Valve train and engine assembly

A valve train, engine technology, applied in engine components, machine/engine, engine control, etc., can solve problems such as large air exchange loss, and achieve the effect of eliminating tradeoffs and optimizing inflation motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

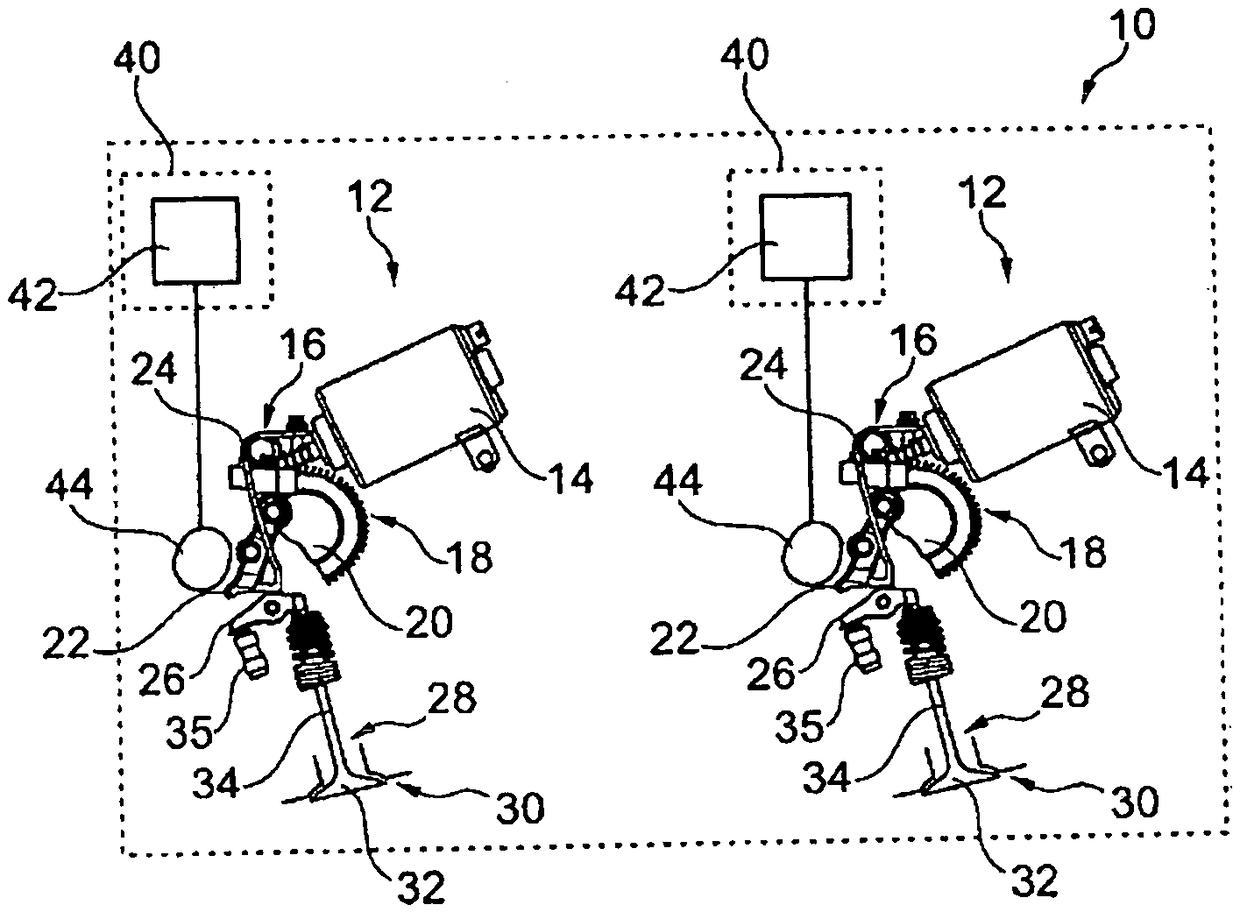

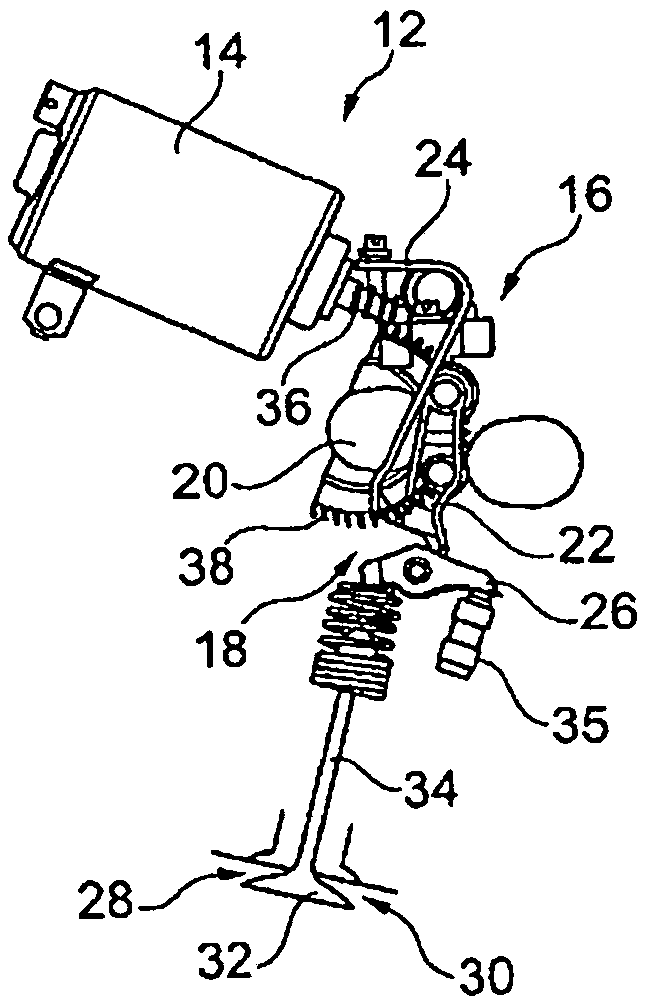

[0044] figure 1 A valve train 10 for a motor vehicle engine and its valves is shown. In the embodiment shown, the valve train 10 comprises two driven actuator units 12 which are not coupled to one another.

[0045] Each actuator unit 12 has its own electromechanical servo drive 14 and an actuator 16 comprising an adjusting shaft 18 with an adjusting cam 20 mounted thereon and an intermediate lever 22 acting on the adjusting cam 20 from the outside. . The intermediate lever 22 is prestressed onto the camshaft 44 via the return spring 24 . The intermediate lever 22 is driven by a camshaft 44 .

[0046] The adjusting shaft 18 can be an eccentric shaft, so that the at least one adjusting cam 20 is an eccentric wheel.

[0047] The intermediate lever 22 also drives the tug lever 26 , which operates the valve 28 with the valve seat 30 and the valve member 32 . The valve element 32 is coupled to the roller rod 26 via a valve lifter 34 . The valve element 32 and the valve lifter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com