Movable coating forming device and forming method

A molding equipment and molding method technology, applied in the direction of spray device, spray booth, etc., can solve the problems of low automation use efficiency, inability to spray comprehensively, inconvenient movement and placement, etc., and achieve the effect of reasonable principle, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

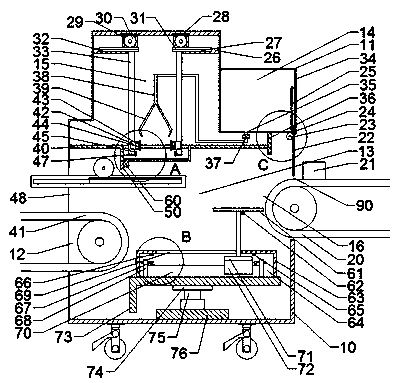

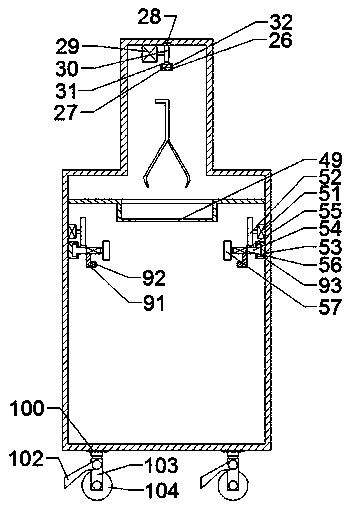

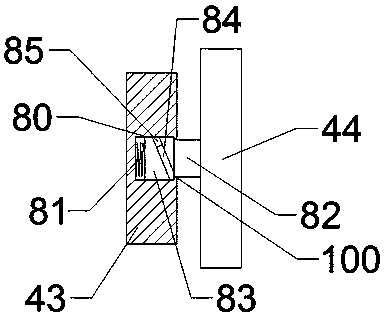

[0020] Combine below Figure 1-7 The present invention will be described in detail.

[0021] Reference Figure 1-7 , According to an embodiment of the present invention, a movable paint molding equipment and molding method, including a paint molding cabinet 10, the paint molding cabinet 10 has a paint cabinet 11 on the upper right side, and the paint cabinet 11 There is a paint storage cavity 14, the paint molding cabinet body 10 has a working cavity 13, and the upper side of the working cavity 13 has a paint spraying cavity 15, and the left side of the working cavity 13 has a material outlet cavity 12, and the working cavity 13 There is a sliding cavity 64 below, a material inlet cavity 16 is provided on the right side of the working cavity 13, the material inlet cavity 16 is provided with a workpiece inlet 90, and the workpiece inlet 90 is provided with a feeding conveyor belt 20, the feeding conveyor belt 20 The upper part is used to place the workpiece 21, the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com