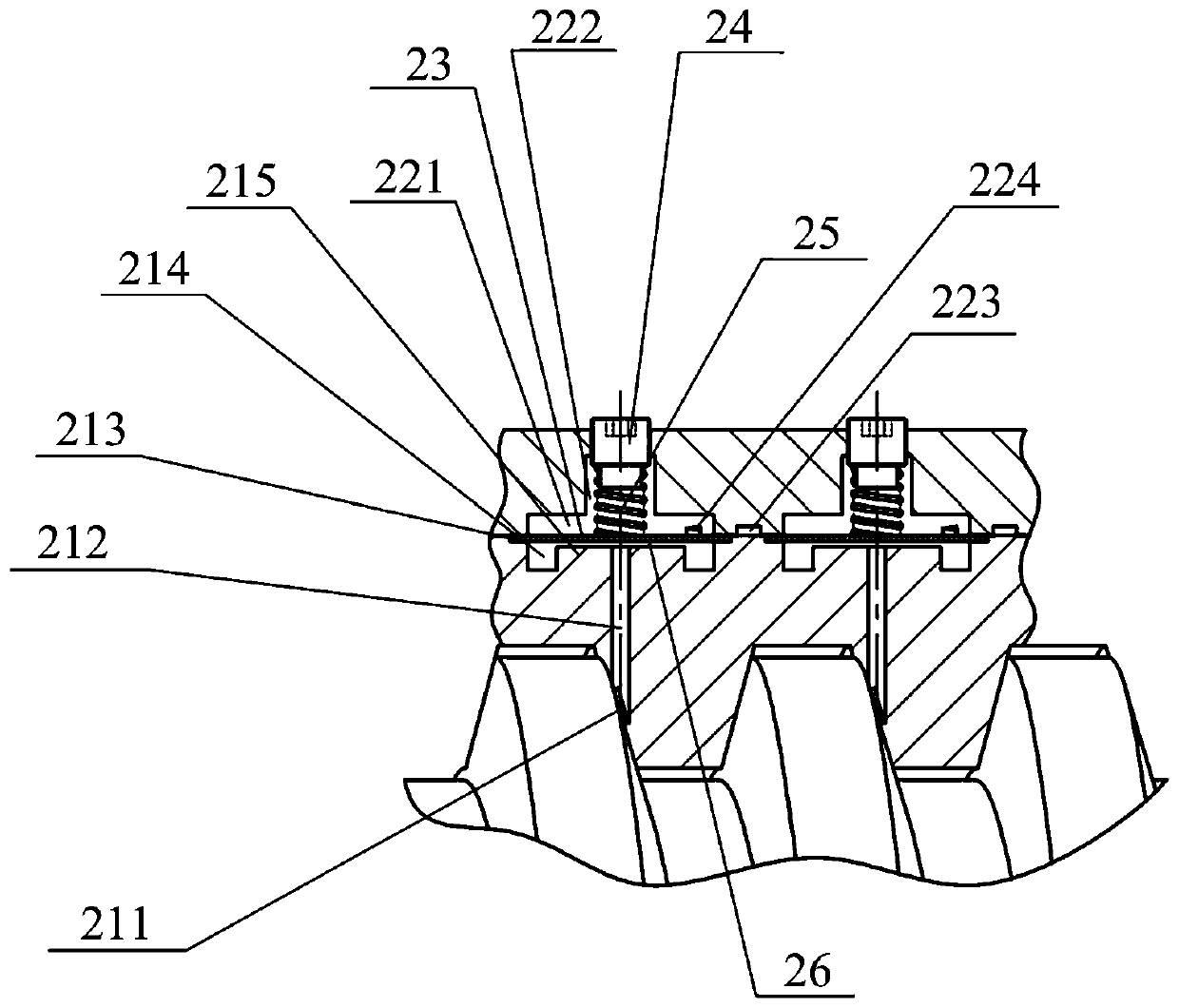

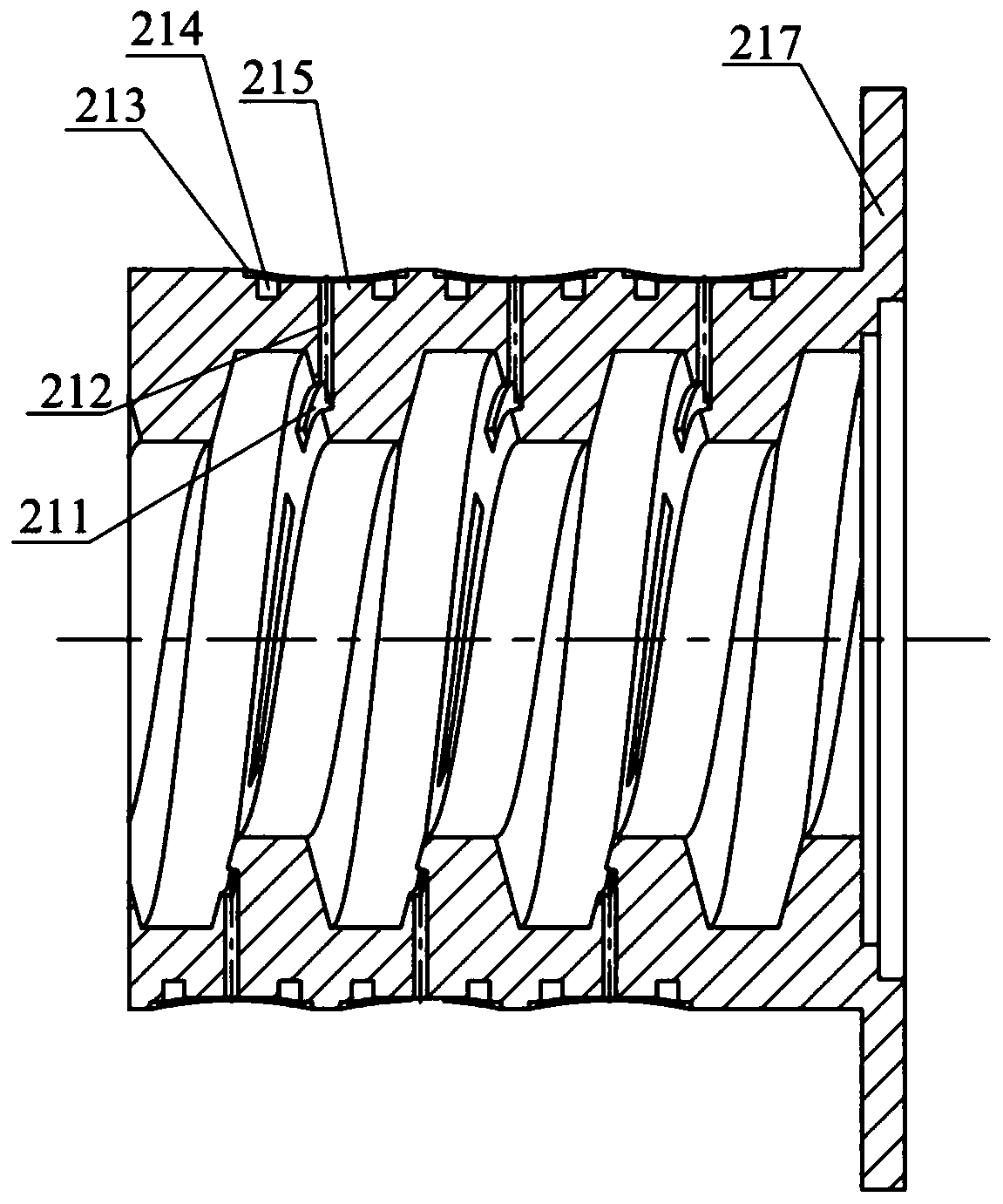

[0031] A built-in preload adjustable single-sided film throttling static pressure lead screw pair, such as Figure 1 to Figure 7 As shown, it includes a lead screw 1, and also includes a nut that cooperates with the lead screw 1. The nut includes an inner sleeve 21, an outer sleeve 22, a film 23, an adjustment device 24 and a spring 25, wherein the inner sleeve 21 and the outer sleeve 22 are installed in cooperation with each other, the adjustment device 24 and the spring 25 are arranged on the outer sleeve 22, and the film 23 is fixed by the inner sleeve 21 and the outer sleeve 22. The following will focus on describing the inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com